Machine for cutting head and end of corn

A corn and head cutting technology, which is applied in metal processing and other directions, can solve the problems of low pass rate, inconsistent product specifications, and failure to meet market demand, etc., and achieve the effect of high work efficiency and neat incision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

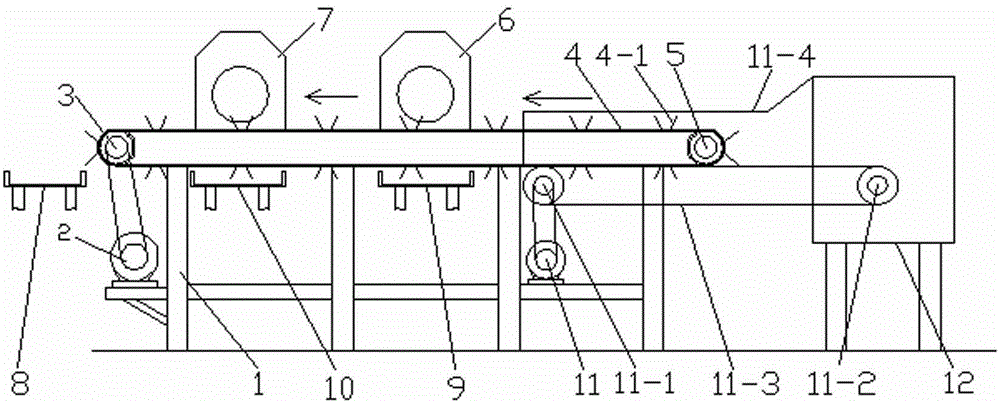

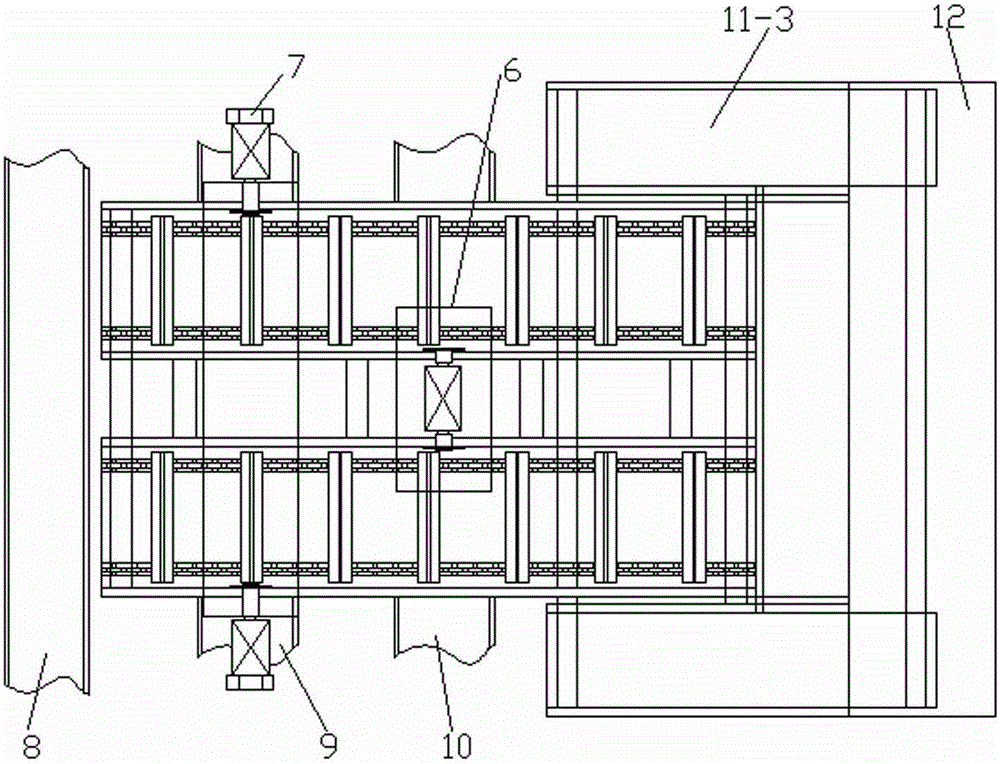

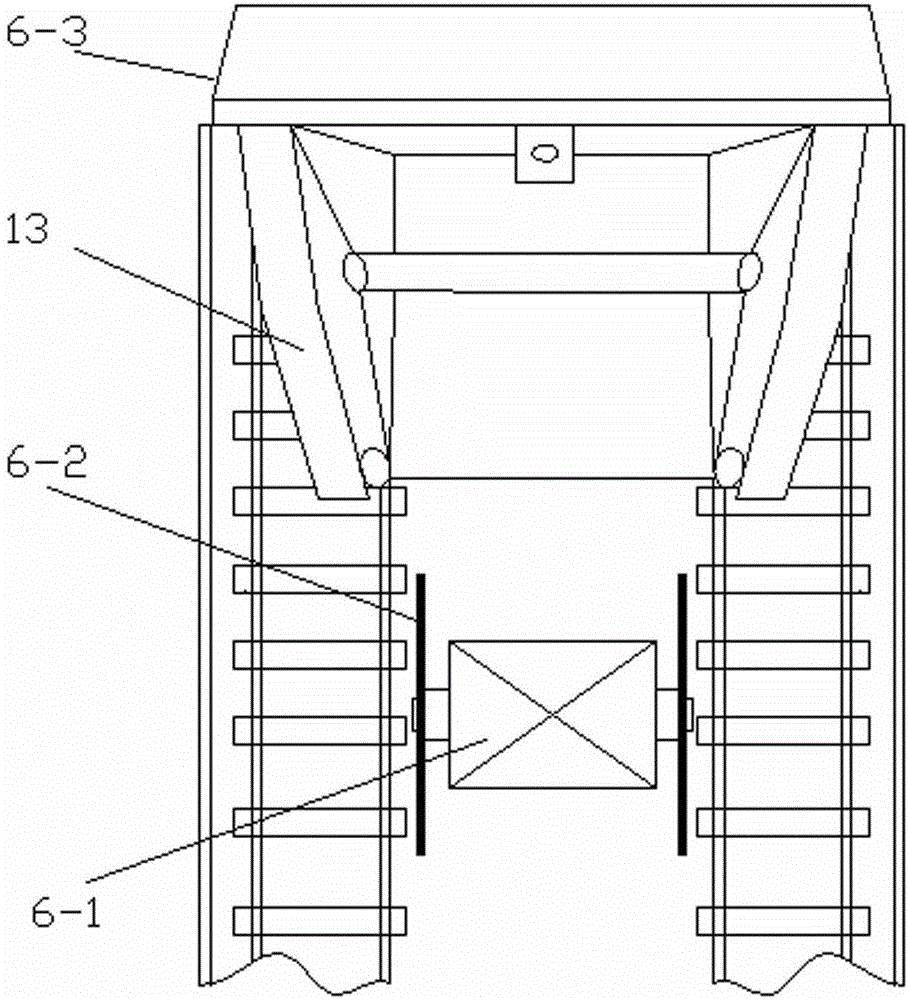

[0026] Such as Figure 1~4 As shown, a corn cutting head and tail cutting machine includes a frame 1, a first drive motor 2 is installed on the frame 1, a main transmission shaft 3 is provided at one end of the top of the frame, and an auxiliary transmission shaft is provided at the other end 5. The first driving motor 2 is connected to the main transmission shaft 3 through a sprocket chain, and the main transmission shaft 3 and the auxiliary transmission shaft 5 are connected through a transmission belt 4, and a corn storage device is installed on the transmission belt 4 41; the top of the conveyor belt 4 is sequentially provided with a first cutting device 6 and a second cutting device 7 for cutting off the corn tail or head, and the first cutting device 6 and the second cutting device 7 are equipped with corn The pressing device 13 that compresses when cutting off, and the below of the conveyor belt 4 corresponding to the first cutting device 6 and the second cutting device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com