Multi-stage aerating biofilter

A technology of biological aerated filter and biological filter material, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The problems of single oxygen quantity method and fixed operation mode are beneficial to the distribution of dissolved oxygen, the purification effect is good, and the concentration of oxygen is uniform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

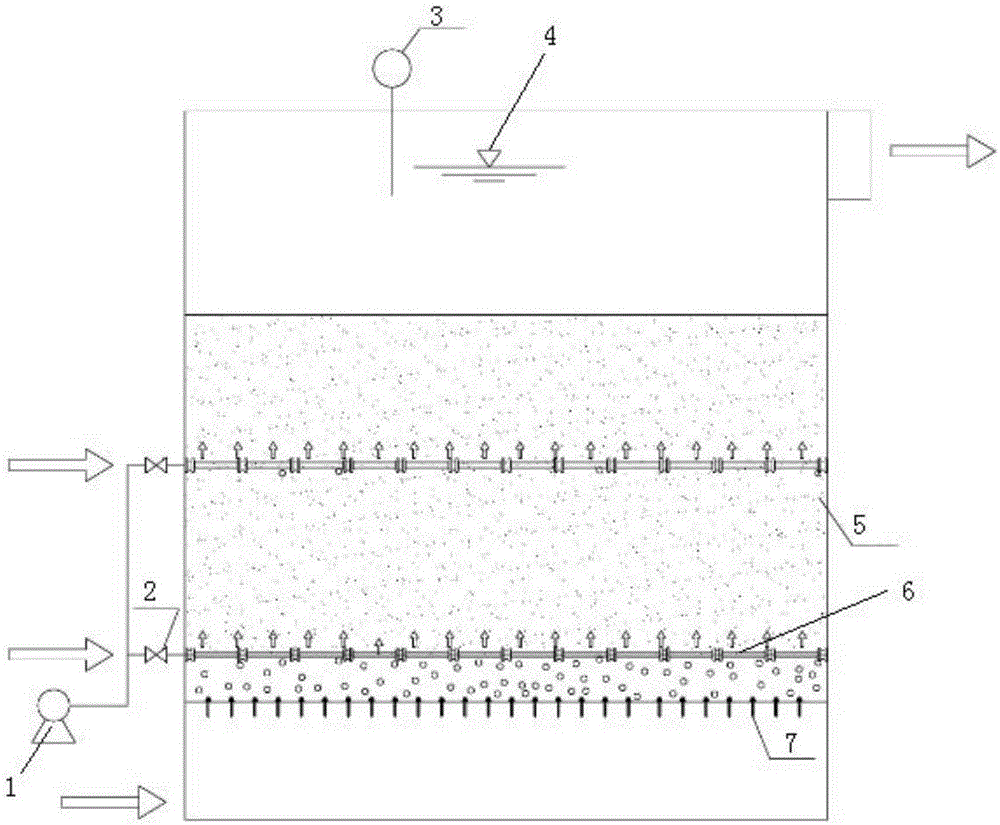

[0041] The multi-point aeration device has a mesh structure, and several aeration holes are evenly distributed on the mesh structure, and the direction of the aeration holes is obliquely upward. The multi-point aeration device communicates with the blower 1 through a valve. The network structure of the multi-point aeration device 6 is connected everywhere, and the network structure will not block the flow of water, and can provide uniform oxygen for anhydrous.

[0042]A dissolved oxygen meter 3 is arranged in the liquid surface of the water outlet area. Both the blower 1 and the dissolved oxygen meter 3 are connected to the control system, and the dissolved oxygen meter 3 transmits the dissolved oxygen concentration signal to the control system, and the control system controls the blower 1 to be turned on or off by comparing the measured value with the set value.

[0043] The multi-point aeration device 6 has two layers, and the two layers of multi-point aeration devices 6 ar...

Embodiment 2

[0063] The multi-point aeration device 6 is composed of a number of aeration pipes connected to each other and arranged in parallel. Many aeration holes are evenly distributed on the aeration pipes, and the direction of the aeration holes is upward. The number of layers of multi-point aeration device 6 is 3 layers, also can be 4 layers, 5 layers, concrete several layers are determined according to specific conditions. These layers of multi-point aeration devices 6 are evenly distributed in the filter layer, and the biological filter material is filled in the entire filter layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com