A kind of flame-retardant ABS composite material and preparation method thereof

A composite material and mixed material technology, applied in the field of flame retardant materials, can solve the problems of restricting the application of flame retardant ABS materials, poor physical properties, complex components, etc., and achieve the effects of excellent mechanical properties, high surface energy, and improved mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

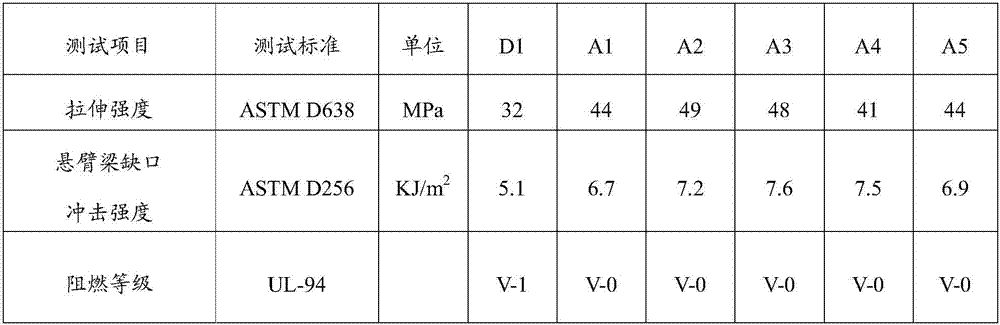

Examples

Embodiment 1

[0028] (1) Weigh 70 parts of ABS, 16 parts of LDH-SEP, 8 parts of APP, 10 parts of PER, 0.05 parts of Irganox168 and 0.05 parts of Irganox1010 and mix and stir them to obtain a mixture;

[0029] (2) Put the mixture obtained in step (1) into the hopper of the twin-screw extruder for extruding and granulation to obtain the flame-retardant ABS composite material A1, where the temperature of the first temperature zone of the twin-screw extruder The temperature is 190°C, the temperature in the second temperature zone is 230°C, the temperature in the third temperature zone is 230°C, the temperature in the fourth temperature zone is 230°C, the temperature in the fifth temperature zone is 230°C, and the temperature in the sixth temperature zone is 230°C. The temperature is 230°C, the head temperature of the twin-screw extruder is 230°C, and the screw speed is 200r / min.

Embodiment 2

[0031] (1) Weigh 90 parts of ABS, 24 parts of LDH-SEP, 12 parts of APP, 16 parts of PER, 0.3 part of Irganox 1010 and 0.2 part of Irganox 1330, mix and stir to obtain a mixture by weight;

[0032] (2) Put the mixture obtained in step (1) into the hopper of the twin-screw extruder to be extruded and pelletized to obtain the flame-retardant ABS composite material A2, wherein the temperature of the first temperature zone of the twin-screw extruder The temperature is 210°C, the temperature in the second temperature zone is 270°C, the temperature in the third temperature zone is 270°C, the temperature in the fourth temperature zone is 270°C, the temperature in the fifth temperature zone is 270°C, and the temperature in the sixth temperature zone is 270°C. The temperature is 270°C, the head temperature of the twin-screw extruder is 270°C, and the screw speed is 260r / min.

Embodiment 3

[0034] (1) Weigh 80 parts of ABS, 20 parts of LDH-SEP, 10 parts of APP, 13 parts of PER, 0.1 part of Irganox168 and 0.1 part of Irganox1010 by weight, mix and stir to obtain a mixture;

[0035] (2) Put the mixture obtained in step (1) into the hopper of the twin-screw extruder for extruding and granulation to obtain the flame-retardant ABS composite material A3, where the temperature of the first temperature zone of the twin-screw extruder The temperature is 200°C, the temperature in the second temperature zone is 250°C, the temperature in the third temperature zone is 250°C, the temperature in the fourth temperature zone is 250°C, the temperature in the fifth temperature zone is 250°C, and the temperature in the sixth temperature zone is 250°C. The temperature is 250°C, the head temperature of the twin-screw extruder is 250°C, and the screw speed is 230r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com