Automation system for removing soil pollutants

An automation system and pollutant technology, applied in the field of automation systems, can solve the problems of high cost of off-site treatment, high equipment investment cost, slow repair rate, etc., to control the quality of tail gas treatment, increase the amount of tail gas treatment, and prevent liquid backflow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

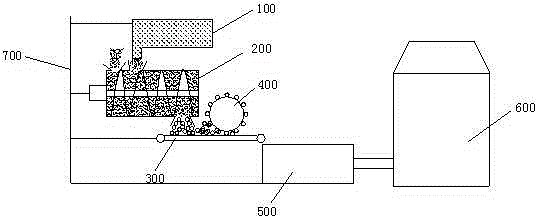

[0037] Such as figure 1 Shown is a structural diagram of the soil pollution remediation equipment described in the present invention.

[0038] Such as figure 1 As shown, an automatic system for removing soil pollutants includes a soil stirring device 200, the soil stirring device 200 is provided with a feed inlet and a discharge port, and the top of the feed inlet is provided with a sorbent feeding hopper 100; a conveyor 300 is provided below the discharge port, and a magnetic separation device 400 is provided on the conveyor 300; a soil liquefaction device 500 is provided below the end of the conveyor 300; the soil liquefaction device 500 passes through the pipeline and the soil restoration equipment 600 connect;

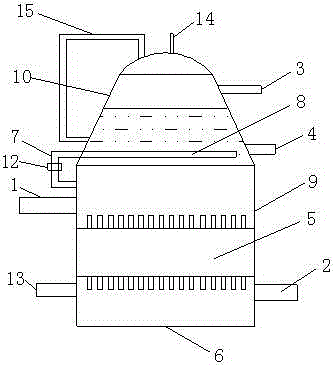

[0039] Such as figure 2 As shown, the soil remediation equipment 600 includes a shell, and the inside of the shell is divided into upper and lower parts by a partition, which are respectively the tail gas treatment pool 10 at the upper part of the equipment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com