Armal power generation unit main steam pressure optimization control method

A thermal power generation unit, main steam pressure technology, applied in the direction of combustion method, combustion control, fuel supply adjustment, etc., can solve the mismatch and contradiction between main steam pressure adjustment and unit load demand, affecting boiler combustion stability and unit load Response performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

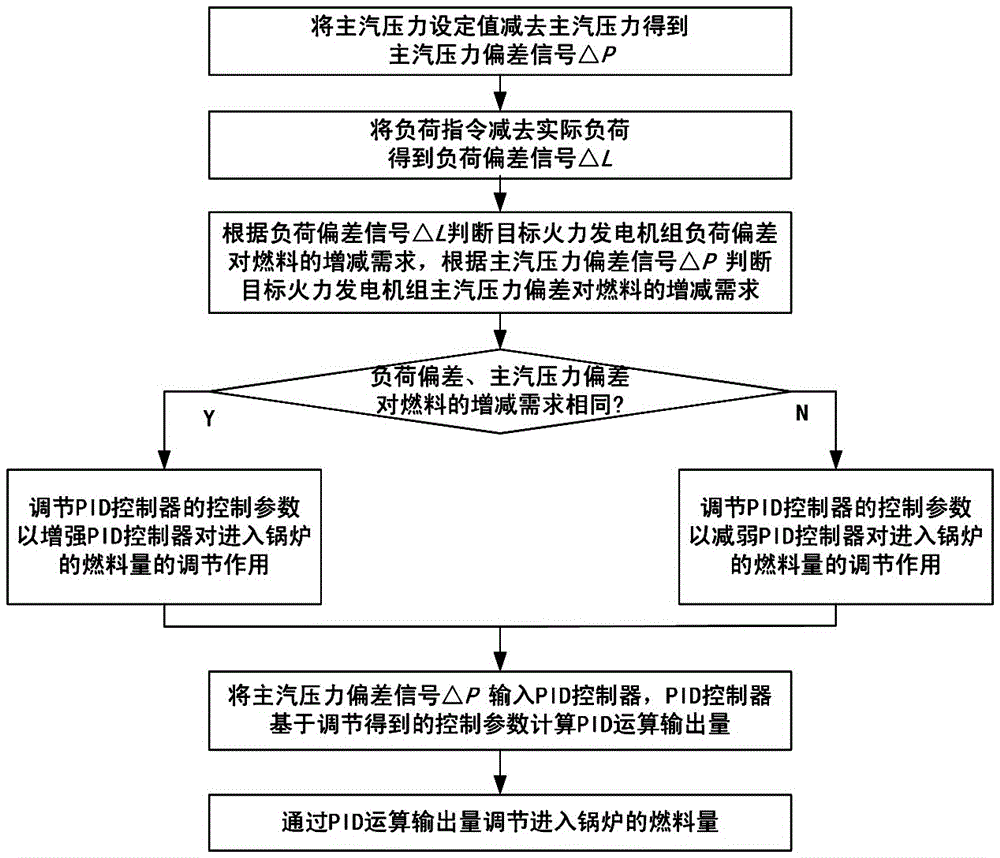

[0025] like figure 1 As shown, the steps of the method for optimizing the main steam pressure of the thermal power generating set in this embodiment include:

[0026] 1) Subtract the main steam pressure from the main steam pressure setting value of the target thermal power generating unit to obtain the main steam pressure deviation signal△ P ;

[0027] 2) Subtract the actual load from the load command of the target thermal power generating unit to obtain the load deviation signal△ L ;

[0028] 3) According to the load deviation signal △ L Judging the demand for fuel increase or decrease due to the load deviation of the target thermal power generation unit, according to the main steam pressure deviation signal △ PJudging the increase or decrease demand for fuel by the main steam pressure deviation of the target thermal power generating set; adjusting the control parameters of the PID controller according to the increase or decrease demand for fuel by the load deviation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com