A new type of anti-corrosion coating for water pipe elbows

A technology for anti-corrosion coatings and water pipes, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of easy corrosion leakage, long time, waste of manpower and material resources, etc., and achieve strong acid or alkali corrosion resistance, The formula is novel and reasonable, and it is not easy to corrode and leak.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

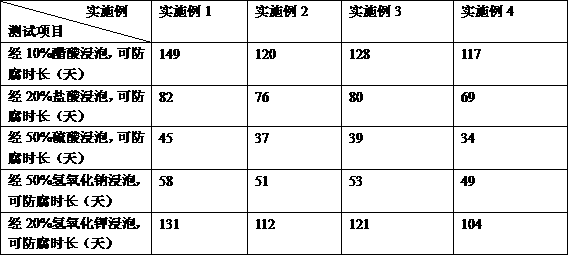

Examples

Embodiment 1

[0031] A new type of anti-corrosion coating for water pipe elbow, its preparation method is as follows:

[0032] (1) Organic material treatment

[0033] ① Put 32 parts by mass of isocyanate into the reaction kettle, stir at 170r / min, and gradually add 19 parts by mass of amino resin to obtain a reaction mixture;

[0034] ②The mixed reactant obtained in step (1)① is stirred at a rate of 200r / min, the reaction temperature is controlled to 72-76°C, and the reaction is conducted for 3.5 hours to obtain a reactive polymer;

[0035] ③ Stir at a rate of 300r / min, gradually add 8 parts by mass of biuret to the reaction kettle and mix with the reaction polymer obtained in step (1) ②. After the biuret is added, control the temperature to 48 -53℃, stir for 50min at a rate of 150r / min to obtain organic paint;

[0036] (2) Treatment of inorganic materials

[0037] ① Grind 7 parts by mass of zinc oxide particles into fine zinc oxide powder through a grinder;

[0038] ②Add the zinc oxide fine powder ob...

Embodiment 2

[0046] A new type of anti-corrosion coating for water pipe elbow, its preparation method is as follows:

[0047] (1) Organic material treatment

[0048] ① Put 33 parts by mass of isocyanate into the reactor, stir at a rate of 180r / min, and gradually add 25 parts by mass of amino resin to obtain a reaction mixture;

[0049] ②The mixed reactant obtained in step (1)① is stirred at a rate of 140r / min, the reaction temperature is controlled to be 75-79°C, and the reaction is carried out for 4.5 hours to obtain a reactive polymer;

[0050] ③ Stir at a rate of 320r / min, gradually add 8 parts by mass of biuret to the reaction kettle, and mix with the reaction polymer obtained in step (1) ②. After the biuret is added, control the temperature to 47. -50℃, stir for 50min at a rate of 190r / min to obtain organic paint;

[0051] (2) Treatment of inorganic materials

[0052] ① Grind 6 parts by mass of zinc oxide particles into fine zinc oxide powder through a grinder;

[0053] ②Add the zinc oxide fine ...

Embodiment 3

[0060] A new type of anti-corrosion coating for water pipe elbow, its preparation method is as follows:

[0061] (1) Organic material treatment

[0062] ①Put 26 parts by mass of isocyanate into the reaction kettle, stir at 230r / min, and gradually add 32 parts by mass of amino resin to obtain a reaction mixture;

[0063] ②The mixed reactants obtained in step (1)① are stirred at a rate of 210r / min, the reaction temperature is controlled to 73-76°C, and the reaction is conducted for 3.5 hours to obtain a reaction polymer;

[0064] ③ Stir at a rate of 320r / min, gradually add 7 parts by mass of biuret into the reactor, and mix with the reaction polymer obtained in step (1) ②. After the biuret is added, control the temperature to 43 -46℃, stir for 45min at a rate of 260r / min to obtain organic paint;

[0065] (2) Treatment of inorganic materials

[0066] ① Grind 7 parts by mass of zinc oxide particles into fine zinc oxide powder through a grinder;

[0067] ②Add the zinc oxide fine powder obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com