Method for correcting well shaft pressure in real time

A wellbore pressure and real-time correction technology, which is applied in the field of petroleum drilling engineering, can solve problems such as large error in results, complicated calculation process, and unsatisfactory calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

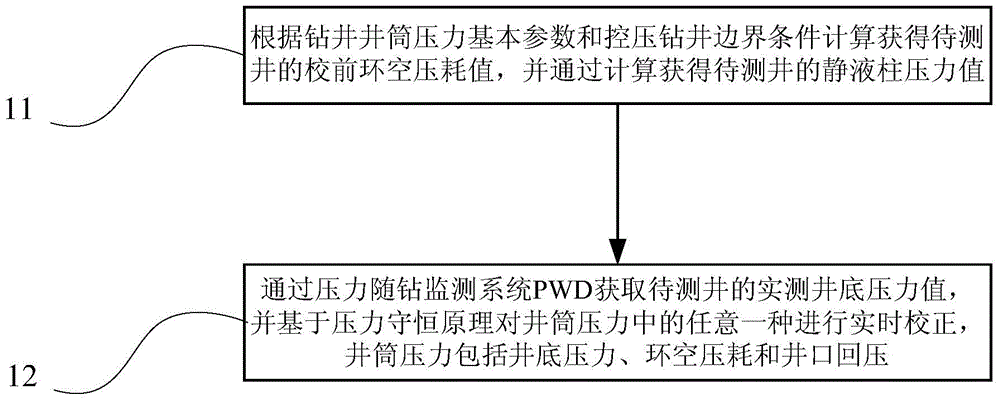

Examples

Embodiment Construction

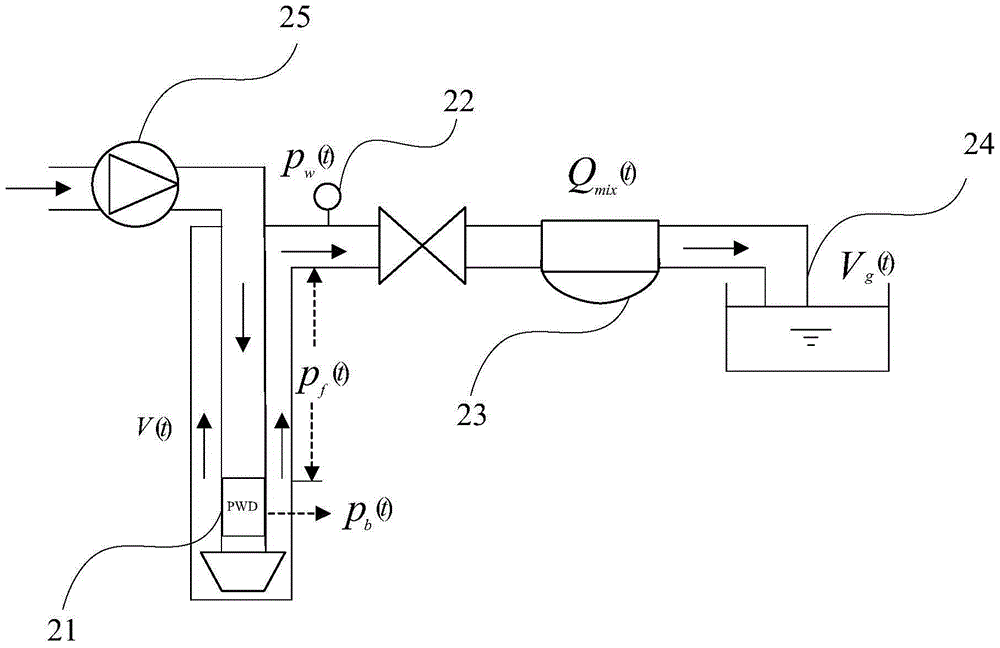

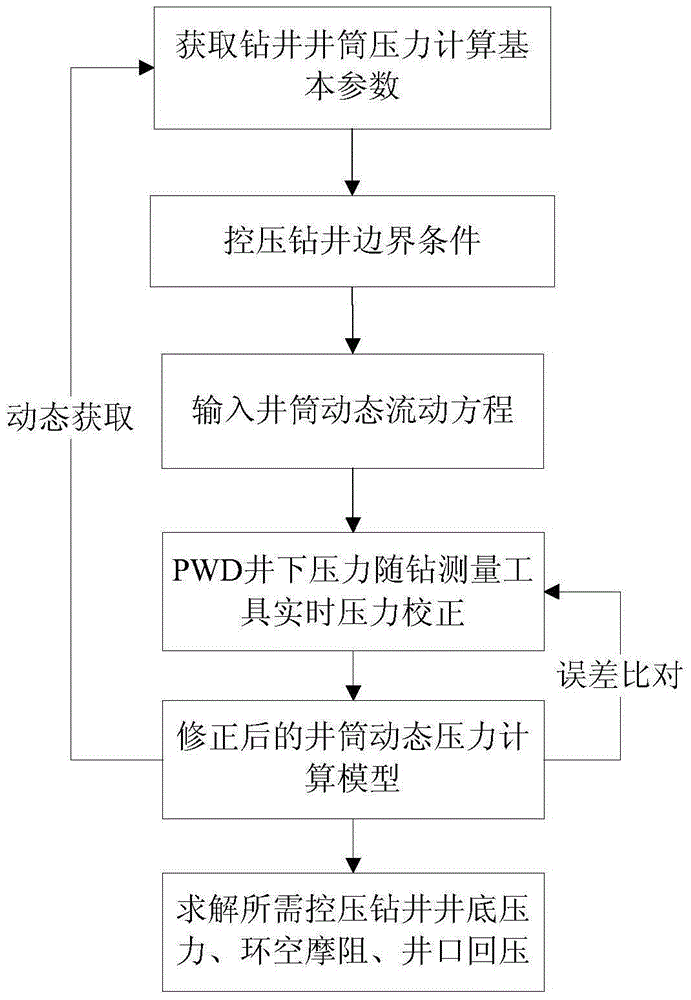

[0052]In the prior art in this field, the pressure propagation of the multiphase flow is more complicated due to the instability of the pressure wave and the density wave, so it is not easy to perform managed pressure drilling. However, in the process of MPD operations, currently only multiphase fluids with a gas content of no more than 15% can be processed safely for MPD drilling. This is also the essence of the pressure control technology adopted by the fine MPD system for throttling with automatic throttle valves. Determining: In addition, the throttle valve cannot guarantee the stability of the throttle pressure under the condition that the gas phase content is too high. Therefore, it can be considered that the purpose of managed pressure drilling is mainly to perform micro-overbalanced pressure control drilling. Therefore, the present invention establishes the wellbore pressure suitable for managed pressure drilling based on the theory of gas-liquid two-phase flow in the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com