Composite electrolyte membrane for oxygen production

A technology of composite electrolyte membrane and electrolyte layer, which is applied in the field of composite electrolyte membrane, can solve the problems of mixed conductor oxygen permeable membranes that are difficult to realize thin film, long oxygen dialysis path, difficult to practical application, etc., to achieve industrial application and small internal resistance , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

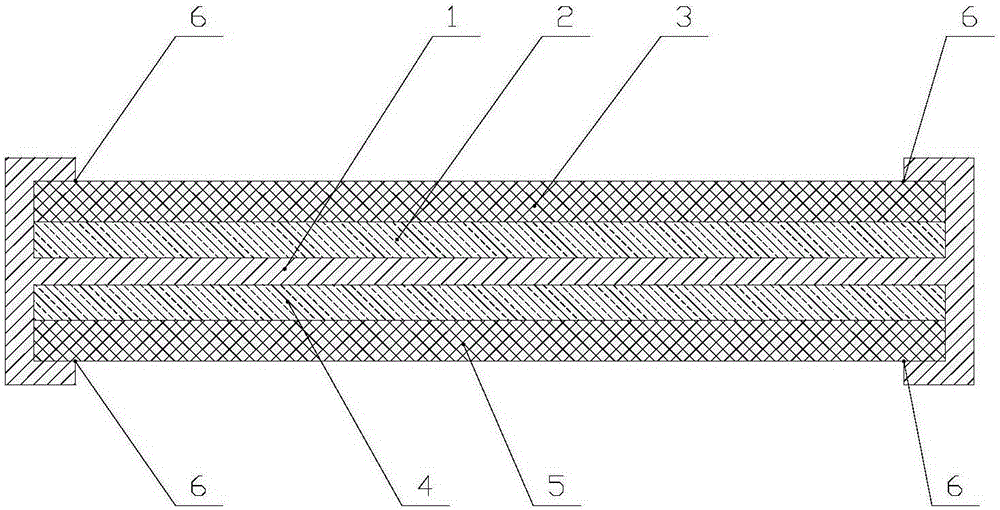

[0026] figure 1 Shown is an embodiment of a composite electrolyte membrane for oxygen production according to the present invention. On one side of the electrolyte layer 1, there are active cathode layer 2 and cathode support layer 3 from inside to outside; on the other side of the electrolyte layer 1, there are The active anode layer 4 and the anode support layer 5 are in sequence from the inside to the outside; the electrolyte layer 1 is bifurcated at the edge, and covers the two ends of the outer cathode support layer 3 / anode support layer 5 respectively to form a sealing edge 6 . The active cathode layer 2, the active anode layer 4, the cathode support layer 3, and the anode support layer 5 are all porous structures with a porous skeleton, and conductive materials are attached to the inner walls of the pores of the porous skeleton.

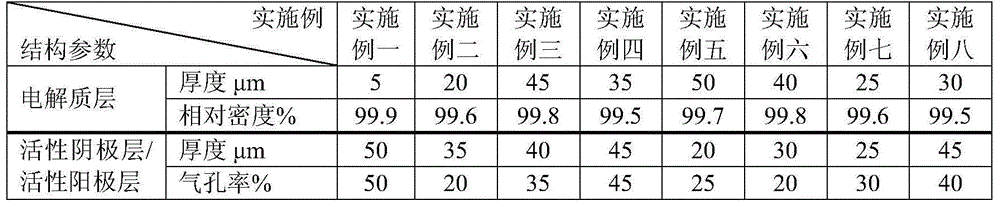

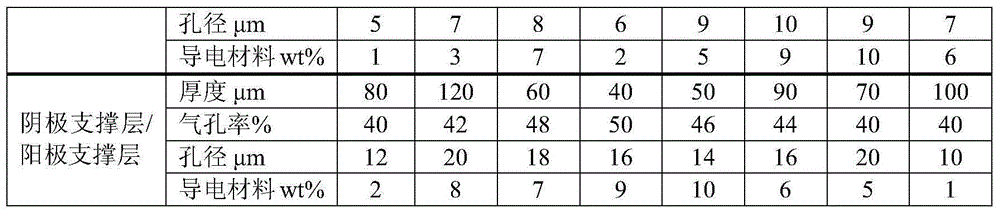

[0027] The structural parameters of the composite electrolyte membranes of various embodiments of the present invention are shown in Table 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com