Preparation method of lamellar stacking titanium dioxide nanoparticles

A technology of titanium dioxide and nanoparticles, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., to achieve the effect of simple process steps, good process stability and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Take 1g of Ti 3 AlC 2 , added to 10mL, 40% hydrofluoric acid, and magnetically stirred for 24 hours;

[0031] 2. Centrifuge and wash the stirred solution to pH=6, vacuum at 1000 Pascals, and dry for 12 hours to obtain the two-dimensional material MXene;

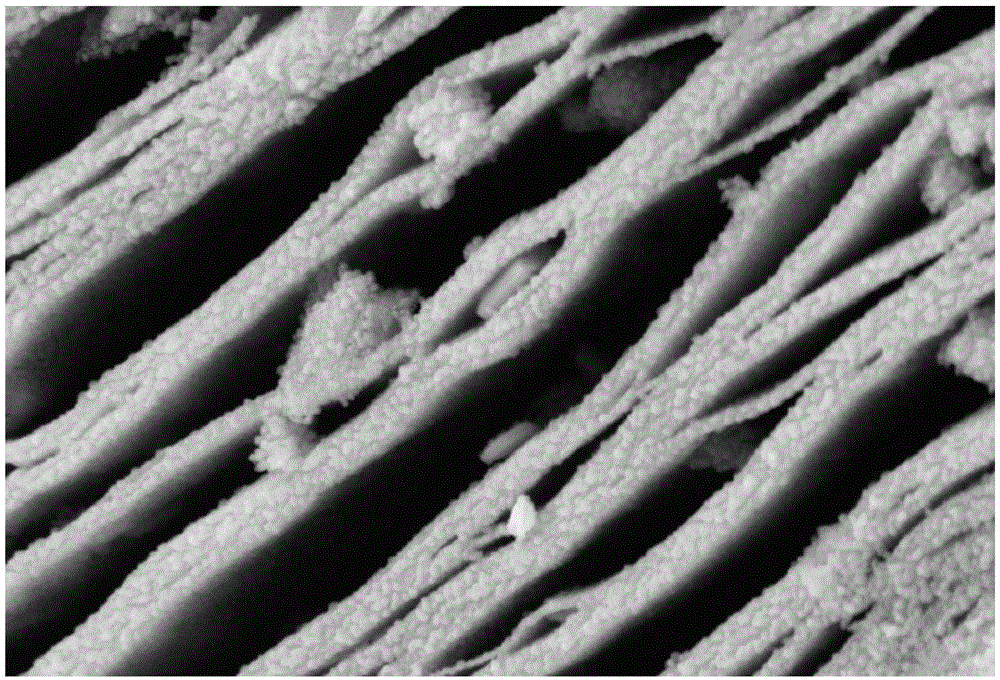

[0032] 3. Take 0.2g of MXene, add it to 20mL of deionized water, heat at 200°C for 5 hours, then centrifuge and wash until pH=7, vacuum at 1000 Pascals, and dry for 12 hours;

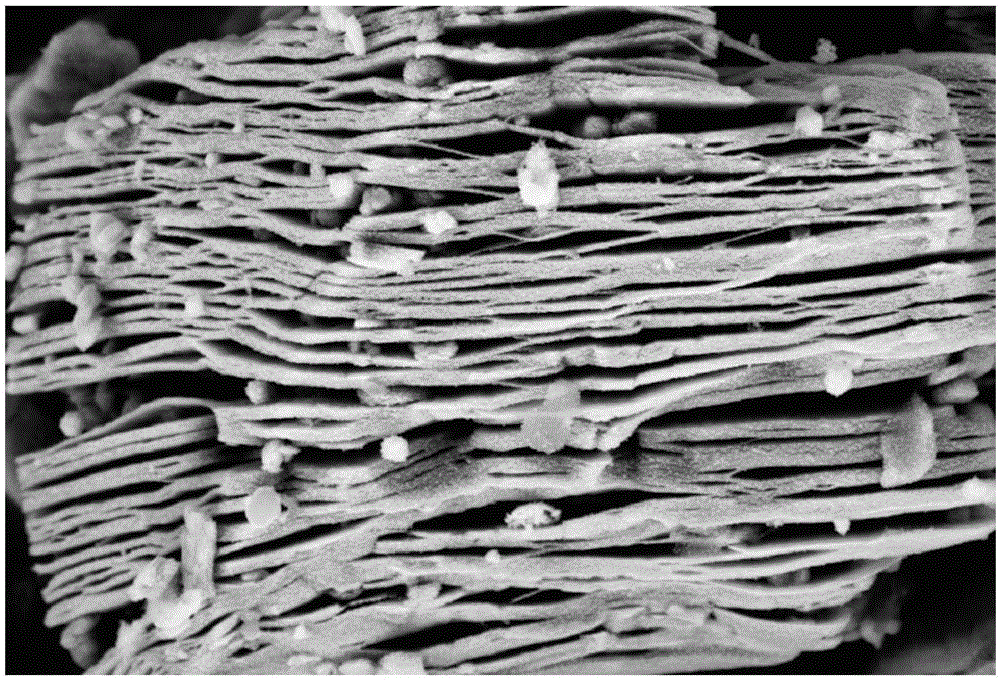

[0033] 4. Put the dried product into a high-temperature furnace, oxidize it at 300°C for 3 hours, and the obtained product is layered stacked titanium dioxide nanoparticles.

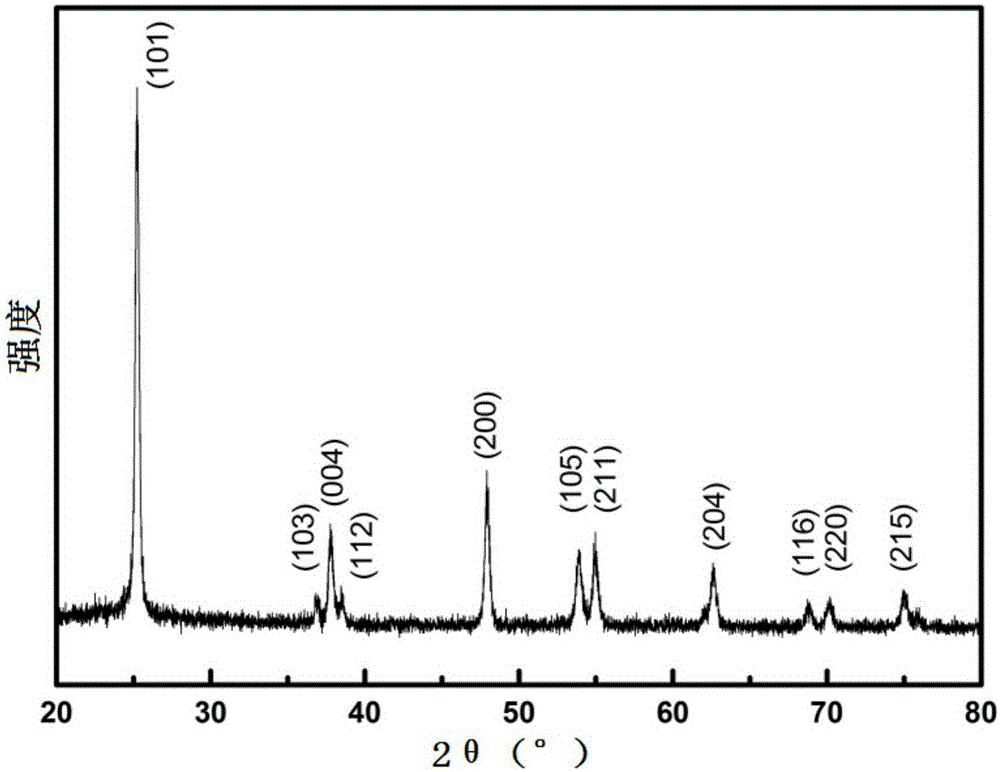

[0034] See attached figure 1 , which is the XRD spectrum of titanium dioxide nanoparticles provided in this implementation case. It can be seen from the figure that, compared with the standard card JCPDSNo.21-1272, its XRD diffraction peaks completely correspond to the standard spectrum of anatase titanium dioxide, and 11 diffraction peaks correspond to (101), (103)...

Embodiment 2

[0038] The present embodiment is a kind of preparation method of layered stacking titanium dioxide nanoparticles, the method is based on Ti 3 AlC 2 As raw material, acidic solution was used to corrode Ti 3 AlC 2, remove the Al atomic layer to generate the two-dimensional material MXene, and then use the two-dimensional material MXene as a precursor to undergo a hydrothermal reaction and an oxidation reaction in turn to obtain the layered stacked titanium dioxide nanoparticles, which specifically include the following steps:

[0039] (1) the preparation mass concentration is the acidic solution of 60%, adds Ti 3 AlC 2 , fully stirred, and then centrifuged and washed until the pH of the supernatant was 5, and vacuum-dried to obtain the two-dimensional material MXene;

[0040] (2) Add the two-dimensional material MXene prepared in step (1) into deionized water, transfer it to a hydrothermal reaction kettle, and perform a hydrothermal reaction. After the reaction is completed,...

Embodiment 3

[0047] The present embodiment is a kind of preparation method of layered stacking titanium dioxide nanoparticles, the method is based on Ti 3 AlC 2 As raw material, acidic solution was used to corrode Ti 3 AlC 2 , remove the Al atomic layer to generate the two-dimensional material MXene, and then use the two-dimensional material MXene as a precursor to undergo a hydrothermal reaction and an oxidation reaction in turn to obtain the layered stacked titanium dioxide nanoparticles, which specifically include the following steps:

[0048] (1) Prepare an acidic solution with a mass concentration of 10%, add Ti 3 AlC 2 , fully stirred, and then centrifuged and washed until the pH of the supernatant was 7, and vacuum-dried to obtain the two-dimensional material MXene;

[0049] (2) Add the two-dimensional material MXene prepared in step (1) into deionized water, transfer it to a hydrothermal reaction kettle, and perform a hydrothermal reaction. After the reaction is completed, cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com