Raw bamboo slitting equipment capable of achieving quick removal of bamboo joint

A slub and original bamboo technology is applied in the field of original bamboo slitting equipment for rapidly removing slub, which can solve the problems of inability to remove the slub part well, reduce the processing efficiency of the original bamboo, increase the manufacturing cost of the original bamboo, and the like. The effect of increasing the striping effect, improving the striping effect, and improving the striping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

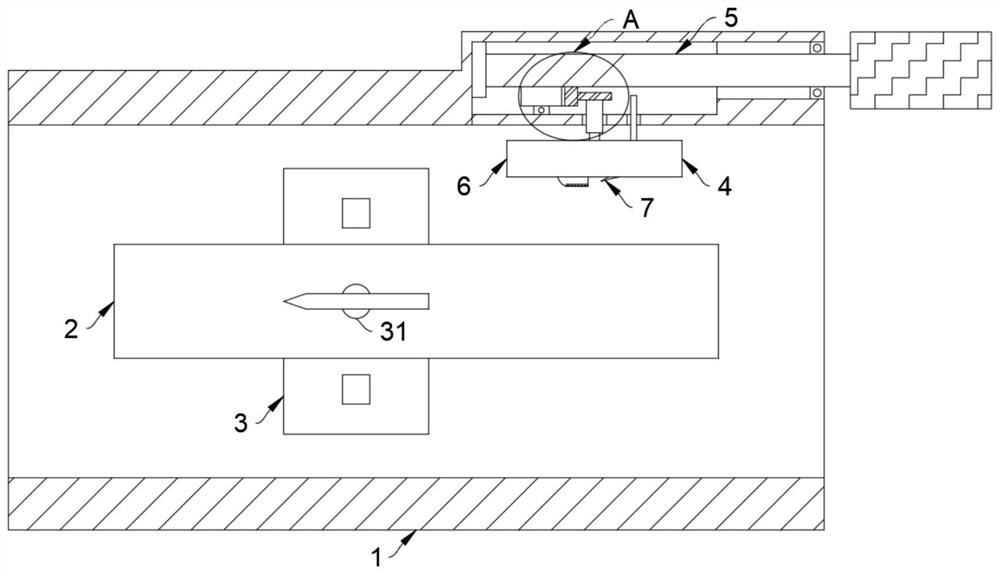

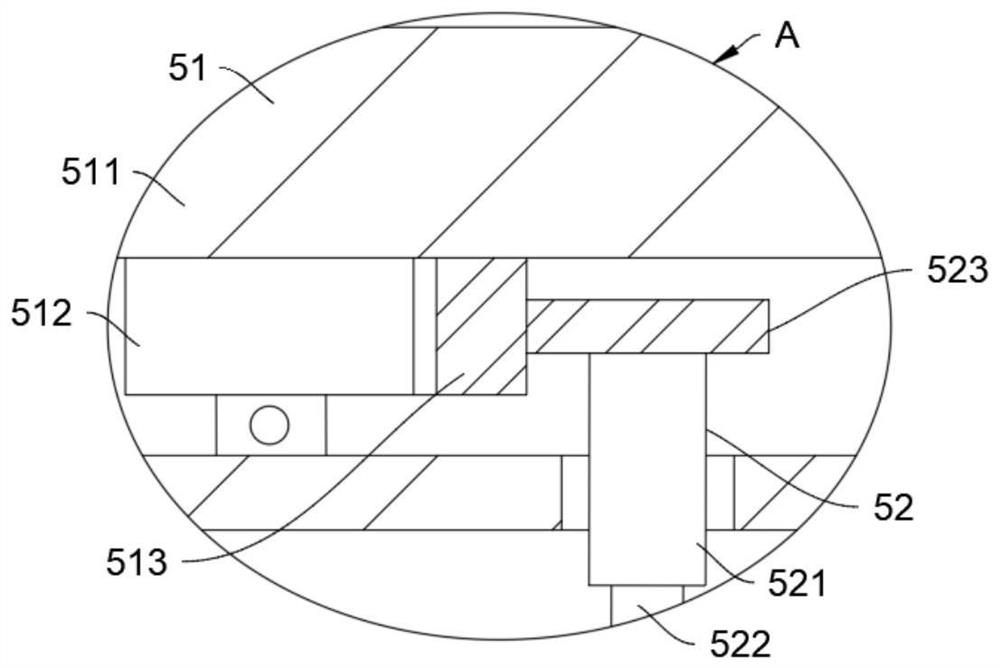

[0025] Such as Figure 1-4 As shown, a raw bamboo slitting device for quickly removing bamboo knots includes a cylinder body 1, and the cylinder body 1 is fixedly connected with a cutting shaft 2. It should be noted that the cylinder body 1 includes a feed port and a discharge port. 1 and the cutting shaft 2 are coaxially fixedly connected to ensure the uniformity of the original bamboo cutting process.

[0026] Concrete fixed connection mode: the cutting shaft 2 is provided with multiple sets of cutting blades 3, the cutting blades 3 include a support blade 34 and a side blade 35, the thickness of the support blade 34 near the end of the cylinder body 1 is greater than the thickness of the side blade 35, the support blade 34 While playing the role of cutting and slitting, the cutting shaft 2 and the cylinder body 1 are fixed by welding to improve the stability of the cutting and slitting device.

[0027] More specifically, the cutting blade 3 is symmetrically provided with a...

Embodiment 2

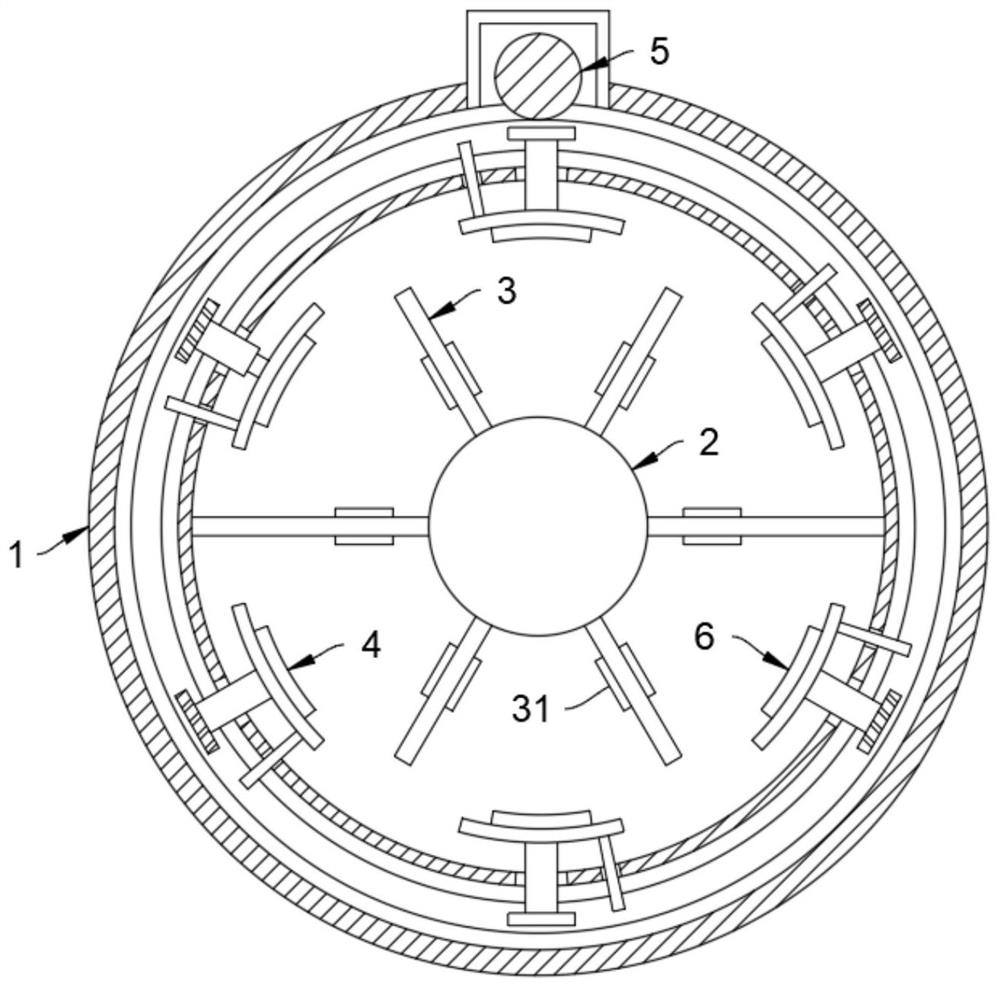

[0038] Such as Figure 5-7 Shown, the difference between this embodiment and the embodiment is:

[0039]One group of cutting blades 3 is rotatably connected with friction wheel 32, and friction wheel 32 is rotatably connected with drill bit 8 through bevel gear 33. One end is fixedly connected with a rotating shaft, and the end of the rotating shaft close to the cutting shaft 2 is provided with a bevel gear 33, the bevel gear 33 includes a driving bevel gear and a driven bevel gear, and the cutting shaft 2 is provided with a cavity for the rotation and transmission of the bevel gear 33 .

[0040] Specifically, the drill bit 8 is rotatably connected to the end of the cutting shaft 2 away from the clamping mechanism 6. It should be noted that the drill bit 8 is driven by the driven bevel gear to rotate, so that the raw bamboo is rotated by the friction wheel 32 during cutting. The drill bit 8 is driven to drill holes in the inner section of the bamboo joint, so as to improve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com