Method for improving utilization ratio of starch in corn hull

A corn husk and utilization rate technology, applied in the field of corn deep processing, can solve the problems of insufficient utilization, waste, starch residue, etc., and achieve the effect of sufficient hydrolysis degree, low starch residue, and low starch content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

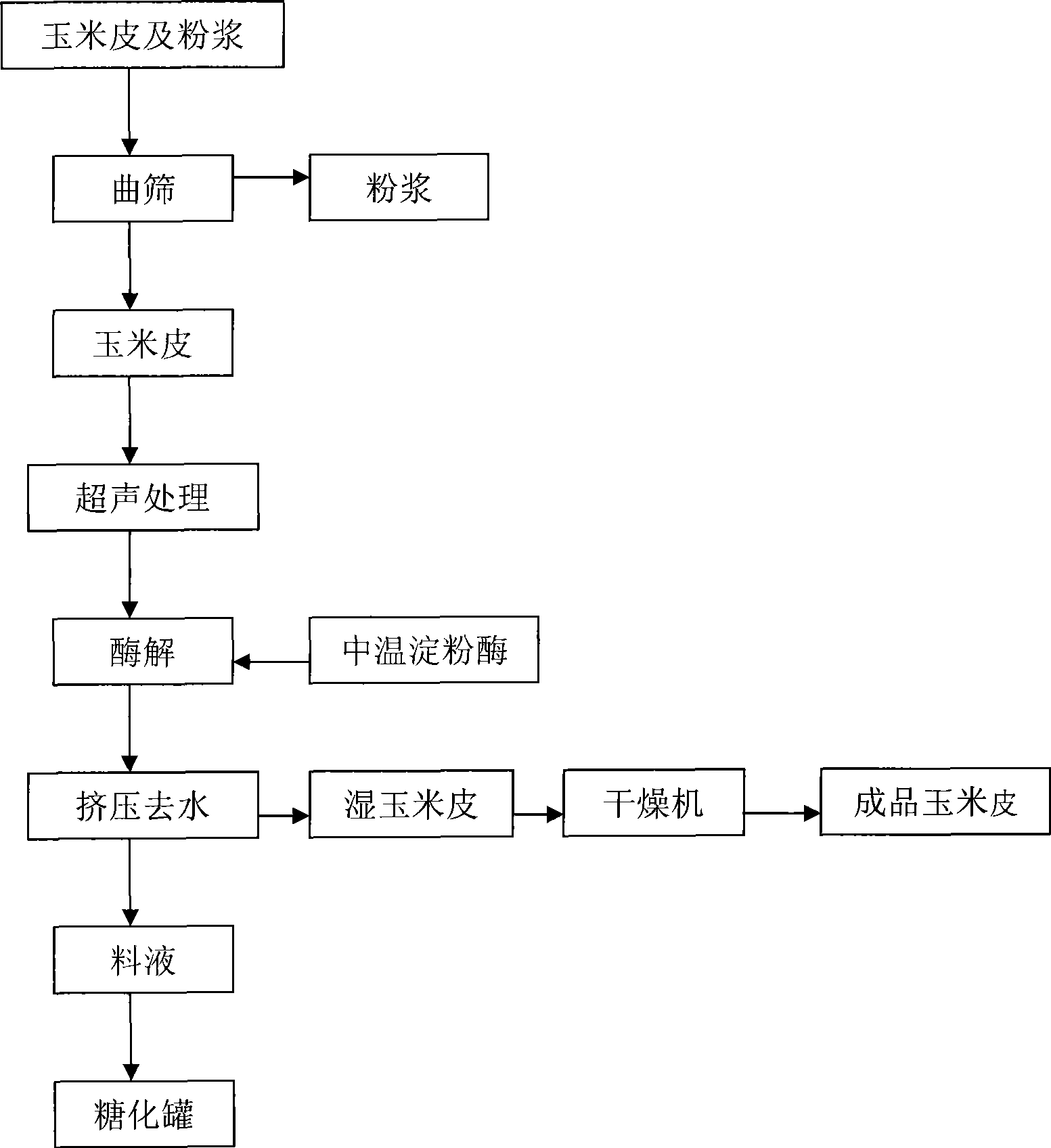

Image

Examples

Embodiment 1

[0020] Embodiment 1: a kind of method that improves the utilization rate of starch in corn husk, is raw material with the corn husk that obtains after washing and separating through high-pressure curved sieve in the corn deep processing process, and steps are as follows:

[0021] (1) Add corn husks to water at a ratio of 1:10, and at a temperature of 25° C., use a power of 5 kW for ultrasonic treatment for 20 minutes to obtain corn husk slurry;

[0022] (2) Adjust the pH value of the corn husk slurry prepared in step (1) to 5.5 with sodium carbonate, and then add a medium-temperature amylase for enzymatic hydrolysis. The action conditions of the medium-temperature amylase are: time 15min, temperature 65°C, enzyme concentration in the system 0.02ml / L, substrate concentration: 100g / L, to obtain enzymatic hydrolyzate of corn hulls;

[0023] (3) separating the corn bran and the feed liquid in the corn bran enzymatic hydrolysis solution prepared in step (2). The moisture content o...

Embodiment 2

[0024] Embodiment 2: a kind of method that improves the utilization rate of starch in the corn bran, is raw material with the corn bran that obtains after washing and separating through the high-pressure curved sieve in the deep processing of corn, and the steps are as follows:

[0025] (1) Add corn husks into water at a ratio of 1:8, and at a temperature of 30° C., use a power of 7 kW for ultrasonic treatment for 15 minutes to obtain corn husk slurry;

[0026] (2) Adjust the pH value of the corn husk slurry prepared in step (1) to 6.5 with sodium hydroxide, and then add mid-temperature amylase for enzymatic hydrolysis. The action conditions of the mid-temperature amylase are: time 20min, temperature 70°C, The concentration is 0.03ml / L, the substrate concentration is: 120g / L, and the enzymatic hydrolyzate of corn hulls is obtained;

[0027] (3) the corn bran in the corn bran enzymatic hydrolysis solution that step (2) is made is separated from feed liquid; The moisture of corn...

Embodiment 3

[0028] Embodiment 3: a kind of method that improves the utilization rate of starch in corn husk, is raw material with the corn husk that obtains after washing and separating through high-pressure curved sieve in the corn deep processing process, and steps are as follows:

[0029] (1) Add corn husks into water at a ratio of 1:6, and at a temperature of 35° C., use a power of 9 kW for ultrasonic treatment for 11 minutes to obtain corn husk slurry;

[0030] (2) Adjust the pH value of the corn husk slurry prepared in step (1) to 7.0 with sodium carbonate, and then add a medium-temperature amylase for enzymatic hydrolysis. The conditions for the action of the medium-temperature amylase are: time 25min, temperature 75°C, and enzyme concentration in the system 0.05ml / L, and substrate concentration: 150g / L, to obtain enzymatic hydrolyzate of corn hulls;

[0031] (3) the corn bran in the corn bran enzymatic hydrolysis liquid that step (2) is made is separated from feed liquid; The mois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com