Water stopping method applied to joint of hydropower station and water stopping structure thereof

A hydropower station and water-stopping technology, which is applied in water conservancy projects, marine engineering, construction, etc., can solve problems such as unsatisfactory water-stopping effects, damage to concrete panels, and poor structural stability, so as to improve airtightness and water-stopping effects, and water-stopping Good effect and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

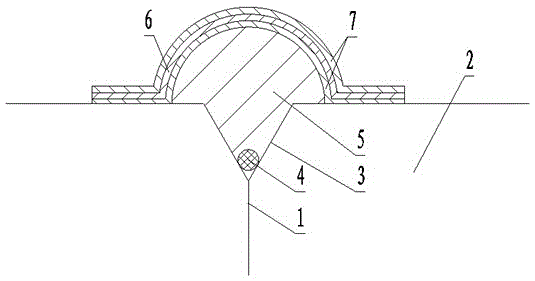

[0019] Embodiment one. like figure 1 As shown, the seam sealing method used in hydropower stations includes the following steps:

[0020] a. Surface treatment, surface treatment is carried out on the concrete panel 2 at the joint 1, so that the surface of the concrete panel 2 within 13-20 cm on both sides of the joint 1 is flat and dry;

[0021] b. Install the rubber rod 4, fill the rubber rod 4 with a diameter of 10-15mm along the seam 1 to the bottom of the seam reserved groove 3;

[0022] c. Filler embedding, insert the plastic filler 5 into the seam reserved groove 3;

[0023] d. Scrape polyurea elastomer 7, use a sawtooth-shaped scraper to evenly scrape a layer of polyurea elastomer 7 on the surface of the concrete surface 2 and plastic filler 5 within 13 to 20 cm on both sides of the joint 1; then Adhere the base fabric 6 on the surface of the layer of polyurea elastomer 7, and finally scrape several layers of polyurea elastomer 7 evenly on the surface of the base fab...

Embodiment 2

[0026] Embodiment two. like figure 1 As shown, the seam sealing method used in hydropower stations includes the following steps:

[0027] a. Surface treatment. Surface treatment is carried out on the concrete panel 2 at the joint 1. First, use a putty knife and a wire brush to clean the loose concrete blocks in contact with the filler. Then use an angle grinder to grind and level; finally rinse with water to remove dust and dry, so that the surface of the concrete panel 2 within 13cm on both sides of the joint 1 is smooth, dense and dry;

[0028] b. Install the rubber rod 4, fill the rubber rod 4 with a diameter of 12 mm to the bottom of the seam reserved groove 3 along the seam 1;

[0029] c. Filler embedding, insert the plastic filler 5 into the seam reserved groove 3;

[0030] d. Scrape polyurea elastomer 7 (such as SK hand-scraped polyurea), use a sawtooth-shaped scraper to evenly scrape a layer of polyurea on the surface of the concrete surface 2 and plastic filler 5 w...

Embodiment 3

[0033] Embodiment three. like figure 1 As shown, the seam sealing method used in hydropower stations includes the following steps:

[0034] a. Surface treatment. Surface treatment is carried out on the concrete panel 2 at the joint 1. First, use a putty knife and a wire brush to clean the loose concrete blocks in contact with the filler. Then use an angle grinder to grind and level; finally rinse with water to remove dust and dry, so that the surface of the concrete panel 2 within 13cm on both sides of the joint 1 is smooth, dense and dry;

[0035] b. Install the rubber rod 4, fill the rubber rod 4 with a diameter of 12 mm to the bottom of the seam reserved groove 3 along the seam 1;

[0036] c. Filler embedding, insert the plastic filler 5 into the seam reserved groove 3;

[0037] d. Scrape polyurea elastomer 7 (such as SK hand-scraped polyurea), use a sawtooth-shaped scraper to evenly scrape a layer of polyurea on the surface of the concrete surface 2 and plastic filler 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com