Mixing condensing system based on up-in-down-out superposed double-flow-path steam condenser

A mixed condensation and condenser technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of affecting the service life of the operation effect, cavitation of vacuum pumps, large steam content, etc., and improve thermal economy. , The effect of reducing the exhaust pressure of the turbine and the short main flow process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but the embodiments should not be construed as limiting the present invention, but only as examples, and the advantages of the present invention will become clearer and easier to understand.

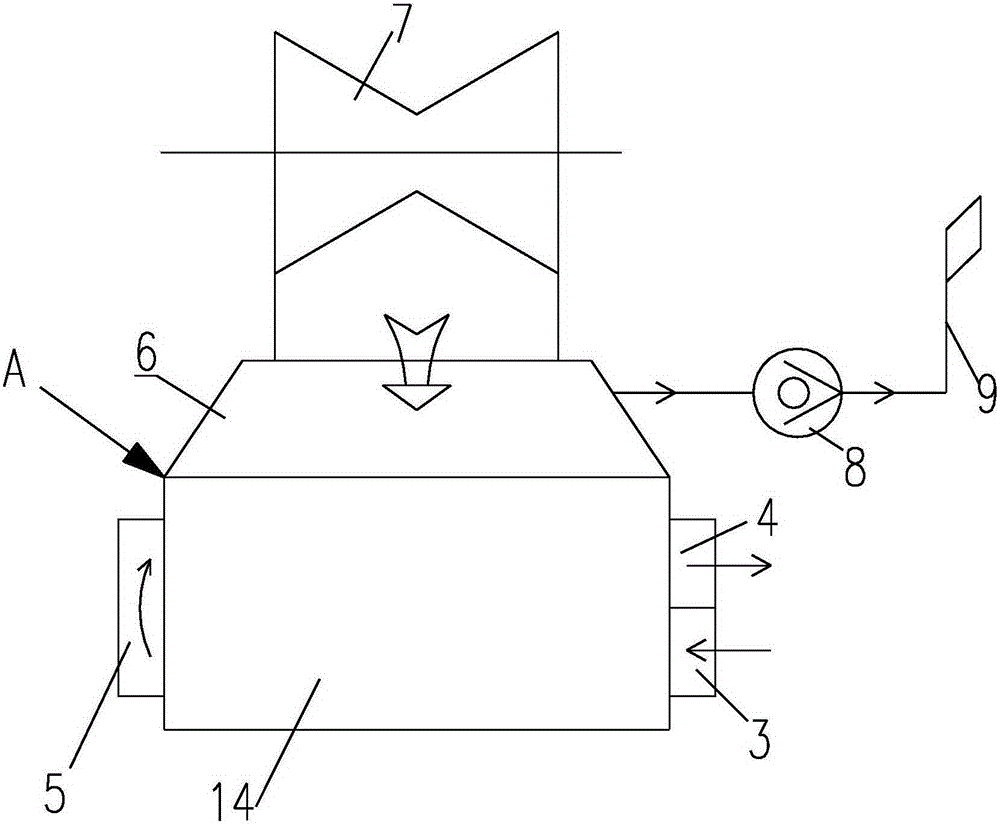

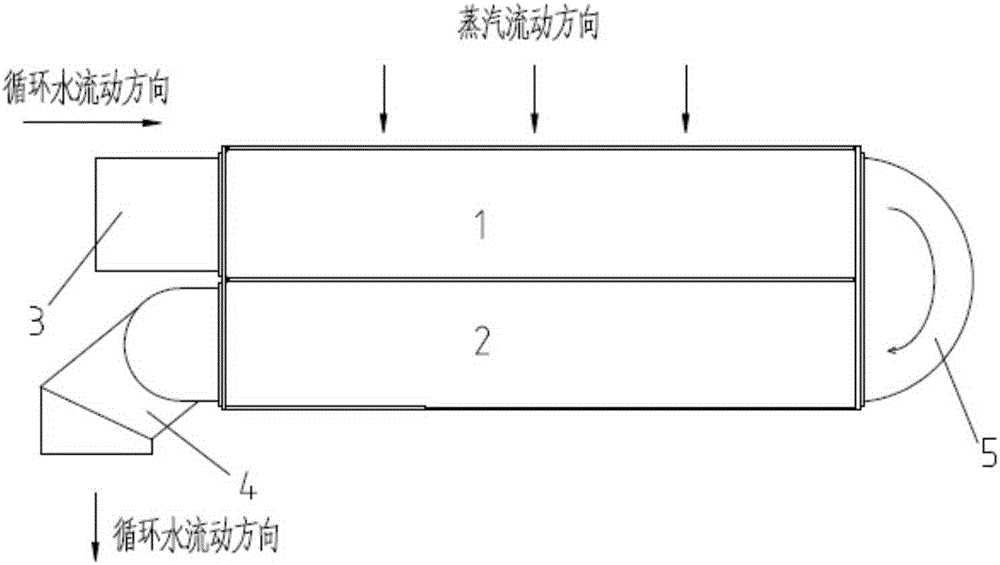

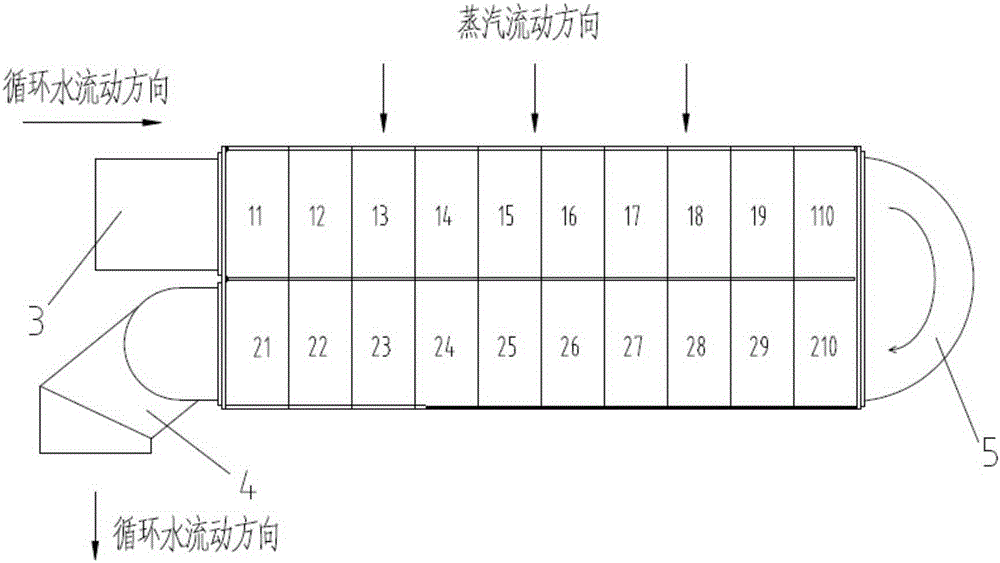

[0026] As shown in the figure, the hybrid condensing system based on stacked double-flow condensers with top in and bottom out includes condenser A. Condenser A includes a condenser heat exchange area 14, and the upper end of the condenser heat exchange area 14 is set There is a condenser throat 6, and the upper end of the condenser throat 6 is provided with a low-pressure cylinder 7; one side of the condenser heat exchange area 14 is provided with a rear water chamber 5, and the other side of the condenser heat exchange area 14 is provided with a circulation The cooling water inlet pipe 3 and the circulating cooling water outlet 4, the condenser heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com