Method for identifying combustion model of circulating fluidized bed on basis of least squares

A circulating fluidized bed and least squares technology, which is applied in the direction of combustion methods, combustion control, and fuel supply adjustment, can solve problems such as low pollution and utilization rate, and achieve strong generalization, improved model accuracy, and improved response The effect of speed and positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention, concrete steps comprise:

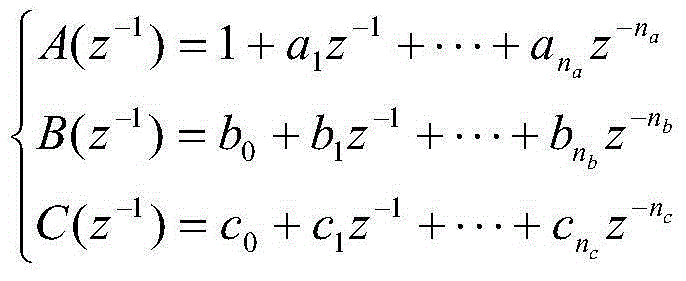

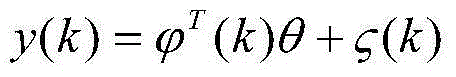

[0019] Step 1, consider the CARMA model of the random process, and convert the model into a least squares structure;

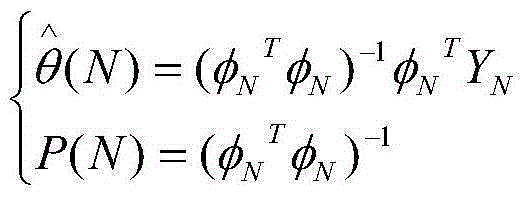

[0020] Step 2, according to the one-step and recursive algorithm of basic least squares, establish parameter estimation for the circulating fluidized bed combustion process, and set the initial value of the algorithm;

[0021] Step 3, determine the sampling period T, and import the fuel quantity (input) and steam pressure (output) data of the supply boiler in the circulating fluidized bed combustion process;

[0022] Step 4. According to the recursive algorithm of basic least squares estimation, perform parameter recursive estimation and calculate and P(k);

[0023] Step 5, return to step (c), and import the input and output data again until the algorithm converges or meets the requirements.

[0024] In the application of the CARMA model to a circulating fluidized bed combustion process, the structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com