High-strength bolt and its manufacturing method

A high-strength bolt and bolt technology, applied in the field of bolt processing, can solve the problems of plasticity and toughness that cannot reach high-strength bolts, and achieve the effect of improving service life, safe and reliable connection, and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

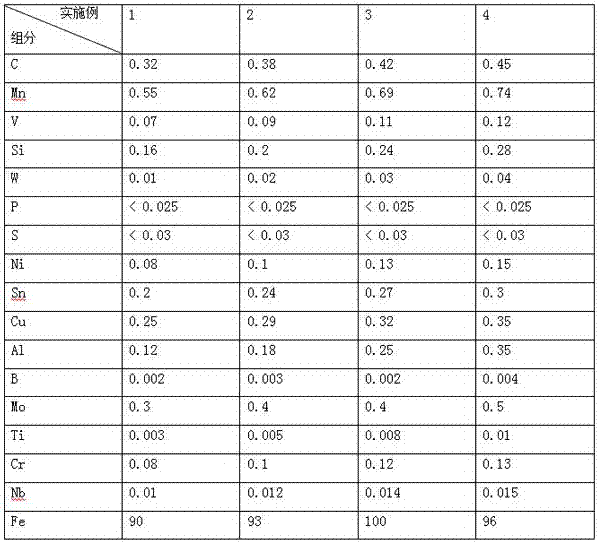

[0023] Select the steel plate of Example 1 in Table 1 with chemical composition and mass percentage ratio, and the specific processing steps are as follows:

[0024] (1) Material preparation: Select the steel plate with the above composition to be pickled and derusted, and cut a cylindrical blank of appropriate size according to the specification of the bolt;

[0025] (2) Softening annealing; softening annealing is divided into two times, specifically: first softening annealing: the billet is subjected to isothermal softening annealing in a bell furnace, the softening annealing temperature is 750 ° C, the holding time is 7 hours, and its hardness is controlled at less than HB120, control methanol flow rate 25ml / min, gas flow rate 0.2Nm3 / h to prevent surface carburization; secondary softening annealing: annealing temperature is 650℃, time 5h, alcohol flow rate 20ml / min, gas flow rate 0.2Nm3 / h;

[0026] (3) Cold forging forming: cut the annealed cylindrical raw material to the r...

Embodiment 2

[0033] Select the steel plate of Example 2 in Table 1 with chemical composition and mass percentage ratio, and the specific processing steps are as follows:

[0034] (1) Material preparation: Select the steel plate with the above composition to be pickled and derusted, and cut a cylindrical blank of appropriate size according to the specification of the bolt;

[0035] (2) Softening annealing; softening annealing is divided into two times, specifically: first softening annealing: the billet is subjected to isothermal softening annealing in a bell furnace, the softening annealing temperature is 800 ° C, the holding time is 8 hours, and its hardness is controlled at less than HB120, control methanol flow rate 30ml / min, gas flow rate 0.25Nm3 / h to prevent surface carburization; secondary softening annealing: annealing temperature is 700℃, time 6h, alcohol flow rate 25ml / min, gas flow rate 0.25Nm3 / h;

[0036] (3) Cold forging forming: cut the annealed cylindrical raw material to the...

Embodiment 3

[0043] Select the steel plate of Example 3 in Table 1 with chemical composition and mass percentage ratio, and the specific processing steps are as follows:

[0044] (1) Material preparation: Select the steel plate with the above composition to be pickled and derusted, and cut a cylindrical blank of appropriate size according to the specification of the bolt;

[0045] (2) Softening annealing; softening annealing is divided into two times, specifically: first softening annealing: the billet is subjected to isothermal softening annealing in a bell furnace, the softening annealing temperature is 780 ° C, the holding time is 7.5 hours, and its hardness is controlled at less than HB120, control methanol flow rate 30ml / min, gas flow rate 0.22Nm3 / h to prevent surface carburization; secondary softening annealing: annealing temperature is 680°C, time 5.5h, alcohol flow rate 23ml / min, gas flow rate 0.22Nm3 / h ;

[0046] (3) Cold forging forming: cut the annealed cylindrical raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com