Helium-neon laser treatment device and manufacturing method thereof

A helium-neon laser and treatment device technology, which is applied in the field of laser medical equipment, can solve the problems of laser tube output power variation, damage, and easy falling off, and achieve the effects of reducing intracavity loss, avoiding pollution, and increasing laser output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

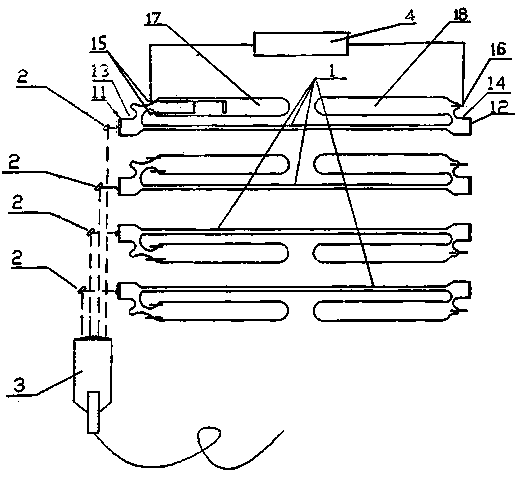

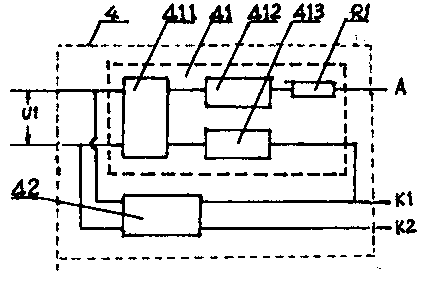

[0059] The preparation method of the helium-neon laser treatment device of the present invention, the first step, respectively prepare the inner cavity flat helium-neon laser tube 1, the circuit board of the laser power supply 4 and the treatment device casing;

[0060] In the second step, the circuit boards of the inner cavity flat helium-neon laser tube 1 and the laser power supply 4 are installed on the corresponding parts of the treatment device casing, and the circuit boards of the inner cavity flat helium-neon laser tube 1 and the laser power supply 4 are connected with wires;

[0061] The third step is to turn on the laser power supply 4 and adjust the plane mirrors 2 so that the laser light reflected by each plane mirror 2 is parallel to each other and enters the fiber coupler 3;

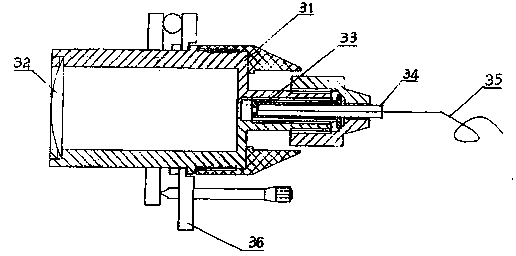

[0062] The fourth step is to insert the optical fiber plug 34 connected with the optical fiber 35 into the optical fiber positioning socket 33, insert the end of the optical fiber 35 into the...

Embodiment 1

[0079] Embodiment 1, with 4 1 meter long inner cavity flat discharge tube he-neon laser tubes, its output power is about 60 milliwatts, after adjustment, the laser power above 180 milliwatts can be obtained at the optical fiber end of the treatment machine.

Embodiment 2

[0080] Embodiment 2, with 4 1.5 meters long half-cavity flat discharge tube He-Ne laser tubes, its output power is about 135 milliwatts, after adjustment, can obtain the laser power above 400 milliwatts at the optical fiber end of the treatment machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com