Method based on polyethyleneimine-silver ion chelate for preparing antibacterial plush product

A polyethyleneimine, chelate technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of natural antibacterial agents staying at the empirical level and the research on antibacterial mechanism is not clear, and achieve long-term antibacterial properties, avoid Effects of pollution, strong chelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

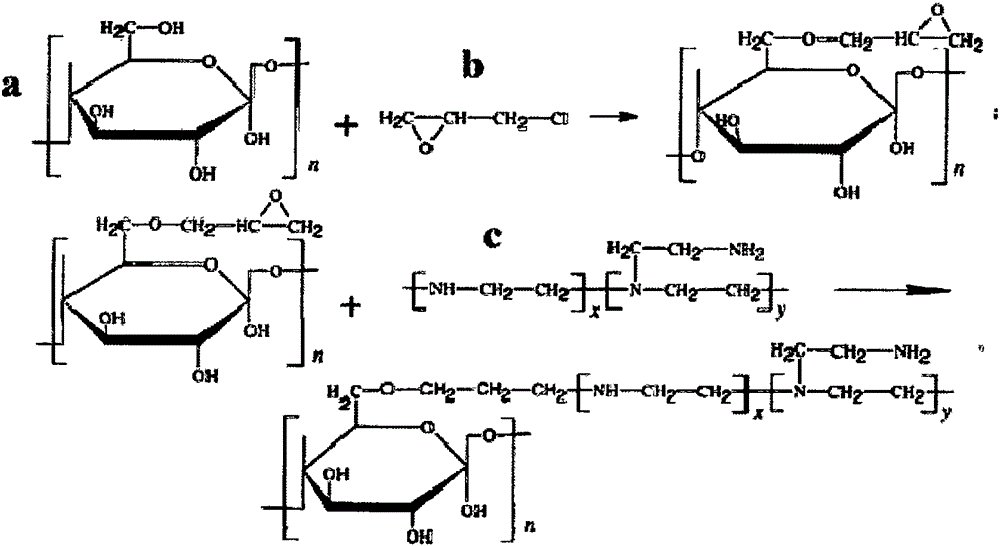

Method used

Image

Examples

Embodiment 1

[0019] An antibacterial treatment process for plush products, comprising the following steps: (1) configuring an antibacterial treatment agent; (2) epoxidizing the plush products; (3) treating the plush products after step (2) The surface grafted polyethyleneimine (polyethyleneimine); (4) through the step (3) the plush product grafted with polyethyleneimine and the nano-silver particle chelation in the antibacterial treatment agent; (5) The plush product treated in step (4) is washed three times with deionized water to remove the antibacterial treatment agent floating on the surface. After cleaning, it is placed in a blast oven at 60° C. to dry to obtain the plush product with antibacterial properties.

[0020] The antibacterial treatment agent preparation process described in step (1) is: the sodium hydroxide of 5 parts by weight is dissolved in 92 parts of water, after fully dissolving, add 3 parts by weight, the silver nitrate that size is 25nm, fully mix 24h under stirring ...

Embodiment 2

[0027] An antibacterial treatment process for plush products, comprising the following steps: (1) configuring an antibacterial treatment agent; (2) epoxidizing the plush products; (3) treating the plush products after step (2) The surface grafted polyethyleneimine (polyethyleneimine); (4) through the step (3) the plush product grafted with polyethyleneimine and the nano-silver particle chelation in the antibacterial treatment agent; (5) The plush product treated in step (4) is washed three times with deionized water to remove the antibacterial treatment agent floating on the surface. After cleaning, it is placed in a blast oven at 60° C. to dry to obtain the plush product with antibacterial properties.

[0028] The preparation process of the antibacterial treatment agent described in step (1) is: the sodium hydroxide of 3.5 parts by weight is dissolved in 87.5 parts of water, after fully dissolving, add 9 parts by weight of silver carbonate with a size of 40nm, fully mix for 18...

Embodiment 3

[0035] An antibacterial treatment process for plush products, comprising the following steps: (1) configuring an antibacterial treatment agent; (2) epoxidizing the plush products; (3) treating the plush products after step (2) The surface grafted polyethyleneimine (polyethyleneimine); (4) through the step (3) the plush product grafted with polyethyleneimine and the nano-silver particle chelation in the antibacterial treatment agent; (5) The plush product treated in step (4) is washed three times with deionized water to remove the antibacterial treatment agent floating on the surface. After cleaning, it is placed in a blast oven at 60° C. to dry to obtain the plush product with antibacterial properties.

[0036] The antibacterial treatment agent preparation process described in step (1) is: the sodium hydroxide of 5 parts by weight is dissolved in 80 parts of water, after fully dissolving, add 15 parts by weight, the silver chloride that size is 10nm, fully mix under stirring 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com