A Prefabrication Method of Standard Roughness Joint Surface of Quasi-rock Specimens

A technology of rock specimen and joint surface is applied in the field of rock mechanics experiment, which can solve the problems of inability to realize prefabricated joint surface, high requirements for equipment and complex production process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

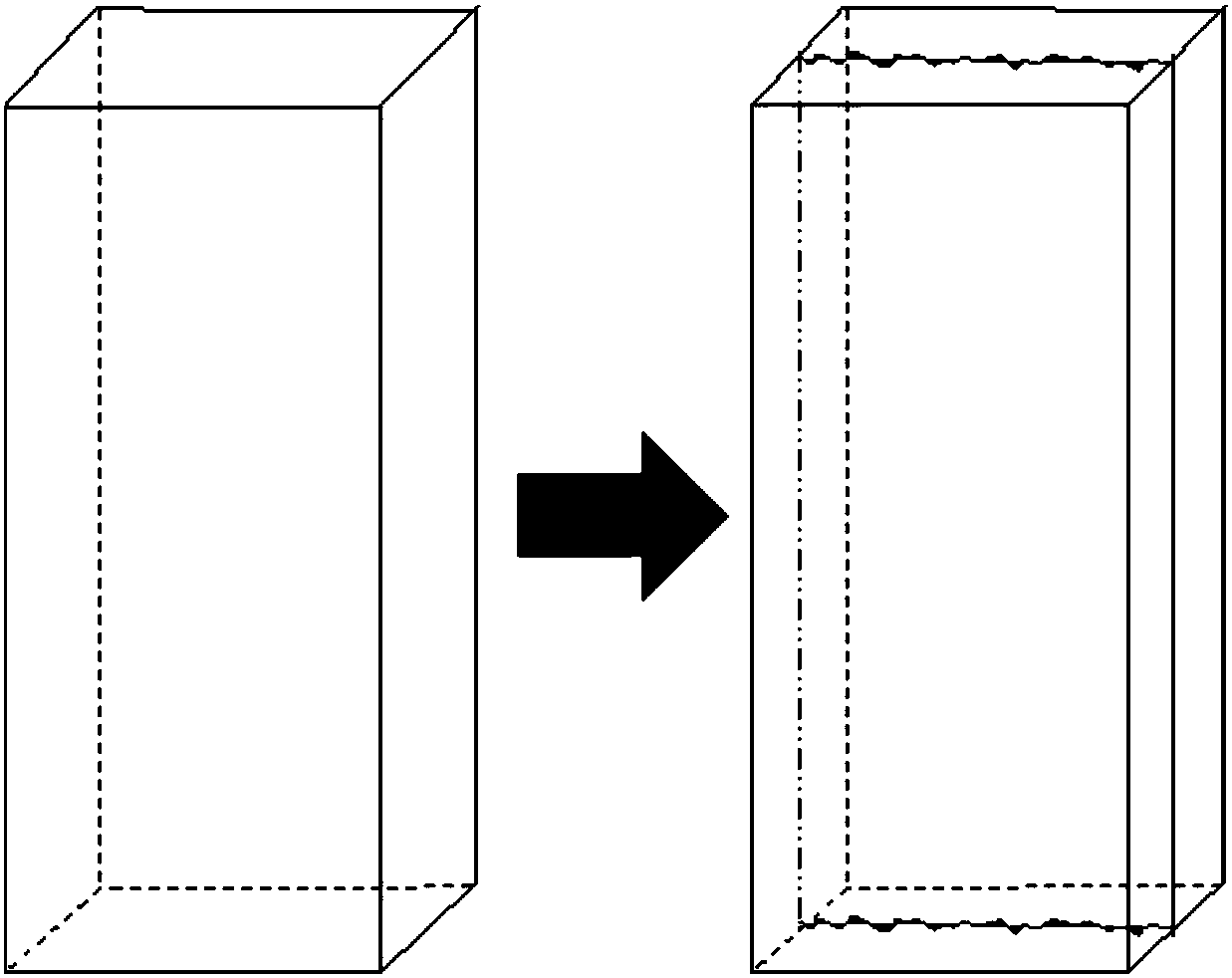

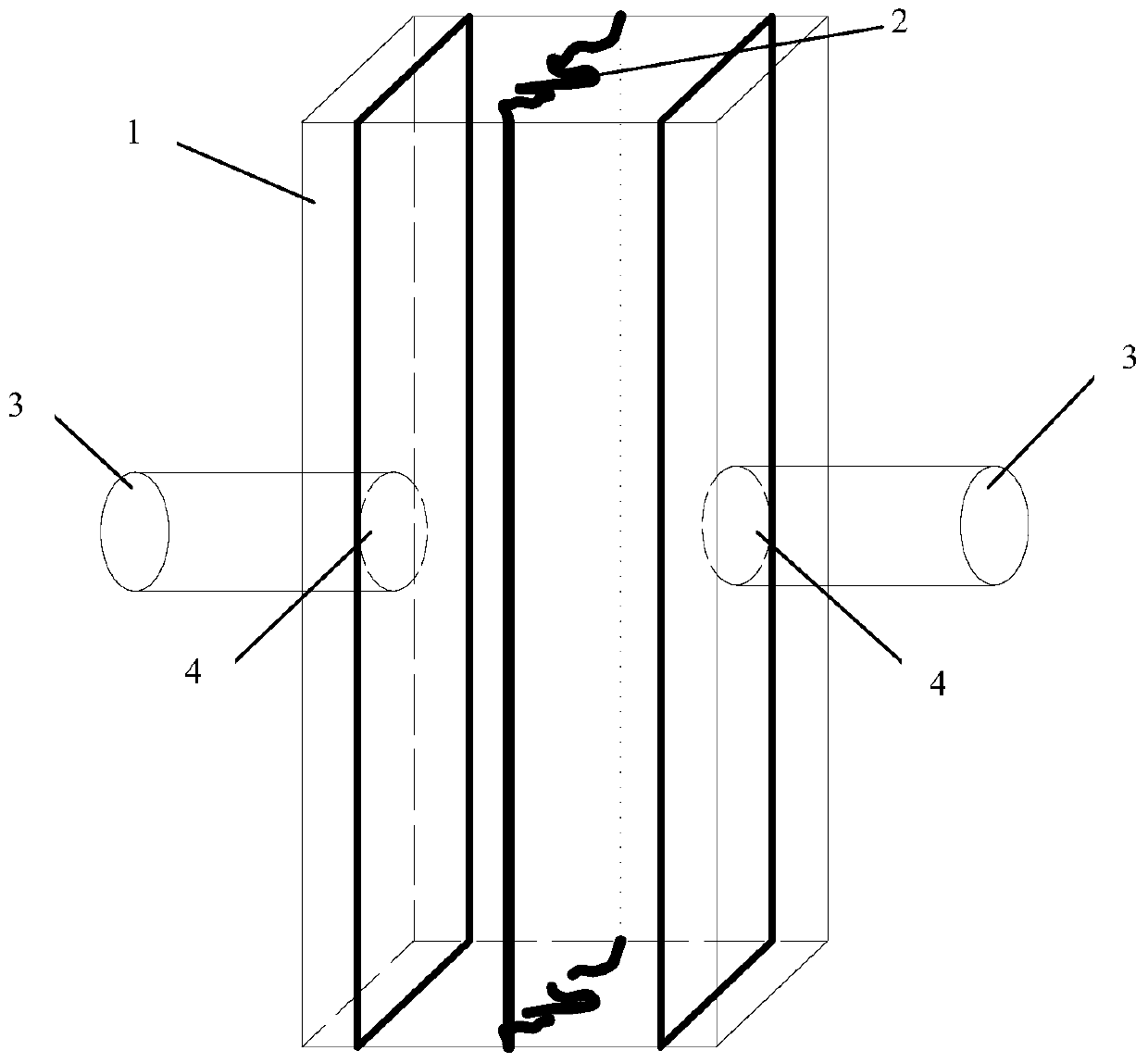

[0049] The prefabrication method that the present invention adopts is: the method for prefabricating the joint surface of standard roughness in the quasi-rock specimen includes the processing of the joint surface mold and the preparation of the rock specimen containing the rough joint surface; the joint surface mold includes the standard joint template obtained by cutting , Special processing groove and screw, the fixed hole with internal thread is processed at the geometric center of the standard joint formwork, and the positioning hole is reserved on the processing groove, which is used for the screw to adjust the distance between the two steel plates of the standard joint formwork to make joints The material of the sheet is a composite material, and the rock-like material has certain fluidity during pouring.

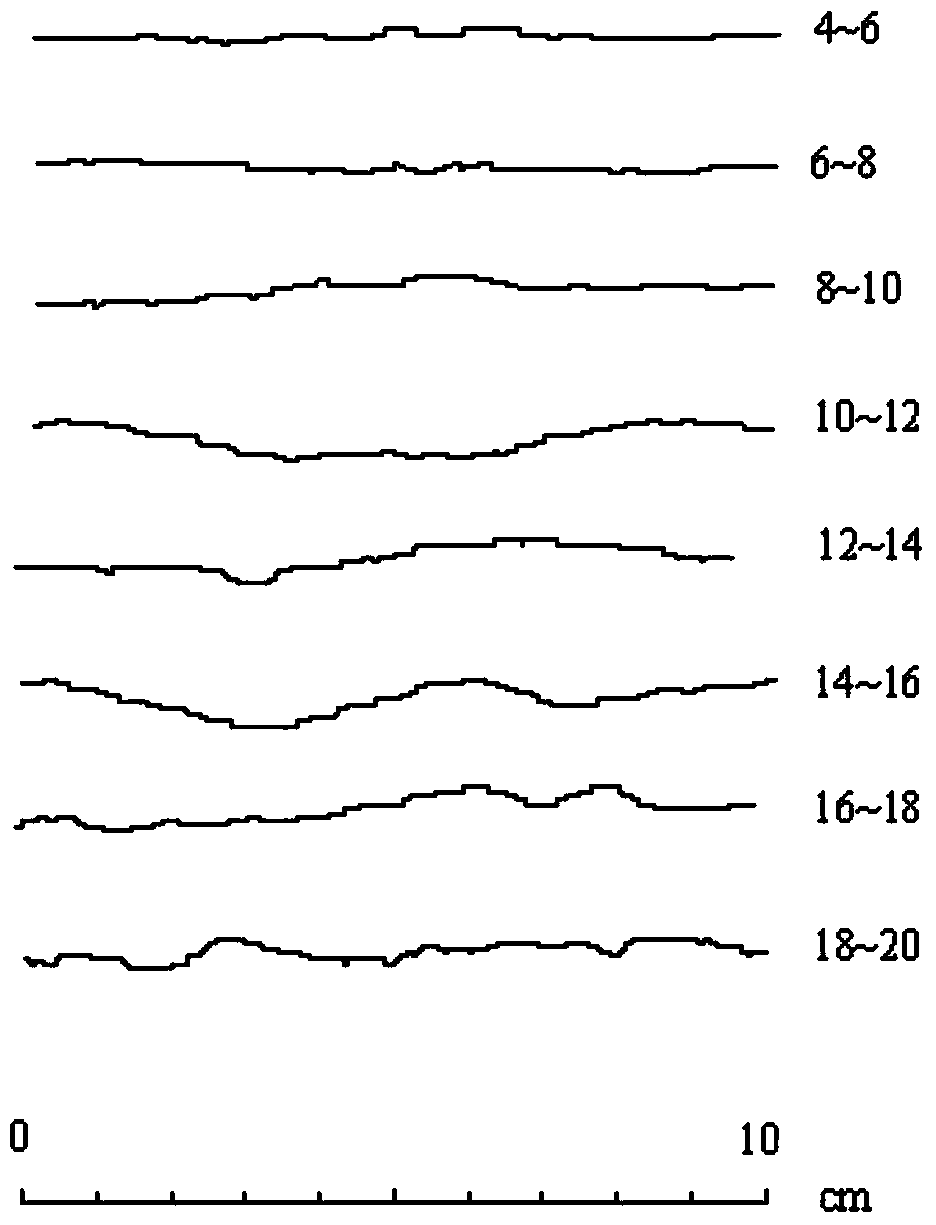

[0050] Furthermore, the joint surface morphology of the standard joint template is digitized according to the 10 JRC standard roughness contour curves given by N. Bart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com