VOCS waste gas treatment device and VOCS waste gas treatment method

A waste gas treatment device and technology for waste gas treatment, which are applied in combustion methods, separation methods, chemical instruments and methods, etc., can solve the problems of low treatment efficiency, reduce the purity index of exhaust gas, and high energy consumption, and achieve the goal of improving the purity index and avoiding thermal energy. Loss, the effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

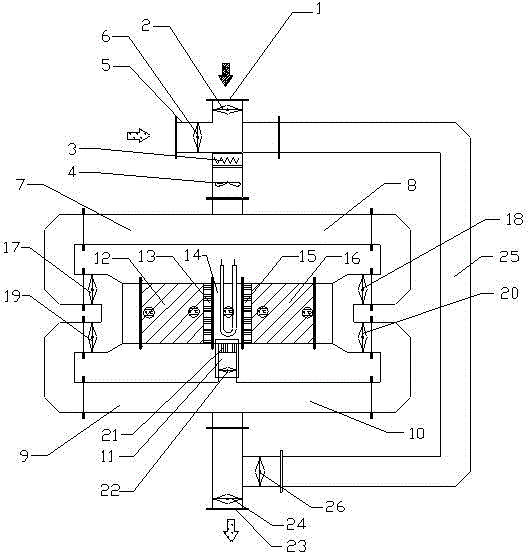

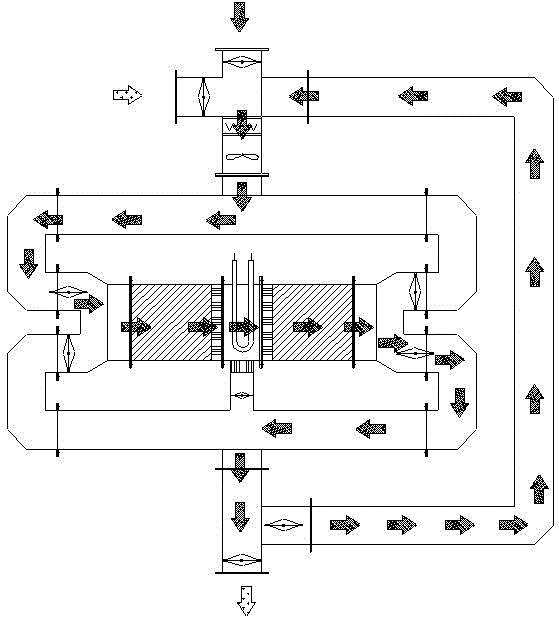

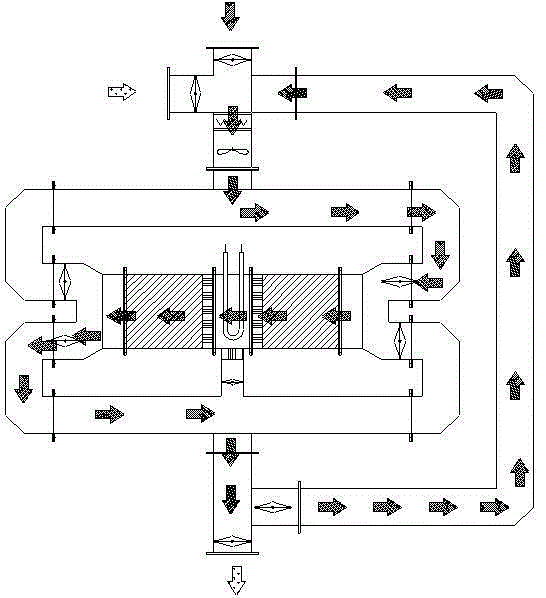

[0052] see figure 1 , a kind of VOCS exhaust gas treatment device that the present invention relates to, it comprises inlet section, intermediate treatment section and outlet section, the rear end of inlet section is connected with the front end of intermediate treatment section, the rear end of intermediate treatment section is connected with the front end of outlet section, The front end of the inlet section is the VOCS sewage outlet interface 1, the front section of the inlet section is provided with a general inlet valve 2, the rear section of the inlet section is provided with a filter 3 and a main fan 4 in sequence from front to back, and the middle section of the inlet section is connected with a fresh air inlet Section 5, fresh air inlet section 5 is provided with a fresh air valve 6 .

[0053] The intermediate treatment section comprises a first reaction chamber inlet pipeline 7, a second reaction chamber inlet pipeline 8, a reaction chamber, a first reaction chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com