Combined electromachining method for bamboo-like micro-structure of rotating body inner surface

A technology of rotating body and inner surface, applied in the direction of electroforming, electrolysis process, etc., can solve the problems of not meeting the size requirements of fine and narrow grooves, deformation of micro ribs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

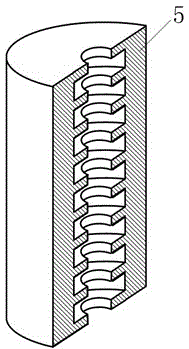

[0026] The bamboo-shaped microstructure (non-special-shaped structure) on the inner surface of the rotator that needs to be prepared is as follows: image 3 As shown, the following preparation process is adopted:

[0027] Step 1. Prepare hollow aluminum rods and hollow copper rods with an inner diameter of d1 and an outer diameter of d2:

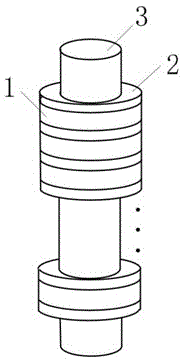

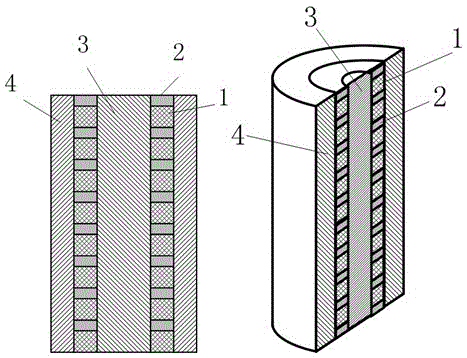

[0028] Step 2, processing the hollow aluminum rod in step 1 into several aluminum ring sheets 1 with a thickness of L1 through wire electric discharge cutting, and processing the hollow copper rod into several copper ring sheets 2 with a thickness of L2;

[0029] Step 3, the aluminum mandrel 3 adopts a solid aluminum rod, and the aluminum ring sheet 1 and the copper ring sheet 2 processed in step 2 are nested on the solid aluminum rod with a diameter of d1 in the order of the aluminum ring-copper ring multi-layer separation ;

[0030] Step 4, electroforming copper processing on the solid aluminum rod nested with the aluminum ring sheet 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com