Method for extracting fat oil in croton by using ionic liquid

A technology of ionic liquid and fatty oil, which is applied in the direction of fat production, fat oil/fat production, and pharmaceutical formulations. It can solve the problems of waste of medicinal material resources, inability to fully extract effective ingredients such as croton oil, and a large proportion of croton. It is easy to recycle and good Dissolvability and the effect of less loss of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

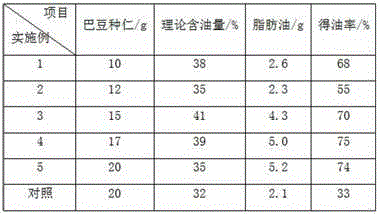

Examples

Embodiment 1

[0021] A method utilizing ionic liquid to extract fatty oil in croton comprises the following steps:

[0022] (1) Peel the croton seeds, take 10 g of the seed kernels, process them, and crush them to obtain processed crotons; the processing method is as follows: heat an empty pot, stir-fry the croton kernels, and fry until the cross-section of the croton kernels is When the yellow-white color turns into brown-yellow, take it out quickly and cool down;

[0023] (2) Add 80 mL of ionic liquid ethanol solution to the croton processed product in step (1), mix well, and the ionic liquid is BmimCF 3 SO 3 , with a concentration of 0.3mol / L, reacted at 50°C for 10h to obtain a mixed solution;

[0024] (3) Microfilter the mixture in step (2), collect the filtrate, and remove ethanol;

[0025] (4) The filtrate is separated by column chromatography, 200-300 mesh silica gel column, the eluent is petroleum ether and acetone, the volume ratio of the two is 1:1-10:1, concentrated under red...

Embodiment 2

[0027] A method utilizing ionic liquid to extract fatty oil in croton comprises the following steps:

[0028] (1) Peel the croton seeds, take 12g of the seed kernels, process them, and crush them to obtain processed crotons; the processing method is as follows: heat an empty pan, stir-fry the croton kernels, and fry until the cross-section of the croton kernels is When the yellow-white color turns into brown-yellow, take it out quickly and cool down;

[0029] (2) Add 90 mL of ionic liquid ethanol solution to the croton processed product in step (1), mix well, and the ionic liquid is BmimPF 6 , with a concentration of 0.4mol / L, reacted at 55°C for 8 hours to obtain a mixed solution;

[0030] (3) Microfilter the mixture in step (2), collect the filtrate, and remove ethanol;

[0031] (4) The filtrate is separated by column chromatography, 200-300 mesh silica gel column, the eluent is petroleum ether and acetone, the volume ratio of the two is 1:1-10:1, concentrated under reduce...

Embodiment 3

[0033] A method utilizing ionic liquid to extract fatty oil in croton comprises the following steps:

[0034] (1) Peel the croton seeds, take 15 g of the seed kernels, process them, and crush them to obtain the processed croton products; When the yellow-white color turns into brown-yellow, take it out quickly and cool down;

[0035] (2) Add 100 mL of ionic liquid ethanol solution to the croton processed product in step (1), mix well, and the ionic liquid is BmimSbF 6 , with a concentration of 0.42mol / L, reacted at 60°C for 7 hours to obtain a mixed solution;

[0036] (3) Microfilter the mixture in step (2), collect the filtrate, and remove ethanol;

[0037] (4) The filtrate was separated by column chromatography, concentrated under reduced pressure, and dried in vacuo to obtain 4.3 g of fatty oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com