The production process of the positioning rib of the stator core of the hydroelectric generator

A hydraulic generator and production process technology, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of low processing efficiency, large material loss, and high equipment requirements, so as to improve material utilization, improve processing efficiency, and reduce processing difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

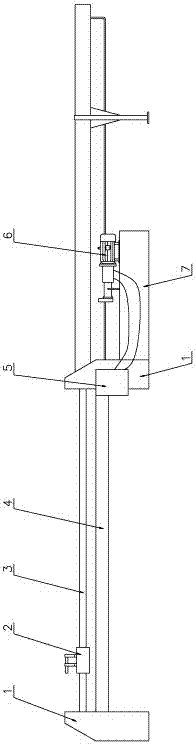

Image

Examples

Embodiment Construction

[0034] see Figure 1-Figure 10 , the present invention is a kind of hydraulic generator stator iron core positioning rib production process, comprising the following steps:

[0035] a. Put the raw materials into the warehouse for appearance, size and chemical composition inspection. The qualified raw materials are cut into individual workpieces according to the production requirements, and one end of each workpiece is fully welded on the clamp handle by the electric welding machine;

[0036] b. Annealing treatment: Arrange the workpieces neatly in order, and stack several pieces in a row for at least 5 layers. The gap between each layer is guaranteed to be 6-10 mm, preferably 8 mm, and it is tied tightly with iron wires and sent to the trolley furnace for annealing treatment. Set the annealing temperature at 710-740°C and keep it warm for 4-5 hours, preferably 710°C and keep it warm for 5 hours, and then let it cool naturally;

[0037] c. Phosphating saponification treatment:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com