Automatic packing production line based on improved delta robot

A technology of automatic boxing and robotics, applied in the directions of automatic packaging control, packaging, packaging protection, etc., can solve the problems of waste of manpower and material resources, inability to guarantee, difficulties, etc., and achieve the effect of high degree of automation, high uniformity of food specifications, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

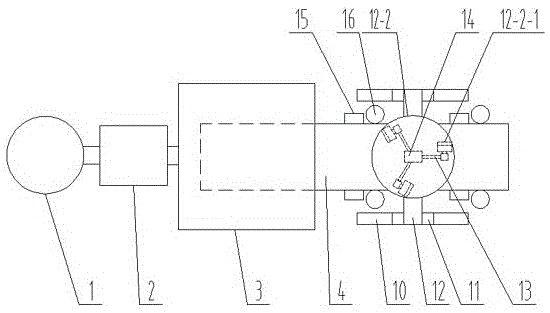

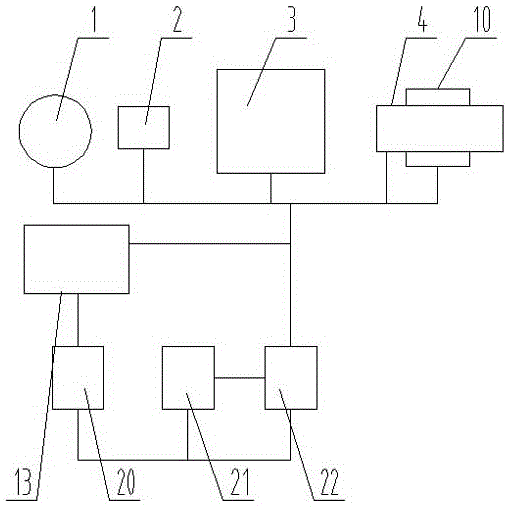

[0010] Such as figure 1 , 2 Shown, the present invention comprises mixer 1, fermenter 2, oven 3 and the conveyer belt 4 that is used to transport bread, and the feed port of fermenter 2 communicates with the outlet of mixer 1 by pipeline and valve, and oven 3 is used for baking Baking fermentation machine 2 fermented dough, it also has an automatic food boxing system, the food automatic boxing system consists of a base electric slide table 10, a pair of bases 11, a robot gantry frame 12, a six-degree-of-freedom delta robot 13, a rotary Pneumatic picking claw 14, robot vision control system 20, image contrast recognition system 21, production line control system 22, qualified product packaging box 15 and unqualified product collection box 16, a pair of slide rails of the base electric slide table 10 are respectively parallel to the conveyor belt 4 on both sides, and fixedly installed on the ground, a pair of bases 11 are respectively installed on the sliders on the pair of sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com