Pulping method and pulping equipment for producing Fu tea

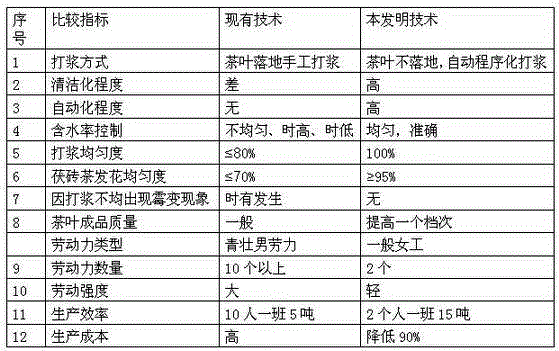

The technology of Fucha tea and equipment is applied in the field of beating and beating equipment for producing Fucha tea, which can solve the problems of increased production cost, high labor intensity, low production efficiency, etc., and achieves the effects of reduced production cost, high degree of automation, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: the technical solution of the beating method of producing Fu tea is: take the following steps:

[0017] a. Material transportation: Send the blended tea raw materials into the silo;

[0018] b. Brewing tea juice: put it into the cooking pot for 1-2 hours according to the ratio of the weight ratio of tea stem to water: 1:50-150, then filter the tea juice and put it into the tea juice tank;

[0019] c. Feeding: Put the tea raw materials into the mixer quantitatively from the feeding port of the silo;

[0020] d. Automatic beating: use an automatic programmed beating machine to extract tea juice from the tea juice tank and spray the slurry water quantitatively to the tea raw materials in the mixer. The weight of the sprayed slurry water is controlled at 20-35% of the tea weight;

[0021] e. Automatic stirring: the tea raw materials are stirred in the blender while beating, and the stirring time is controlled at 0.5-2 minutes until the pulp is evenly distribu...

Embodiment 2

[0023] Embodiment 2: the technical solution of the beating method of producing Fu tea is: take the following steps:

[0024] a. Material transportation: Send the blended tea raw materials into the silo;

[0025] b. Brewing tea juice: Put the tea stem in a steaming pot according to the weight ratio of 1:80-120 or 1:90-100 to water, and after 1-2 hours, filter the tea juice and put it into the tea juice tank;

[0026] c. Feeding: Put the tea raw materials into the mixer quantitatively from the feeding port of the silo, and the automatic metering and automatic feeding method can be adopted;

[0027] d. Automatic beating: Use an automatic programmed beating machine to extract tea juice from the tea juice tank and spray the slurry water quantitatively to the tea raw materials in the mixer. The weight of the sprayed slurry water is controlled at 25-32% of the tea weight, or 28-30% %;

[0028] e. Automatic stirring: the tea raw materials are stirred in the blender while beating, an...

Embodiment 3

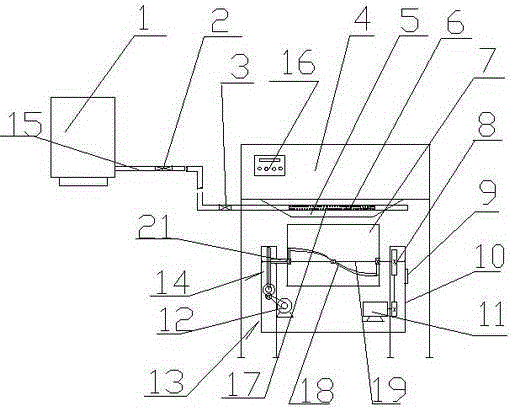

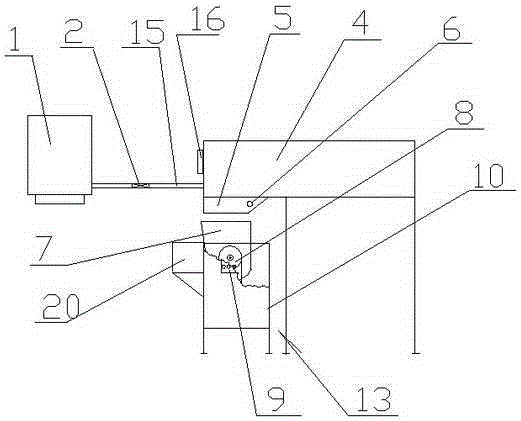

[0030] Embodiment 3: as Figure 1-2 Shown: the beating equipment for the production of Fu tea is provided with a silo 4, and the hopper 4 is provided with a hopper 5, and an up and down mixer 13 is arranged under the hopper 5, and a vertical agitator is provided between the silo 4 and the mixing barrel 7 of the mixer 13. The barrel implements the spraying pipe 6 for spraying slurry water quantitatively, the spraying pipe 6 is provided with the flow control valve 3 controlled by the flow controller 16, the spraying pipe 6 is connected with the tea juice delivery pipe 15, and the tea juice delivery pipe 15 is connected with the tea juice delivery pipe 15. Barrel 1 is connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com