Device for producing hydrogen with solid fuel chemical chains and application

A solid fuel, chemical chain technology, used in the gasification of granular/powder fuel, the manufacture of combustible gas, the petroleum industry, etc., to achieve the effect of reducing investment costs, fast reaction rate, and maintaining continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

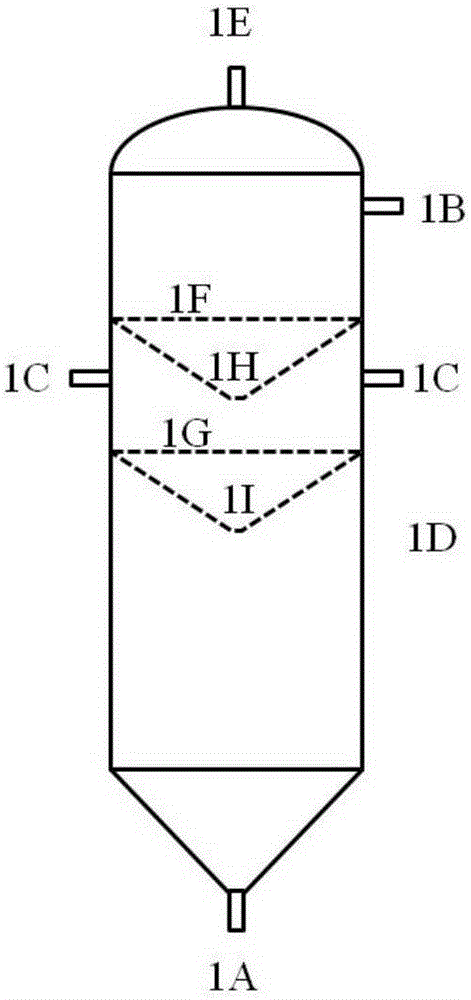

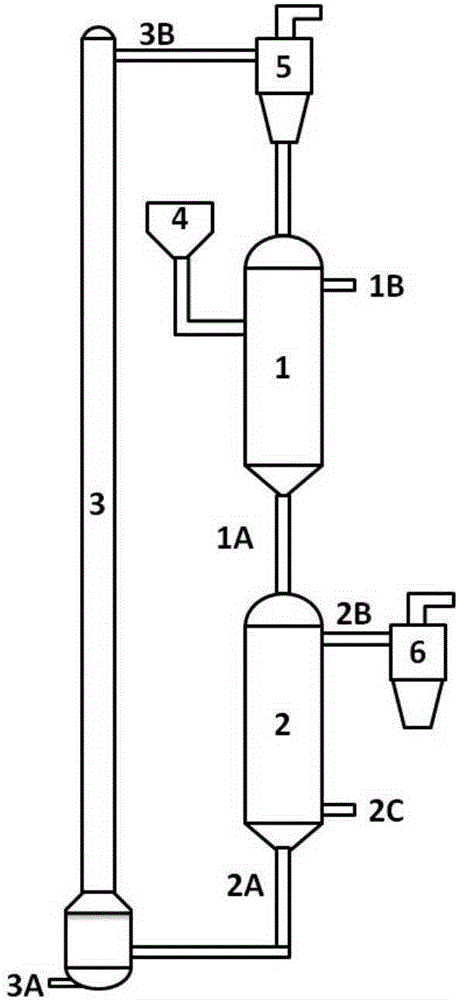

[0028] A device for solid fuel chemical chain hydrogen production, which includes a fuel reactor 1, a steam reactor 2, an air reactor 3 and a first cyclone separator 5, a second cyclone separator 6, characterized in that the fuel reactor The first solid fuel feed port 1C in the middle of 1 is connected to the feed bin 4, the top oxygen carrier inlet 1E is connected to the bottom outlet of the first cyclone separator 5, and the bottom first solid product outlet 1A is connected to the top of the steam reactor 2 through a non-mechanical valve The bottom of steam reactor 2 is provided with water vapor inlet 2C, and the top is provided with gas product outlet 2B, and gas product outlet 2B is communicated with the second cyclone separator 6, and the second solid product outlet 2A at the bottom is connected with air reactor 3 through non-mechanical valve The bottom is connected; the bottom of the air reactor 3 is provided with an air inlet 3A connected to the air distribution plate, a...

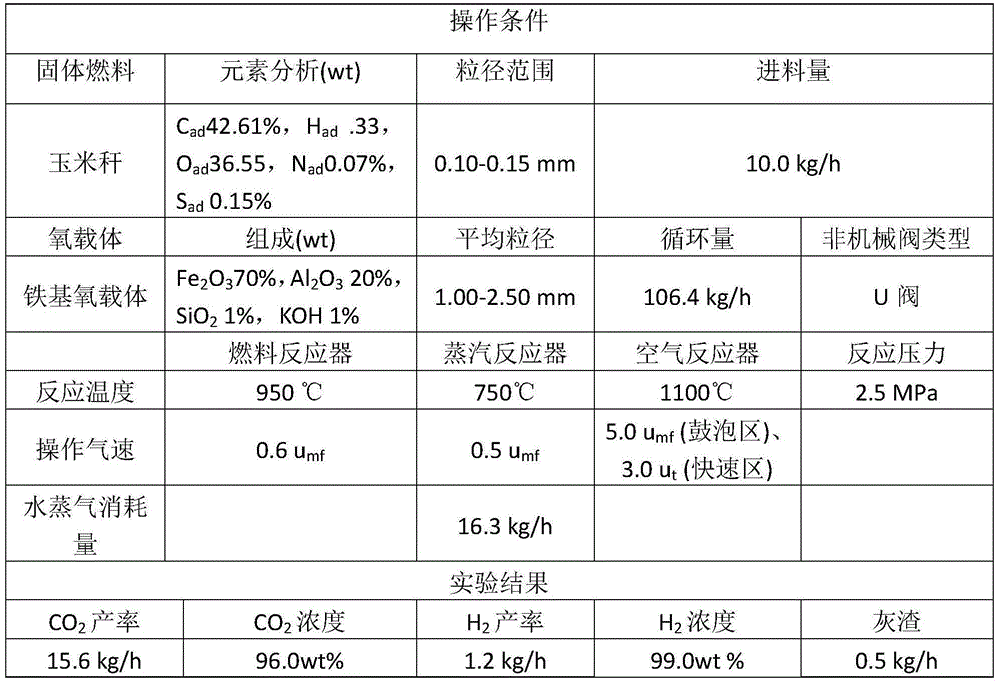

Embodiment 2

[0034] Since the operation steps of each embodiment are the same, the specific steps are not repeated here, and only the operation conditions and experimental results are listed.

[0035]

Embodiment 3

[0037] Since the operation steps of each embodiment are the same, the specific steps are not repeated here, and only the operation conditions and experimental results are listed.

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com