Anti-dazzle glass and preparation method thereof

A technology of anti-glare glass and glass flakes, which is applied in glass manufacturing equipment, glass tempering, glass cutting devices, etc. It can solve the problems of light transmittance reduction, uneven quality of anti-glare glass, glass hardness, glass appearance, and glass decontamination. The performance has not been greatly improved to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

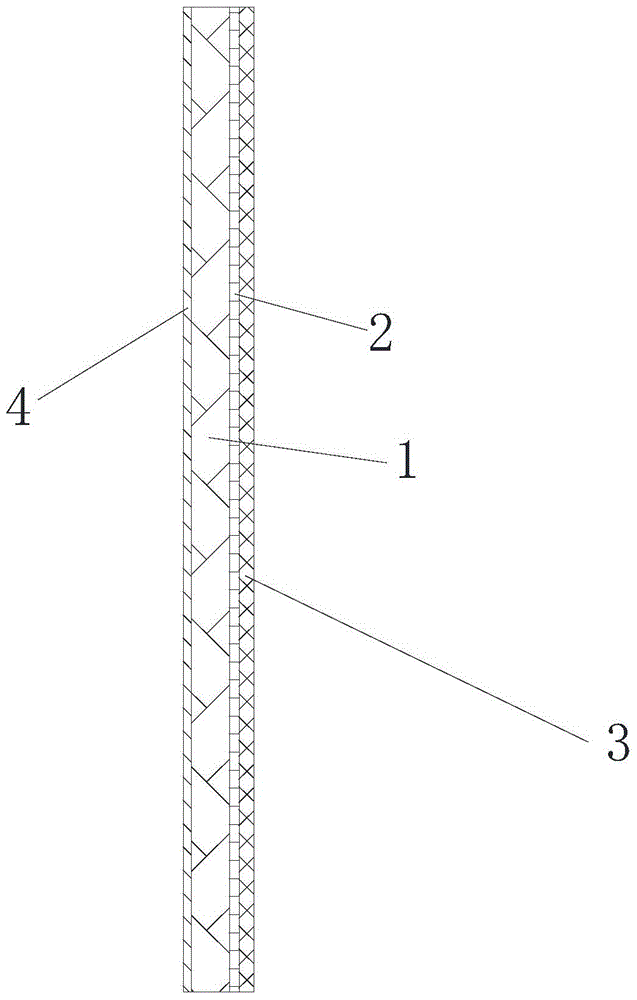

[0026] The invention discloses an anti-glare glass. The anti-glare glass comprises a glass substrate 1, the glass substrate 1 is divided into a smooth surface and a rough surface, the smooth surface is provided with a screen printing layer 4, and the rough surface is provided with an anti-reflection film layer 2. The anti-reflection layer 2 is provided with an anti-fouling layer 3 .

[0027] The invention also discloses a preparation method of the anti-glare glass, and the preparation steps are divided into six steps, namely: preparation of glass substrate 1, forming and processing of glass substrate 1, tempering treatment of glass substrate 1, precision printing process, and precision coating process and antifouling treatment process.

[0028] The specific operation method of each step is as follows:

[0029] Step 1: Preparation of glass substrate 1

[0030] For the preparation of the glass substrate 1, ordinary silica glass flakes are selected as raw materials, and the gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com