PLC software programming aided design method

An auxiliary design and software programming technology, applied in the direction of program control devices, etc., can solve the problems of random variable definition, error-prone, time-consuming and labor-intensive problems, and achieve the effects of reducing the workload of program development, ensuring standardization, and simplifying the PLC programming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

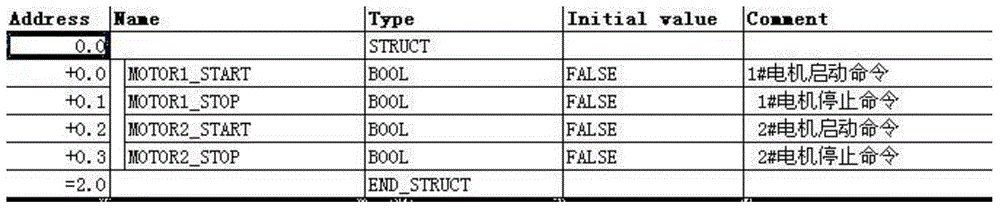

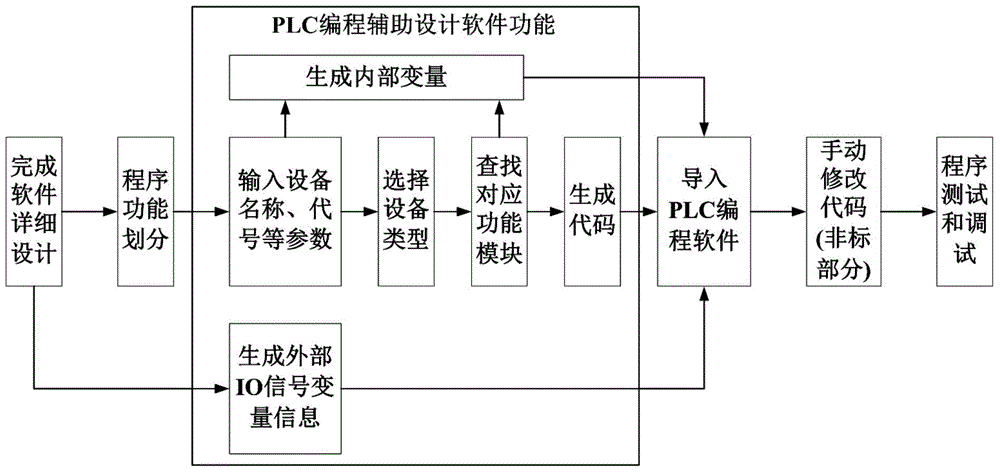

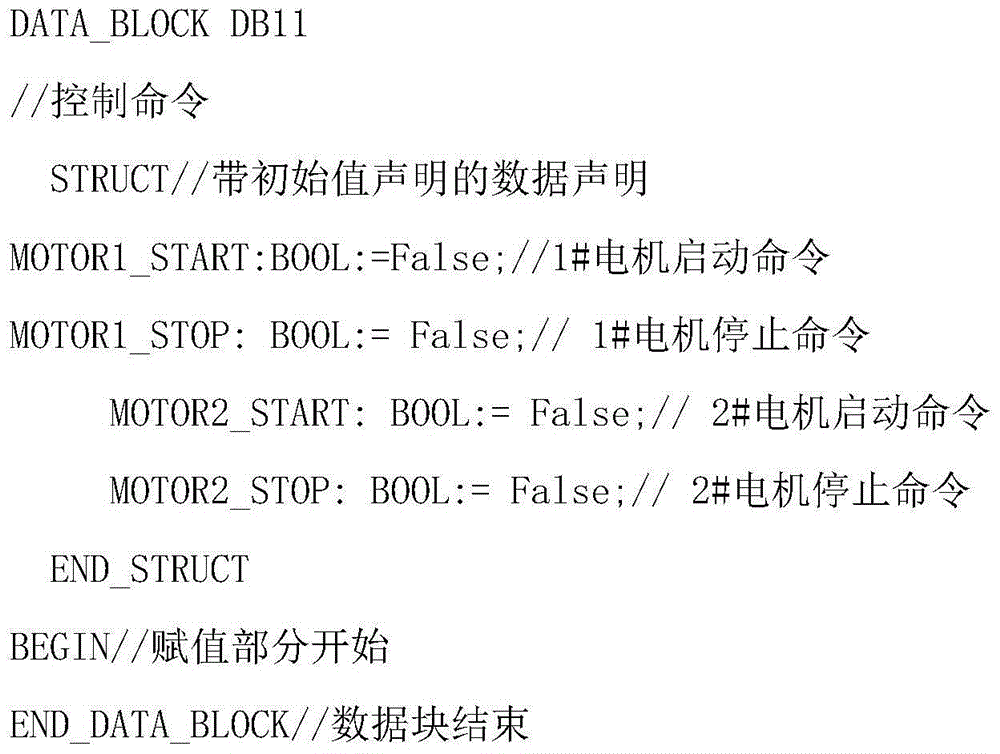

Method used

Image

Examples

Embodiment 1

[0037] Example 1: A company's central substation control system is transformed, and a new Siemens S7-300PLC control system is added to realize the status monitoring and remote control of power equipment such as switches, switches and transformers in the substation. The total number of external IO points is about 800 points, plus about 1200 points of internal variables in the middle of the program. The program involves a total of 100 electrical equipment control circuits and related alarm interlocks. According to the general software development method, the PLC software development of this scale takes about 4-5 weeks. By using the PLC software programming aided design method of the present invention, the programming of the PLC software can be completed in only three working days, and the accuracy rate of the PLC program is proved to be extremely high through post-test and on-site debugging.

Embodiment 2

[0038]Example 2: Software development of the control system of the second hot rolling gas mixing and pressurizing station of a company, adding a Siemens S7-400H control system to monitor the status of three gas compressors, a large and small tube gas mixing device and related auxiliary equipment and remote control. The system scale includes more than 300 external IO points and more than 1,000 internal IO point variables, and the program involves a total of 111 calls of function modules. According to the general software development method, the PLC software development of this scale takes about 3-4 weeks. By using the PLC software programming aided design method of the present invention, the programming of the PLC software can be completed in only four working days, and the accuracy rate of the PLC program is proved to be extremely high through post-test and on-site debugging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com