A 3D chip stacked interconnect material containing eu and nano-au

A technology of chip stacking and interconnection materials, applied in electrical components, circuits, electrical solid devices, etc., can solve the problems of limiting the application of three-dimensional packaging chip stacking, low reliability, etc., to meet the requirements of high reliability, high service life, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The composition of a 3D chip stacked interconnect material containing Eu and nano-Au is: 0.5% of rare earth element Eu, 5% of nano-Au particles, and the balance is In.

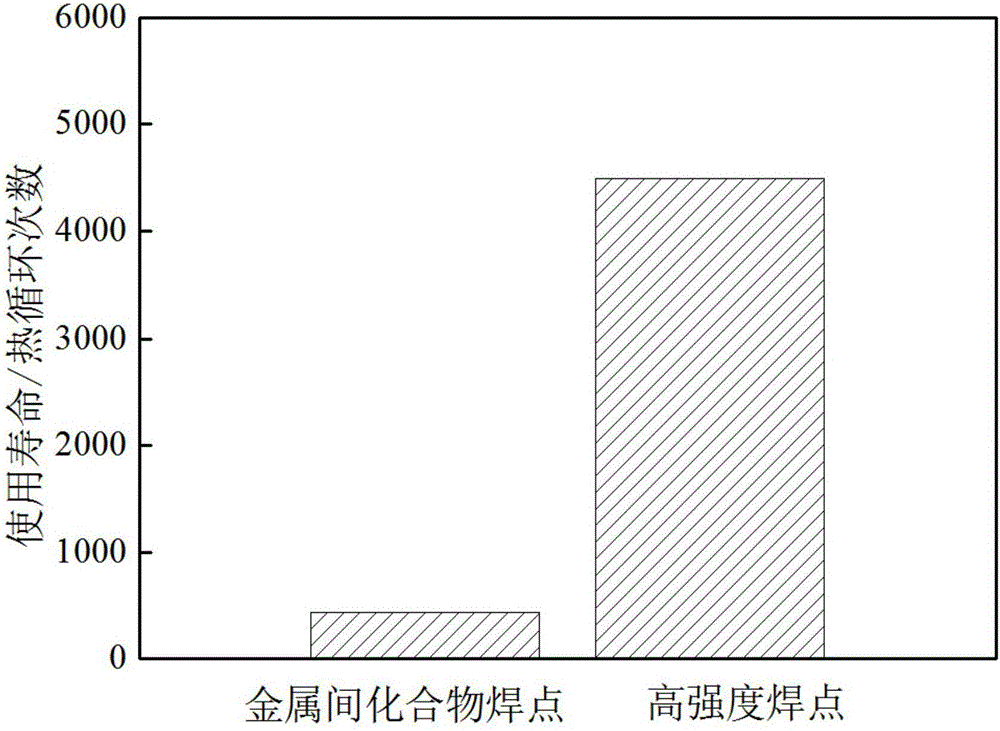

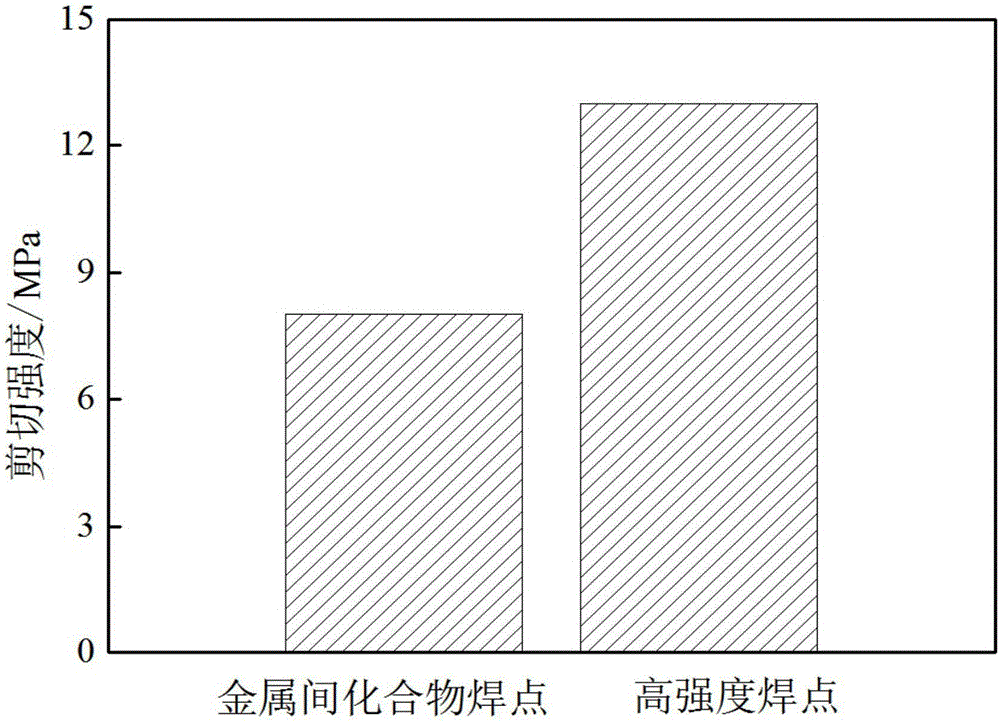

[0019] The service life of the high-strength solder joints formed after bonding (170°C, 5MPa) is about 3500 thermal cycles (considering the experimental error), and the paste interconnection material has excellent solderability.

Embodiment 2

[0021] A 3D chip-stacked interconnect material containing Eu and nano-Au is composed of: 0.01% of rare earth element Eu, 8% of nano-Au particles, and the balance of In.

[0022] The service life of the high-strength solder joints formed after bonding (26°C, 5MPa) is about 3750 thermal cycles (considering the experimental error), and the paste interconnection material has excellent solderability.

Embodiment 3

[0024] A 3D chip-stacked interconnect material containing Eu and nano-Au is composed of: 0.5% of rare earth element Eu, 8% of nano-Au particles, and the balance is In.

[0025] The service life of the high-strength solder joints formed after bonding (260°C, 10MPa) is about 4490 thermal cycles (considering the experimental error), and the paste interconnection material has excellent solderability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com