A roasting process for reducing starch and increasing flavor of flue-cured tobacco

A baking process and starch technology, applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of difficulty in filling cigarettes, high starch content in tobacco leaves, and high proportion of variegated tobacco in tobacco leaves, so as to improve the appearance quality and internal quality, reduce the Starch content of tobacco leaves and the effect of reducing the loss of aroma substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Tobacco leaves 9-11 of Yunyan 87 tobacco leaves in a certain production area in Hubei Province are placed on conventional hanging rod racks, and the baking process of the present invention is adopted, and the following specific operations are carried out in an air-flow ascending intensive curing barn:

[0023] (1) The intensive curing room is equipped with flue-cured tobacco controllers, fans, cold air doors, and temperature and humidity probes; for the inspection of the baking equipment before loading tobacco, the temperature and humidity probes are installed in the lower shed of the tobacco loading room and the probes are hung at the tip of the tobacco leaves in the lower shed, and the probes in the upper shed are hung At the tip of the tobacco leaf in the upper shed, it is controlled according to the temperature and humidity probe in the lower shed during baking; the flue-cured tobacco controller controls the heating and dehumidification automatically by sen...

Embodiment 2

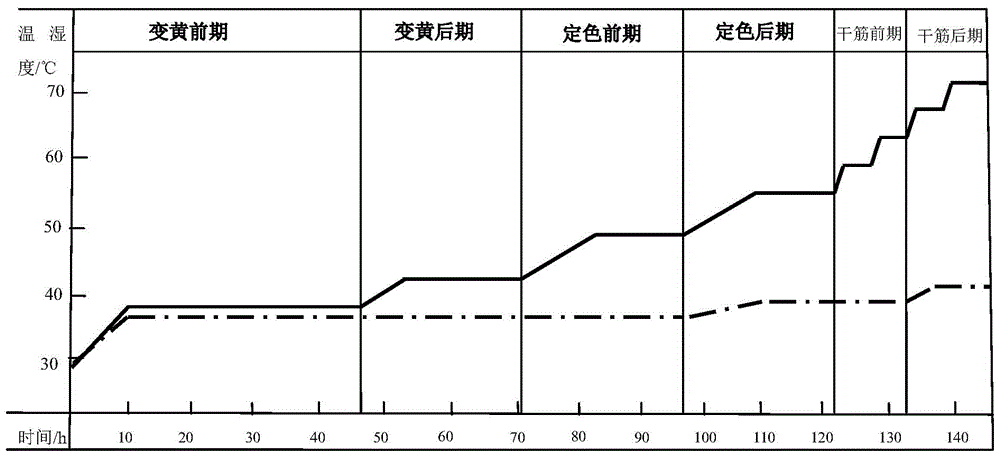

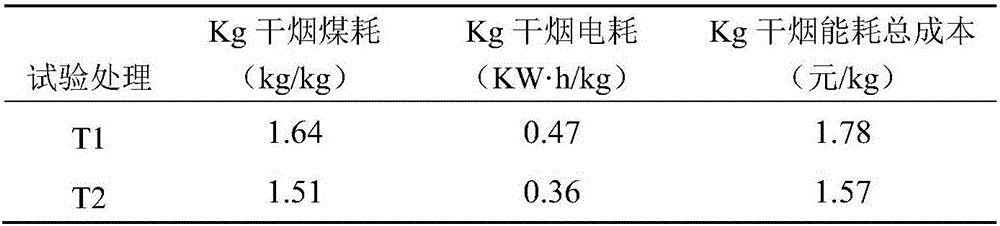

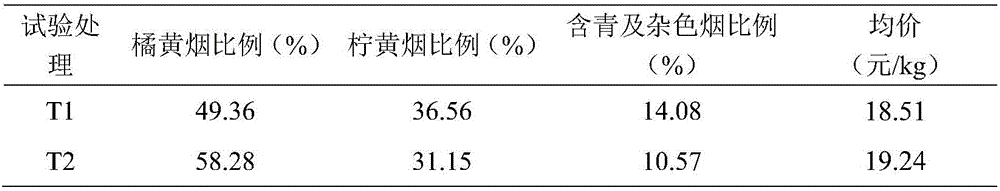

[0030] Embodiment 2 For the central tobacco leaves of Yunyan 87 in a certain producing area in Hubei Province, the following two baking processes are adopted: T1 is a three-stage baking process (existing conventional process) for hanging rod baking, and T2 adopts the process described in the present invention. (Flue-cured tobacco reducing starch and flavoring baking process), according to the attached figure 1 The curing curve is set, the temperature stabilization time of each stage is adjusted in real time according to the yellowing and drying degree of the tobacco leaves, the energy consumption statistics of the curing are carried out, and the economic properties, appearance quality, chemical composition and sensory quality of the tobacco leaves are compared. The results are shown in Table 1-4.

[0031] Table 1 Comparison of energy consumption of different baking processes

[0032]

[0033] Note: Coal is 800 yuan per ton; electricity price is 1.0 yuan / KW·h.

[0034] Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com