Static eliminator

A static eliminator and discharge needle technology, applied in the direction of static electricity, electrical components, etc., can solve the problems of cumbersome troubles, reduced efficiency of static electricity elimination, uneven distribution of ions, etc., and achieve the effects of improving the level of automation, simplifying the use procedure, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

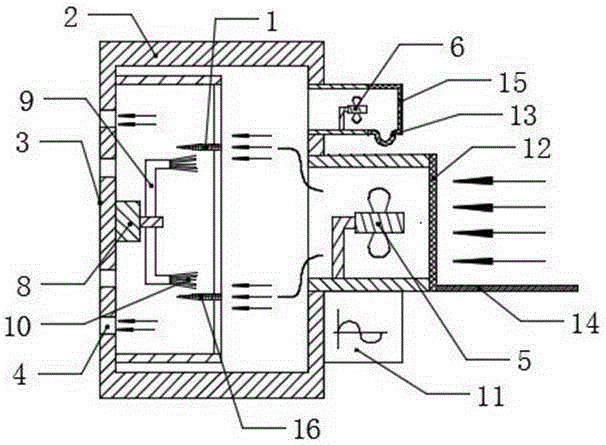

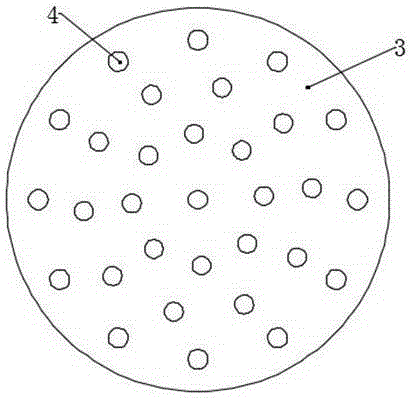

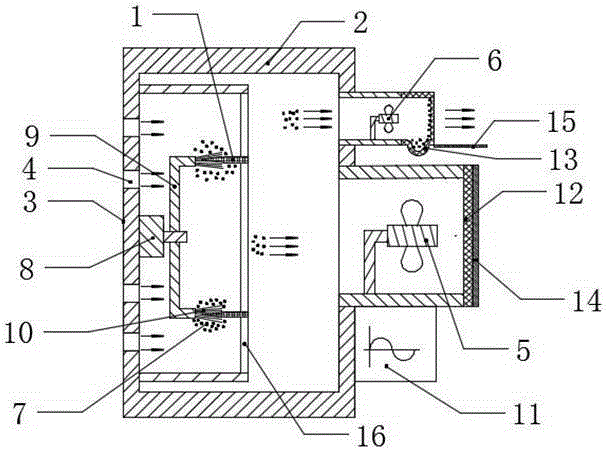

[0024] like figure 1 As shown, the static eliminator includes: a discharge needle 1, which ionizes the air to generate an ionized gas through corona discharge; a housing 2, whose front face 3 has a plurality of small holes 4 for the ionized gas to pass through; a blower fan 5, Located at the rear of the housing 2, it is used to generate air flow to allow the ionized gas to flow to the outside of the housing 2; the rotating device 8 is used to rotate the rotating arm 9 installed on the rotating device 8, so that the The brush 10 at the end of 9 cleans the dust 7 on the discharge needle 1; the dust removal fan 6 is located at the rear of the casing 2, and is used to generate air flow to discharge the dust 7 generated by the brush 10 cleaning the discharge needle 1 to the outside of the casing 2; The supply device 11 is used to supply power to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com