Process capable of obviously improving room-temperature forming property of AZ31 magnesium alloy plate

A formability, magnesium alloy technology, applied in the field of high-performance magnesium alloy plate preparation, to achieve the effect of easy processing, simple mold and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

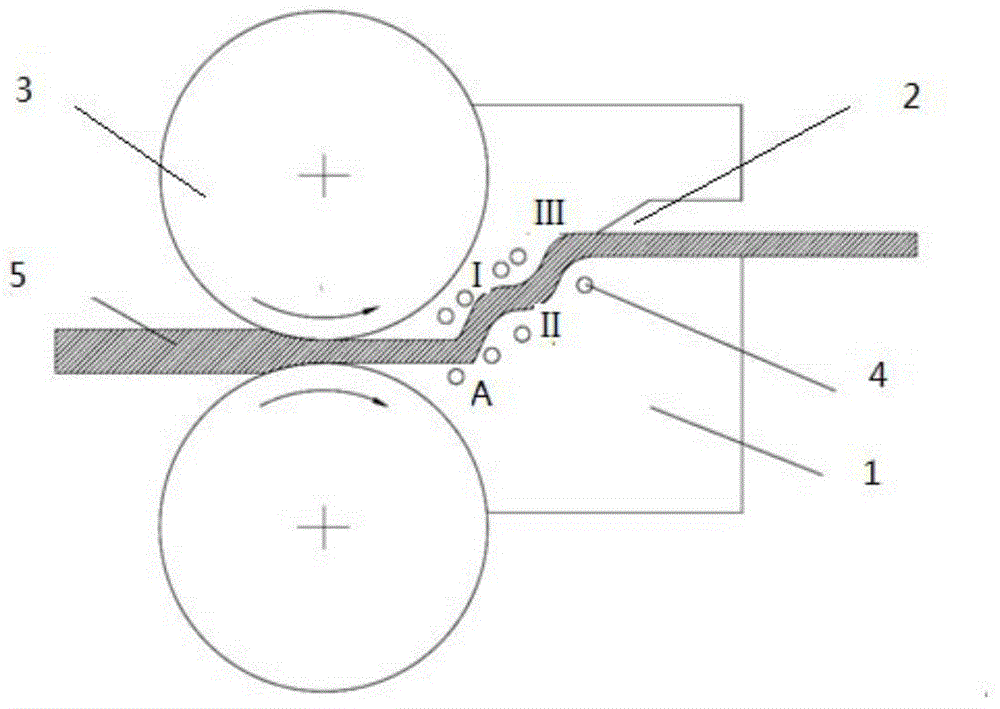

[0025] The details of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] Such as image 3 Shown, the technology that the present invention proposes is rolling-shearing-continuous bending composite technology (abbreviation RSCB technology), adopts this technology to prepare the specific process of high-performance AZ31 wrought magnesium alloy sheet material as follows:

[0027] First, the AZ31 magnesium alloy sheet is rolled from 4.3mm to 1.5mm thick in 7 passes at 500°C, and then rolled at 550°C to obtain a 1.26mm thick sheet for the final rolling-shearing- Continuous bending deformation.

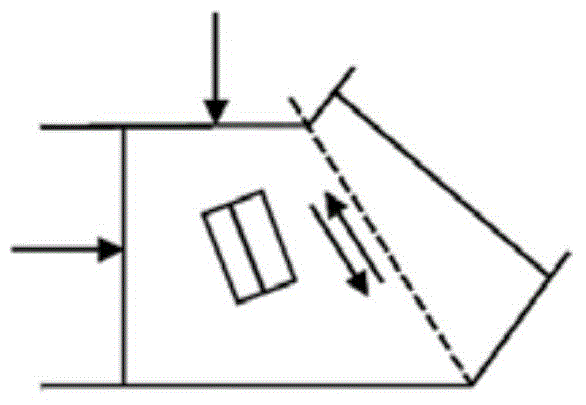

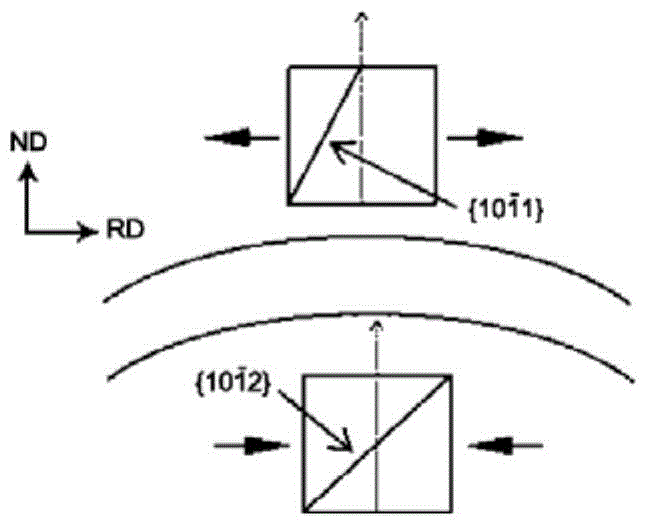

[0028] Then the magnesium alloy plate is deformed by hot rolling through the roll, and the friction force generated by the rolling deformation is used to provide power, so that the plate continuously passes through a mold with equal rolling channel height and continuous bending for shearing and continuous multi-pass bending to achi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com