Soldering-resistance conductive thin film on surface of sensitive structure of space electrostatic accelerometer and production technology thereof

A sensitive structure and accelerometer technology, which is applied in the field of precision equipment for space science loads, can solve problems such as damaged electrode pads, difficult sensor assembly, and easy breakage of electrode leads, achieving small linear expansion coefficients, ensuring stability, and good matching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the embodiments. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0035] A solder-resistant conductive film on the surface of the sensitive structure of a space electrostatic accelerometer, which is a three-layer composite film system: Ti-Pt-Au, wherein the thickness of the Ti film of the adhesive layer is generally controlled at 40-60nm, and the thickness of the Pt film of the intermediate transition layer It is controlled at 600nm-1000nm, and the thickness of the conductive protective Au film is controlled at 100-200nm.

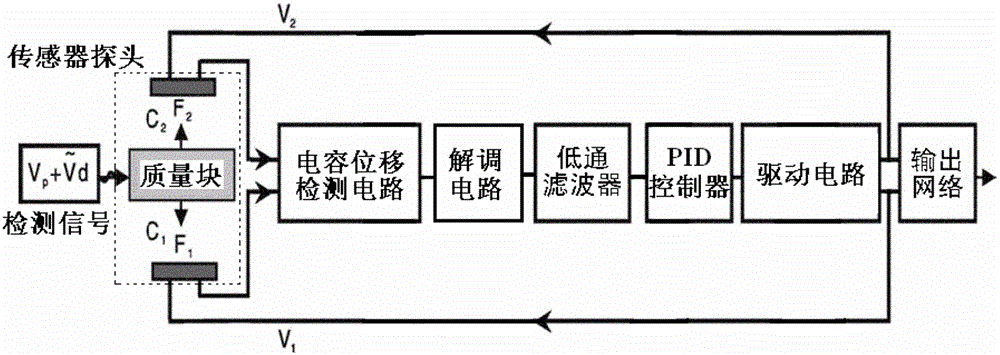

[0036] Taking the sensitive structure of the sensor of the electrostatic levitation accelerometer as an example, the fabrication process of the solder-resistant conductive film on its surface is introduced.

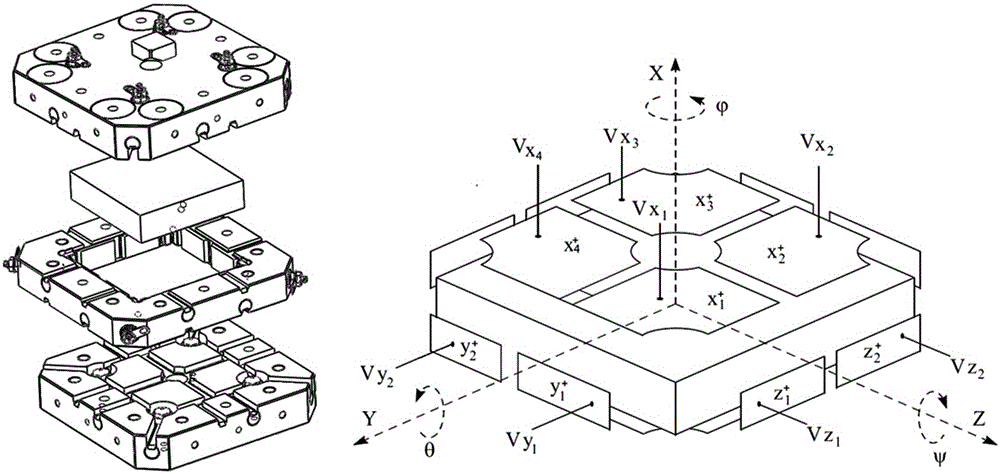

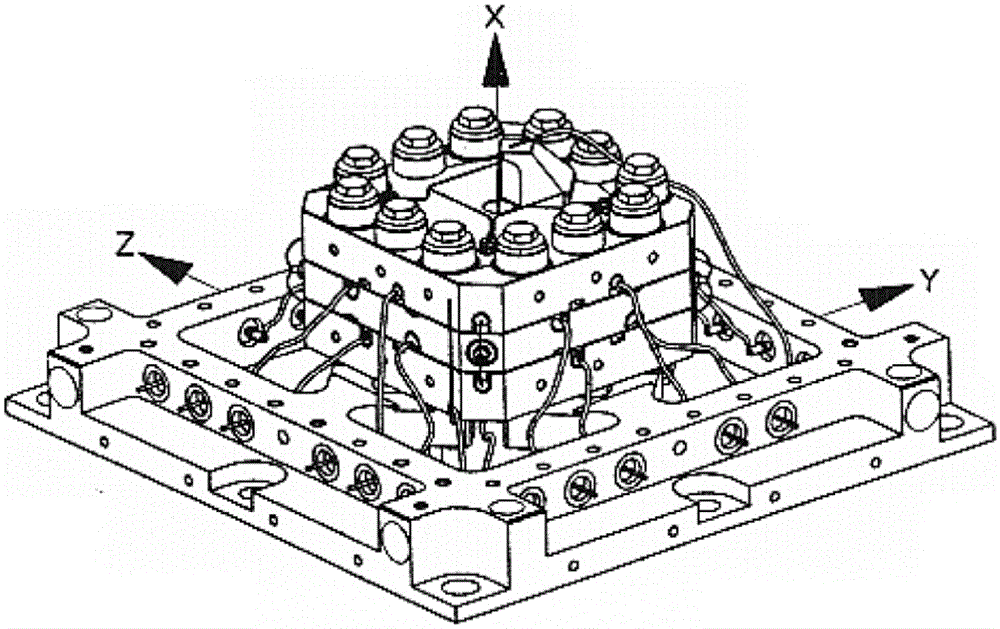

[0037] The sensor sensitive structural components of the elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com