Anaerobic particle sludge rapid culture method suitable for oil refining and chemical engineering wastewater treatment

A technology for anaerobic granular sludge and chemical wastewater, applied in the direction of anaerobic digestion treatment, waste fuel, etc., can solve the problem of the decrease of microbial-pollutant mass transfer efficiency, the difficulty of increasing the concentration of anaerobic sludge, and the formation of anaerobic granular sludge Difficulties and other problems, to achieve the effects of strong resistance to water quality and environmental conditions, improved treatment efficiency, and increased microbial biomass per unit volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

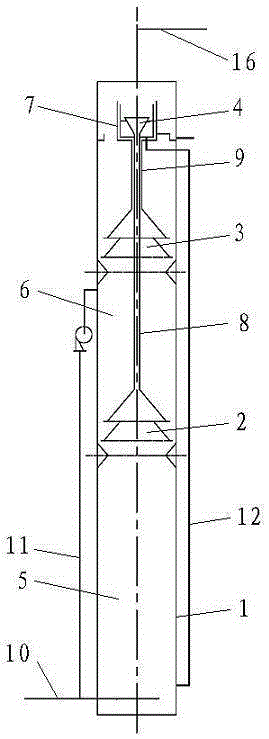

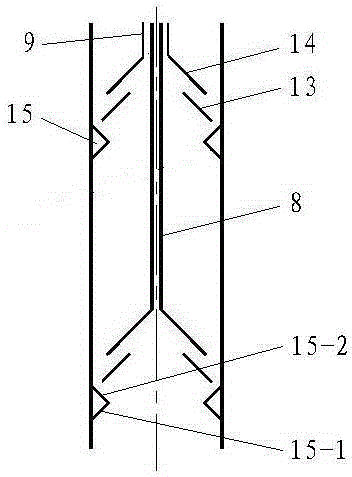

[0025] The invention provides a rapid cultivation method of anaerobic granular sludge suitable for oil refinery and chemical wastewater treatment, which mainly includes the following two steps: (1) domestication: taking facultative sludge from the biochemical process of sewage treatment plant as inoculation sludge Use sodium acetate solution as the organic substrate at the initial stage of cultivation, and as the cultivation progresses, add oil refining and chemical wastewater to the organic substrate and gradually increase the blending ratio of refining and chemical wastewater until the organic The substrate is domesticated and cultivated to form an efficient anaerobic sludge system; (2) Granulation: acrylamide polymer and peat soil are used as composite nucleating agents, and are added to the domesticated anaerobic sludge in batches and multiple times , to promote the nucleation and granulation of anaerobic sludge to form more efficient anaerobic granular sludge.

[0026]The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com