Image sensor and forming method thereof

An image sensor and semiconductor technology, which is applied in the field of image sensors, can solve the problems of pixel unit ratio limitation, increase of low-frequency 1/f noise, and decrease of dynamic range, etc., to achieve quality improvement, strong channel control, and performance improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

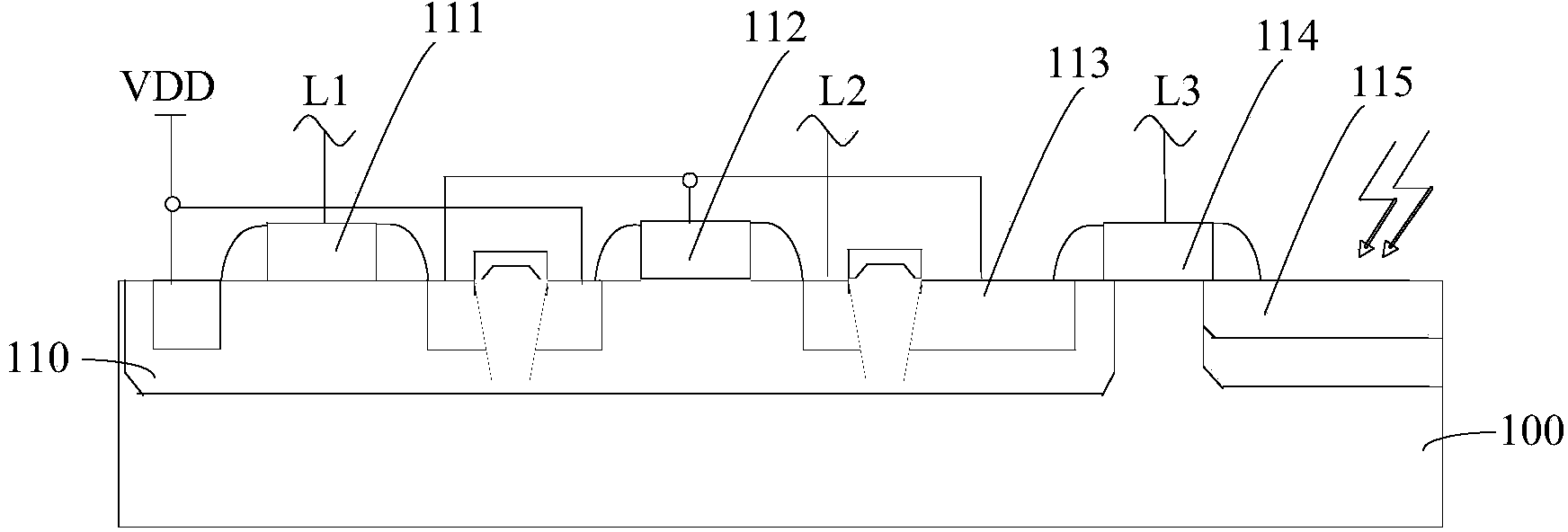

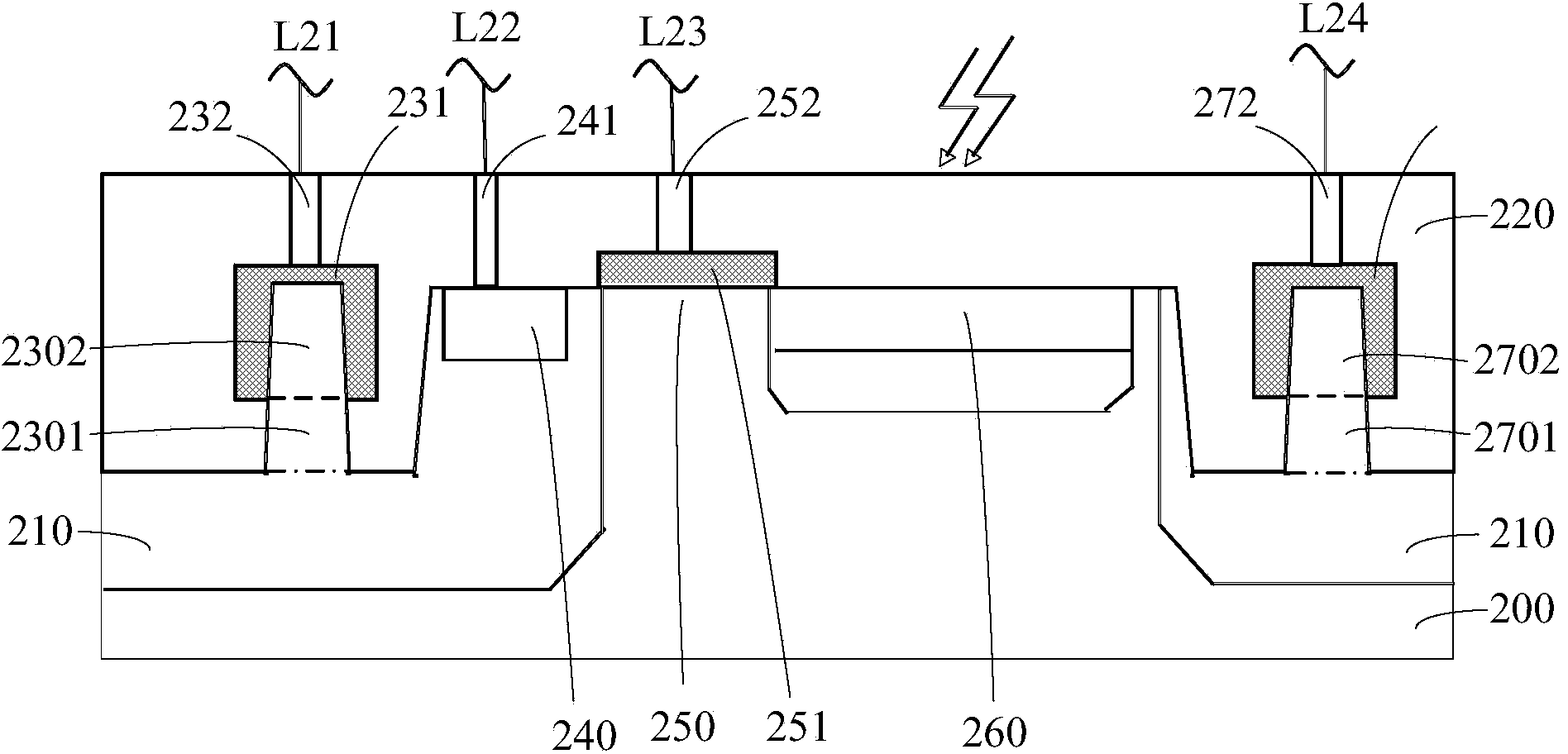

[0066] In existing image sensors, transistors (such as source follower transistors, transfer transistors, and reset transistors, etc.) are usually planar structures. Therefore, the corresponding pixel units have many defects. For example, it is difficult to further reduce the chip area of image sensors. The cost remains high, the image quality formed by the image sensor is difficult to further improve, the noise level of the image sensor is difficult to reduce, and the area occupancy rate of the photoelectric conversion element in the pixel unit is difficult to increase.

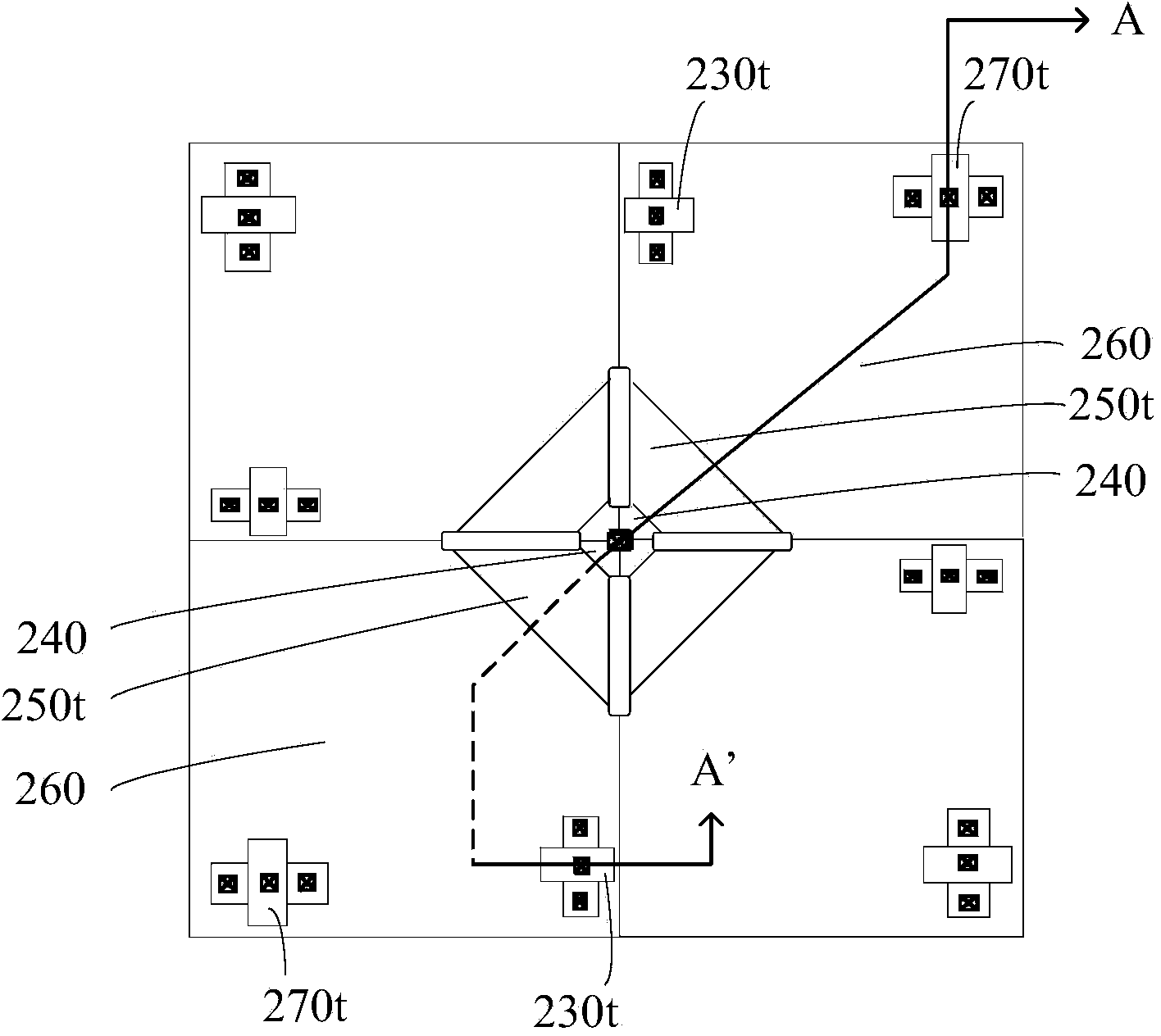

[0067] For this reason, the present invention proposes a kind of image sensor, in the image sensor provided by the present invention, pixel unit has the source follower transistor of three-dimensional structure, so the performance of pixel unit improves, thereby can improve the image quality that image sensor produces, also can At the same time, the performance of the image sensor chip can be improved, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com