Optical fiber output large-power semiconductor laser module

A technology of lasers and semiconductors, applied in semiconductor lasers, the structural details of semiconductor lasers, lasers, etc., can solve problems such as low coupling efficiency, and achieve the effect of improving coupling efficiency and reducing the impact of reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

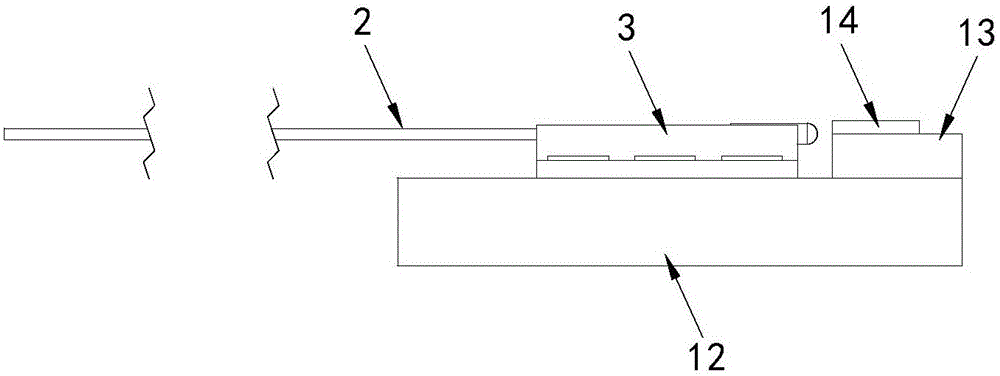

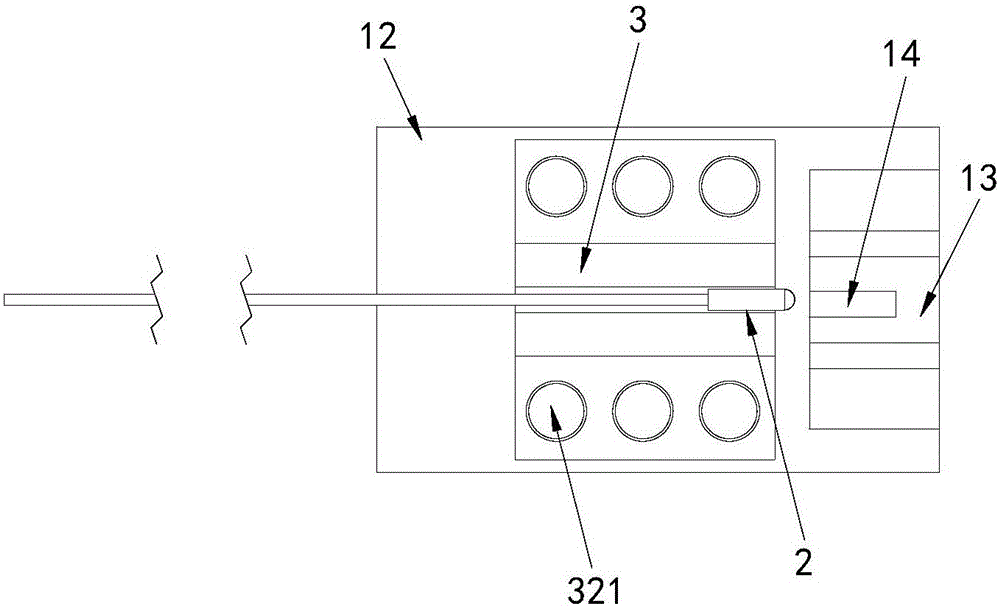

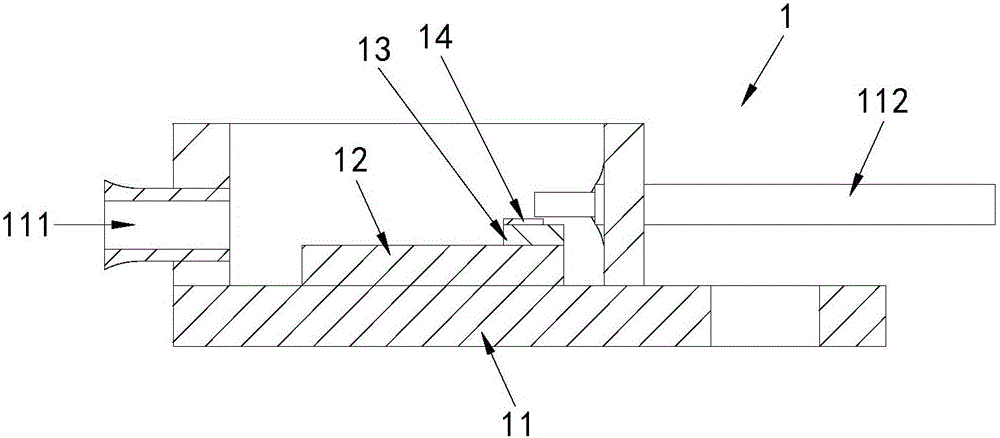

[0034] As a specific embodiment, the welding bracket 12, the AlN heat sink 13 and the laser chip 14 are fixed by welding with metal solder. As an embodiment, Au80Sn20 (gold-tin alloy) solder is used for welding between the laser chip 14 and the AlN heat sink 13, and PbSn (lead-tin alloy) solder is used for welding between the AlN heat sink 13 and the welding bracket 12, In (indium) solder is used for welding between the welding bracket 12 and the metal tube shell 11, thereby realizing that all components inside the metal tube shell 11 are fixed by metal solder welding, that is, a gel-free welding fixation is realized, thereby The impact of organic volatilization on the reliability of laser chips is reduced. In particular, Au80Sn20 solder is used for welding between the laser chip 14 and the AlN heat sink 13, and Au80Sn20 solder has relatively stable characteristics under high and low temperature cycle conditions, so effective welding between the laser chip 14 and the AlN heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com