Hydraulic structure seepage property distributed optical fiber sensing integrated system and method

A technology for hydraulic structures and distributed optical fibers, which is used in fluid tightness testing, application of light to test fluid tightness, optics, etc. The effect of improving calibration accuracy and layout efficiency, high spatial resolution, and high running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

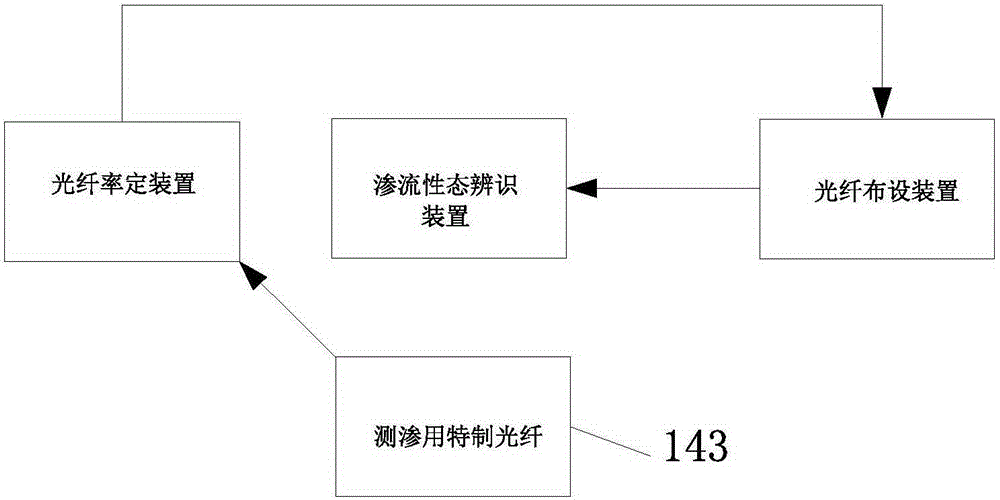

[0035] Such as Figure 1 to Figure 11 As shown, the distributed optical fiber perception integrated system for seepage behavior of hydraulic structures of the present invention includes a special optical fiber 143 for seepage measurement, an optical fiber rating device, an optical fiber laying device, and a seepage behavior identification device. After on-site calibration with the special optical fiber 143 for seepage, the laying and testing of the special optical fiber 143 for seepage measurement is carried out with the help of the optical fiber laying device. After the test is successful, it is connected to the seepage behavior identification device for information collection, processing and analysis.

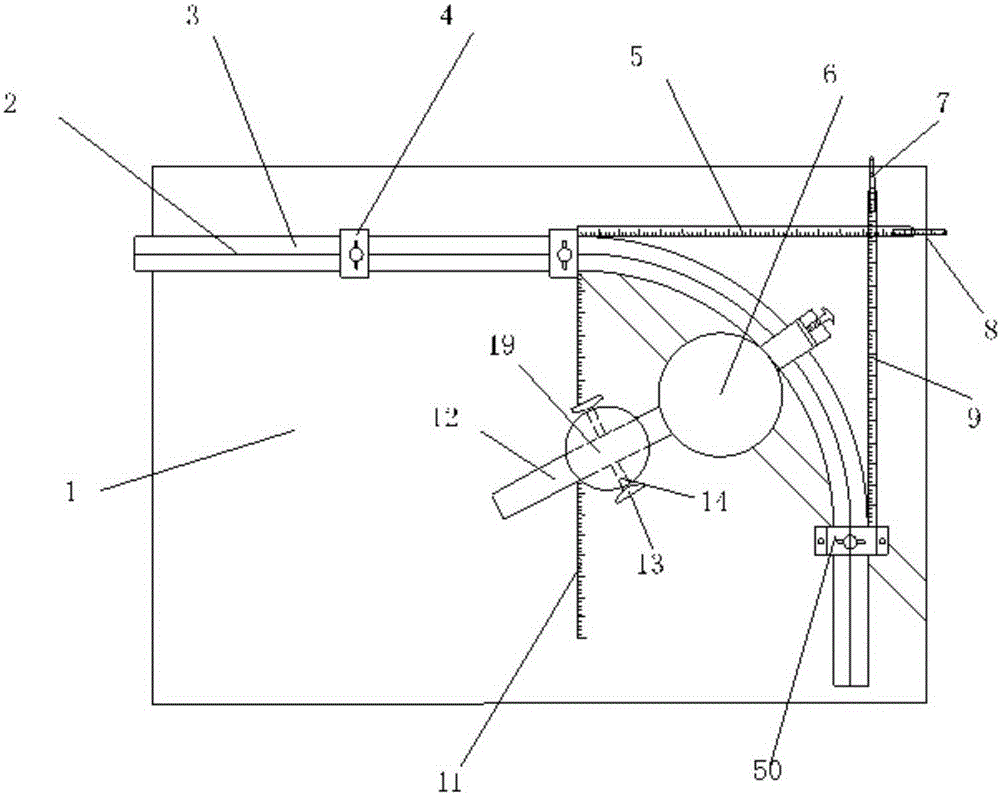

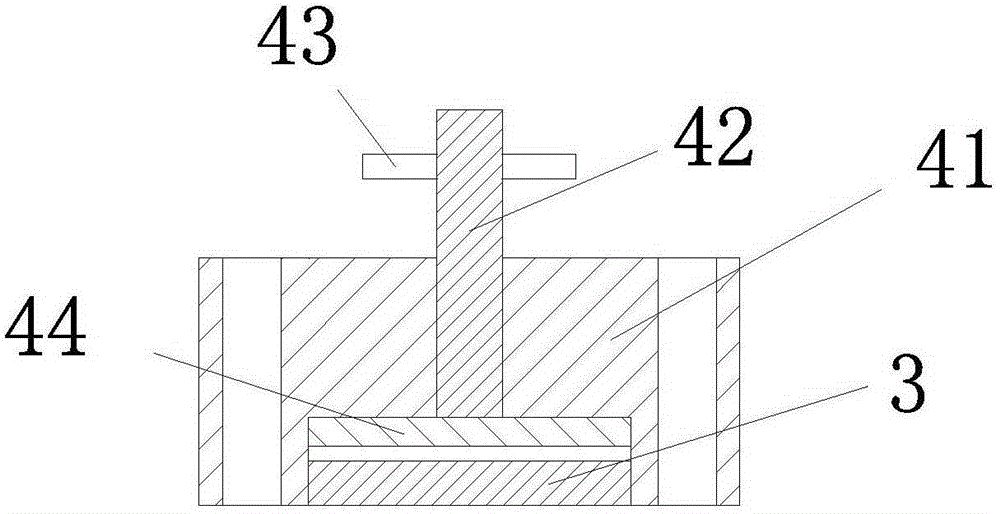

[0036] The optical fiber laying device includes a bending table 1 and a guideway 3 located on the bending table 1, the guideway 3 is made of flexible plastic, a guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com