Boiler combustion optimization method and system based on AGC mode and adjustment system

A technology of boiler combustion and optimization method, which is applied in the control of combustion, lighting and heating equipment, etc., can solve the problems of poor combustion stability, low temperature of denitrification and ammonia injection system cannot be put into operation normally, and boiler operating parameters deviate greatly from design parameters. Guarantee stability, expand the range of deep peak shaving capabilities, and improve the effect of drying output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The principles and features of the present invention will be described below with reference to the accompanying drawings. The embodiments are only used to explain the present invention, but not to limit the scope of the present invention.

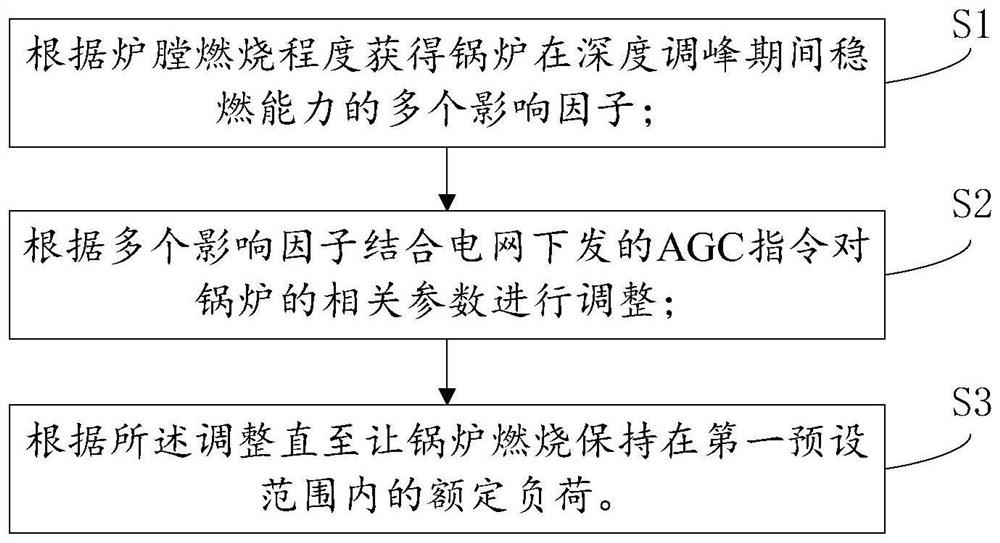

[0069] like figure 1 As shown, a kind of boiler combustion optimization method based on AGC mode provided by the embodiment of the present invention includes:

[0070] S1, according to the combustion degree of the furnace chamber, obtain multiple influencing factors that affect the stable combustion capability of the boiler during the deep peak regulation period; it should be noted that, in a certain embodiment, the multiple influencing factors may include: furnace air leakage rate, improving pulverizing The drying output of the system, the adjustment of the secondary air distribution, the plasma combustion support and the operation mode of the pulverizing system.

[0071] S2, adjust the relevant parameters of the boiler according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com