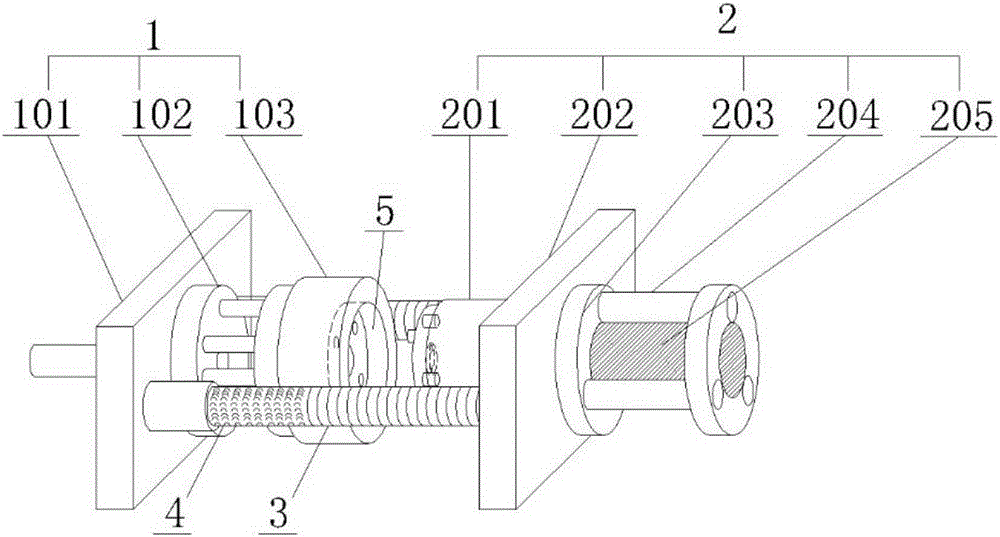

Rapid mold for novel impeller bottom cover of vertical pump

A technology of vertical pumps and forming dies, applied in forming tools, metal processing equipment, manufacturing tools, etc., to achieve the effects of low noise, long service life and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

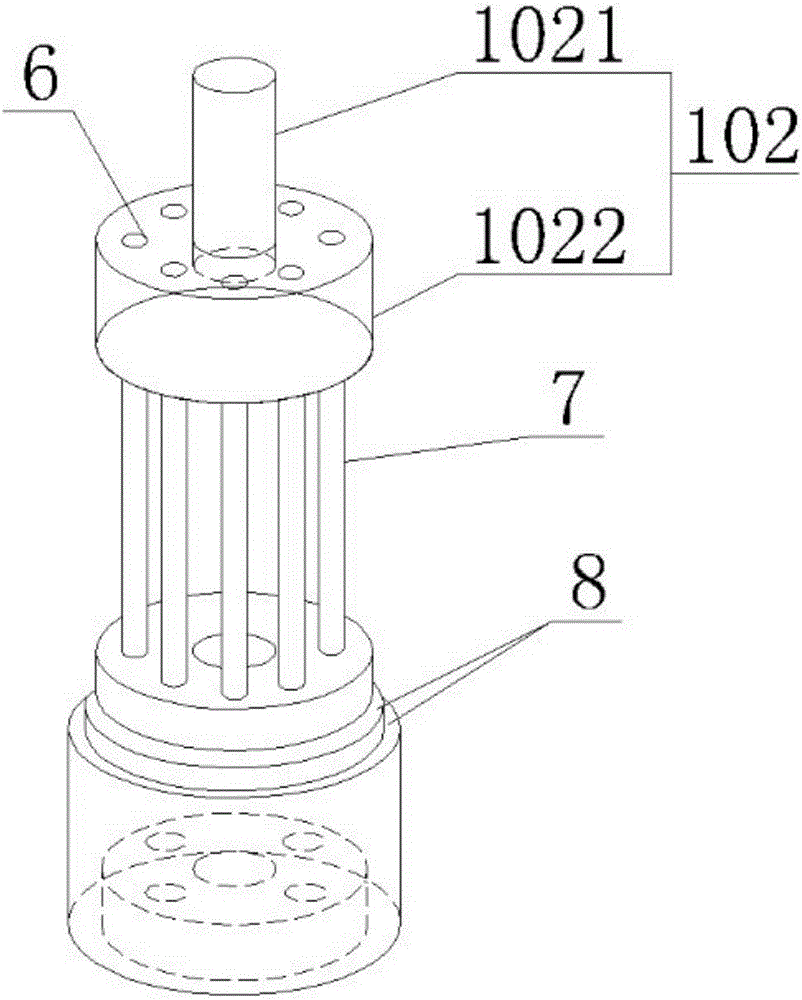

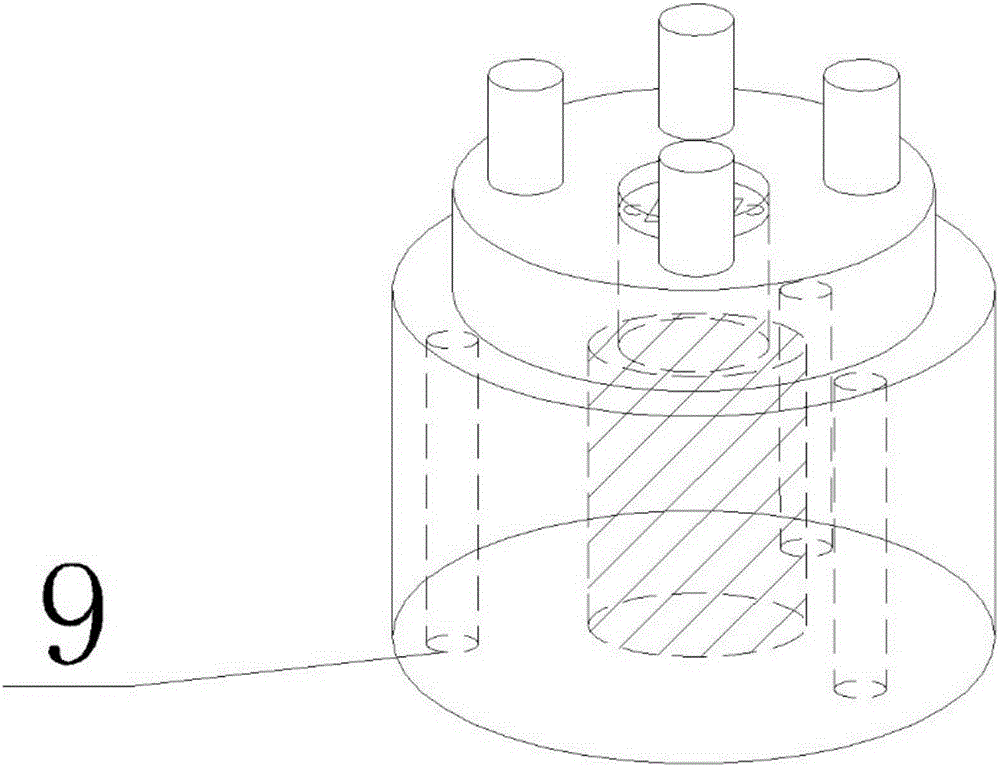

[0016] See the accompanying drawings: a novel vertical pump impeller bottom cover rapid prototyping die, including a rapid pressing upper die 1 and a double positioning column guiding lower die 2, characterized in that: the rapid pressing upper die 1 is fixed by an upper plate 101 The guide connecting part 102 and the delivery pressing part 103 are composed. The upper part of the fixed guiding connecting part 102 is a smooth cylindrical connecting rod 1021 embedded in the upper plate 101, which can be fixed on the punching machine. The fixed guiding connecting part 102 The lower part is a disc-shaped transmission pressure table 1022, and the above-mentioned press-forming part 103 is a pressure-applying table holder, and the upper part of the pressure-applying table holder is slidably fixed by 8 lock rods 7 with sleeves and the disk-shaped transmission pressure table. The lower part of the table 1022 is connected, and the double positioning column guide lower mold 2 is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com