Printing-dyeing technology for denim with fast color

A printing and dyeing process, denim technology, applied in the direction of printing, dyeing, printing devices, etc., can solve the problems of denim easy to fade, increase workload, and clothes are worn out, so as to improve product style, reduce viscosity, and easy to color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A non-bleaching denim printing and dyeing process, the gray fabric is elastic denim knitted fabric, comprising the following steps:

[0046] (1) Pre-treatment gray cloth: treat the gray cloth with alkali, refining agent and hydrogen peroxide, and dehydrate and shape it;

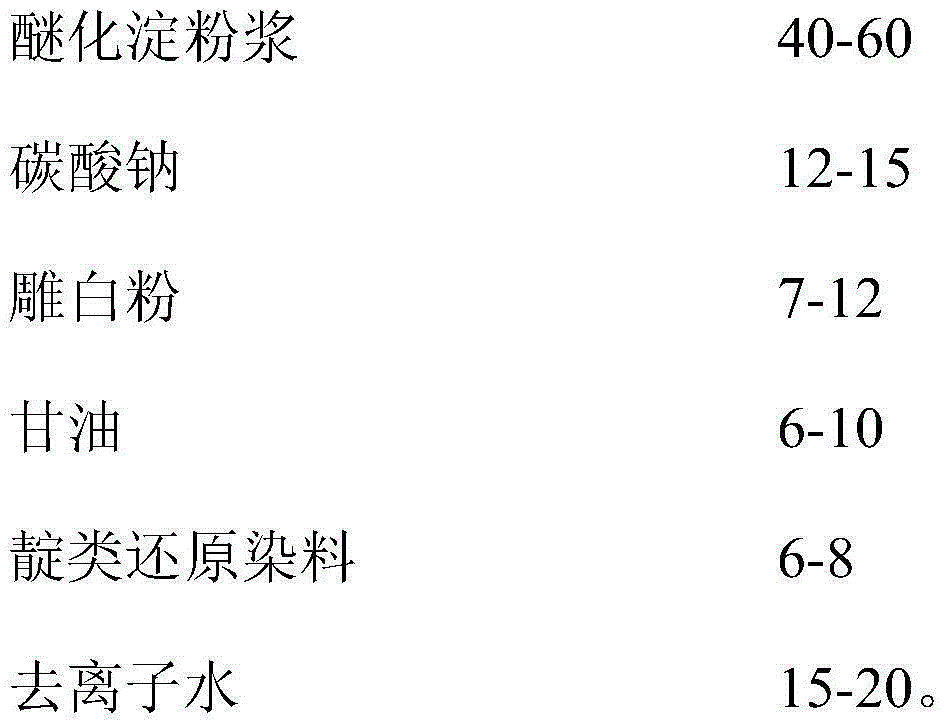

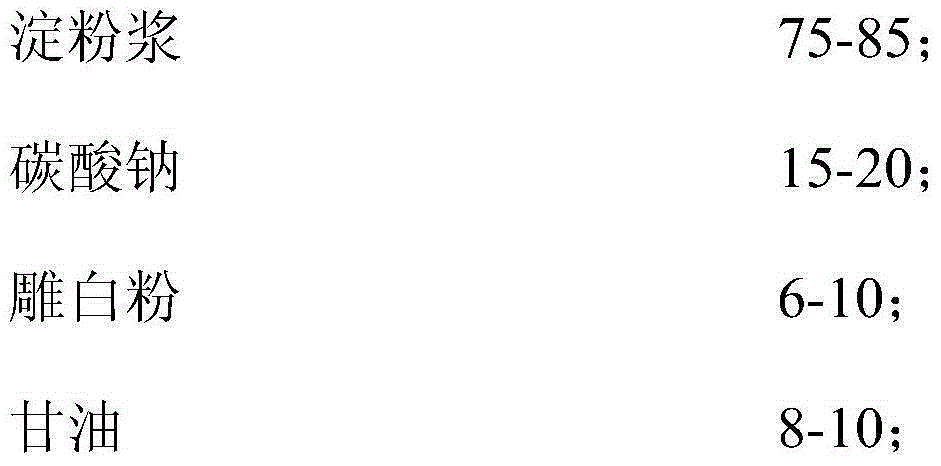

[0047] (2) Slurry printing: Prepare the printing paste, and its viscosity is controlled at 16000Pa·S. After the preparation is uniform, filter it with a 30-mesh screen, then filter it with a 55-mesh screen, pretreat it with ultrasonic waves for 60 minutes, and then use a flat screen printing machine Dyeing and printing, drying at 110°C;

[0048] (3) Steaming: After steaming at 110°C for 15 minutes, increase the temperature to 125°C for 8 minutes;

[0049] (4) Water washing: select a continuous rope washing machine, the first three are washed with cold water, the fourth is washed with hot water, the last two are washed with cold water, and the centrifuge is dehydrated;

[0050] (5) Soaking: Soak with ...

Embodiment 2

[0059] A non-bleaching denim printing and dyeing process, the gray fabric is elastic denim knitted fabric, comprising the following steps:

[0060] (1) Pre-treatment gray cloth: treat the gray cloth with alkali, refining agent and hydrogen peroxide, and dehydrate and shape it;

[0061] (2) Slurry printing: Prepare the printing paste, and its viscosity is controlled at 17000Pa·S. After the preparation is uniform, filter it with a 40-mesh screen, then filter it with a 60-mesh screen, pretreat it with ultrasonic waves for 80 minutes, and then use a flat screen printing machine Dyeing and printing, drying at 113°C;

[0062] (3) Steaming: After steaming at 113°C for 12 minutes, increase the temperature to 124°C for 9 minutes;

[0063] (4) Water washing: select a continuous rope washing machine, the first three are washed with cold water, the fourth is washed with hot water, the last two are washed with cold water, and the centrifuge is dehydrated;

[0064] (5) Soaking: Soak with ...

Embodiment 3

[0074] A non-bleaching denim printing and dyeing process, the gray fabric is elastic denim knitted fabric, comprising the following steps:

[0075] (1) Pre-treatment gray cloth: treat the gray cloth with alkali, refining agent and hydrogen peroxide, and dehydrate and shape it;

[0076] (2) Slurry printing: Prepare the printing paste, and its viscosity is controlled at 18000Pa·S. After the preparation is uniform, filter it with a 50-mesh screen, then filter it with a 65-mesh screen, pretreat it with ultrasonic waves for 80 minutes, and then use a flat screen printing machine Dyeing and printing, drying at 115°C;

[0077] (3) Steaming: After steaming at 115°C for 10 minutes, increase the temperature to 125°C for 8 minutes;

[0078] (4) Water washing: select a continuous rope washing machine, the first three are washed with cold water, the fourth is washed with hot water, the last two are washed with cold water, and the centrifuge is dehydrated;

[0079] (5) Soaking: Soak with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com