Hybrid wavelength laser wire-stripping method and wire-stripping apparatus of wire sheaths

A technology of mixing wavelengths and wire sheaths, applied in the field of wire stripping devices, can solve the problems of high cost, low efficiency, unfavorable flow operation, etc., and achieve the effects of convenient operation, improved efficiency and good wire stripping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

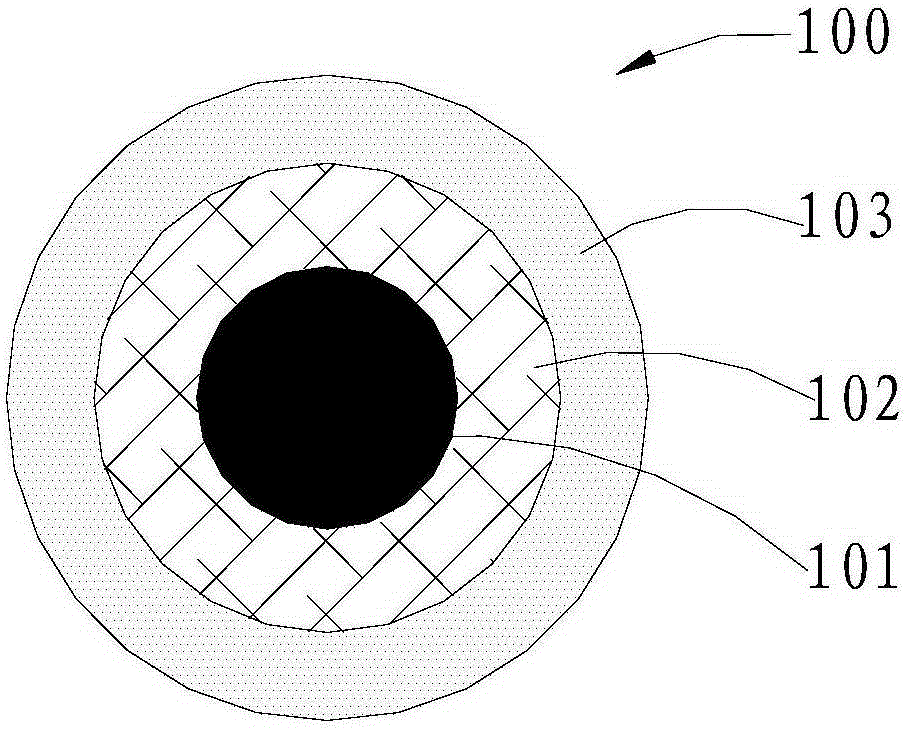

[0044] see figure 1 As shown, the wire 100 to be stripped includes a metal core 101 , a metal braid 102 wrapped around the metal core 101 from inside to outside, and an insulating outer layer 103 .

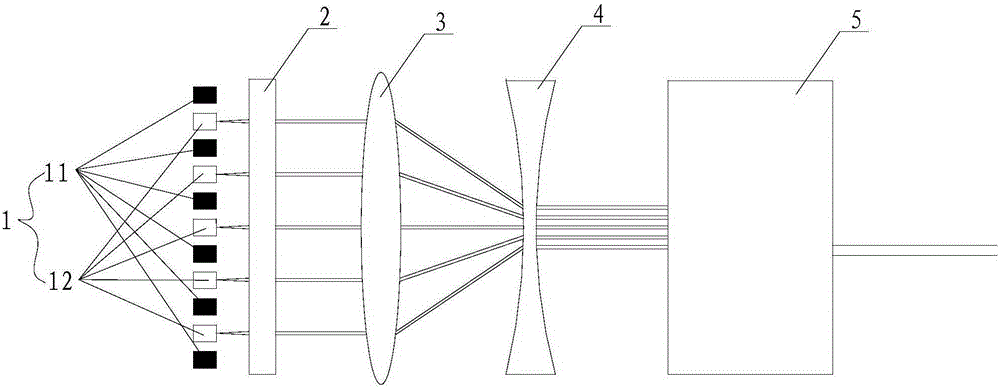

[0045] see figure 2 As shown, the mixed-wavelength laser stripping device for the wire sheath includes:

[0046] Light source 1: The light source includes two groups of laser diodes, which are respectively a plurality of first laser diodes 11 that can generate a wavelength of λ1 and are correspondingly used for cutting the insulating outer layer 103, and a plurality of first laser diodes 11 that can generate a wavelength of λ2 and are correspondingly used for cutting The second laser diode 12 of the metal braided layer 102 arranges all the first laser diodes 11 and the second laser diodes 12 at intervals in turn to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com