A kind of environment-friendly carbonless copy paper and preparation method thereof

A carbon-free copy paper, environmentally friendly technology, applied in the direction of special paper, paper, papermaking, etc., can solve the problems of product quality impact, high solid content, low formaldehyde content, etc., to achieve the reduction of free formaldehyde content, stable formaldehyde content, low The effect of formaldehyde content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

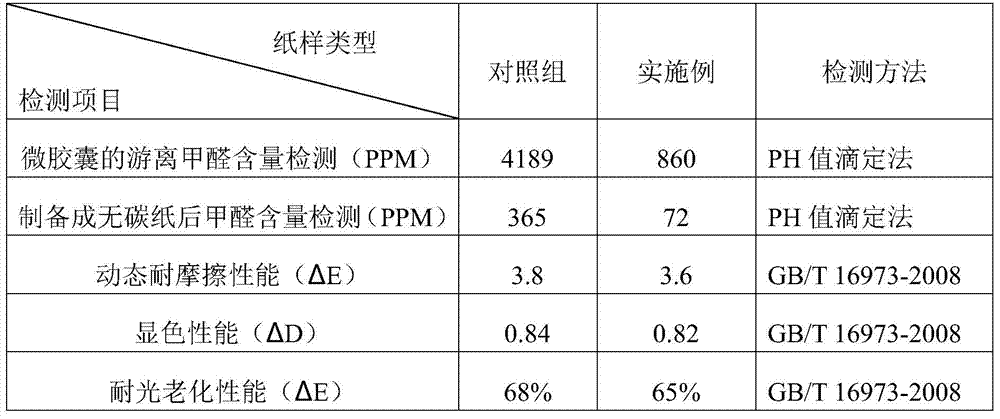

Embodiment 1

[0024] (1) Production method of blue three-stage aldehyde-removing environmentally friendly carbonless copy paper

[0025] Production of carbonless base paper: It is consistent with the known papermaking process, the main difference is that the raw materials used are all without adding any formaldehyde components or substances that may react to form formaldehyde components.

[0026] Preparation of blue microcapsules: use blue color leuco dye, dissolve in diaryl ethane type solvent oil and form leuco dye color oil. According to a certain proportion of ingredients, a small amount of wall shell materials used are shell wall materials containing formaldehyde components such as melamine formaldehyde resins known in the industry, emulsifiers and color oils, and microcapsules for carbon-free paper are prepared using known in-situ polymerization methods , after the particle size of the required microcapsules is reached in the emulsification stage, add oligomeric water-soluble chitin a...

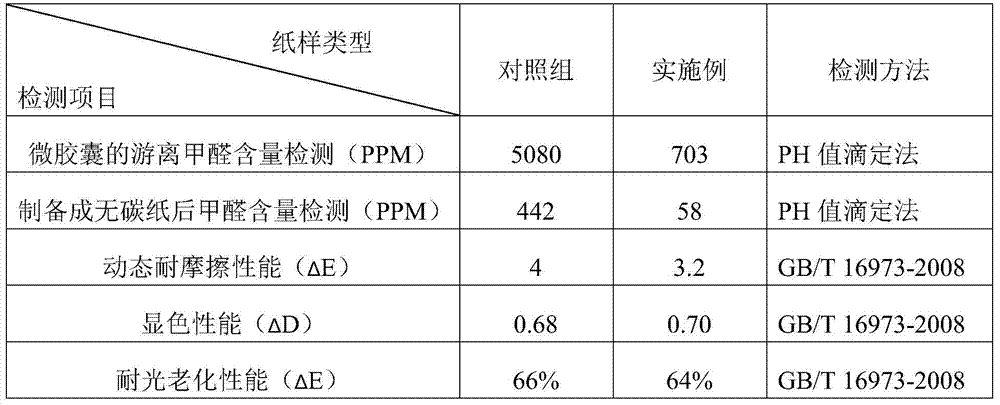

Embodiment 2

[0034] (1) Production method of black second-stage aldehyde-removing environmentally friendly carbonless copy paper

[0035] Production of carbonless base paper: consistent with the method of Example 1.

[0036]Preparation of leuco-dye microcapsules: use a black-colored leuco-dye, dissolve it in a diaryl alkanes-type solvent oil, and form a leuco-dye color oil. The preparation method of microcapsule is consistent with example 1, and difference is: microcapsule adds chitooligosaccharide water-soluble substance and accounts for 5~8% of total dry matter supplementing as shell wall material in the forming stage of microcapsule, then in the curing stage of microcapsule again Adding 7.5-12% as a supplement to the shell wall material finally prepares black microcapsules with good mechanical strength, high stability and good stability.

[0037] Preparation of environmentally friendly carbon-free coatings: use black dye microcapsules 30-50%, modified starch 7-12%, modified corn starch...

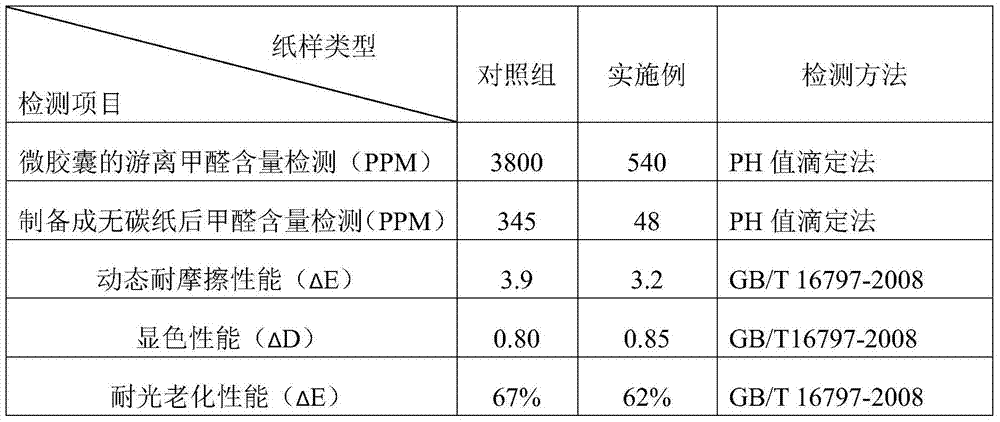

Embodiment 3

[0044] (1) Production method of blue-colored second-stage aldehyde-removing environmentally friendly carbonless copy paper

[0045] Production of carbonless base paper: consistent with the method of Example 1.

[0046] The preparation of leuco dye microcapsules: the preparation method of leuco dye oil-soluble, microcapsules is consistent with example 1, difference is: microcapsules add chitin deacetylation modification in emulsification stage and account for 1~2% of total microcapsule dry material. 4% is used as a supplement for the shell wall material, and then 10-15% is added as a supplement for the shell wall material during the curing stage of the microcapsules, and finally blue microcapsules with good mechanical strength and good stability are prepared.

[0047] Preparation of environmentally friendly carbon-free coatings: use blue dye microcapsules 35-65%, modified starch 30-45%, styrene-butadiene latex 1-5%, sodium carboxymethyl cellulose 0.1-1.5%, potassium tripolyphos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com