Self-checking power distribution cabinet

A power distribution cabinet, voltage technology, applied in the direction of electrical components, circuit devices, emergency protection circuit devices, etc., can solve the problems of maintenance personnel damage, filler damage, grounding resistance increase, etc., to reduce the risk of damage, The effect of improving ionization ability and reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] refer to Figure 1 to Figure 8 Shown, the embodiment is described further.

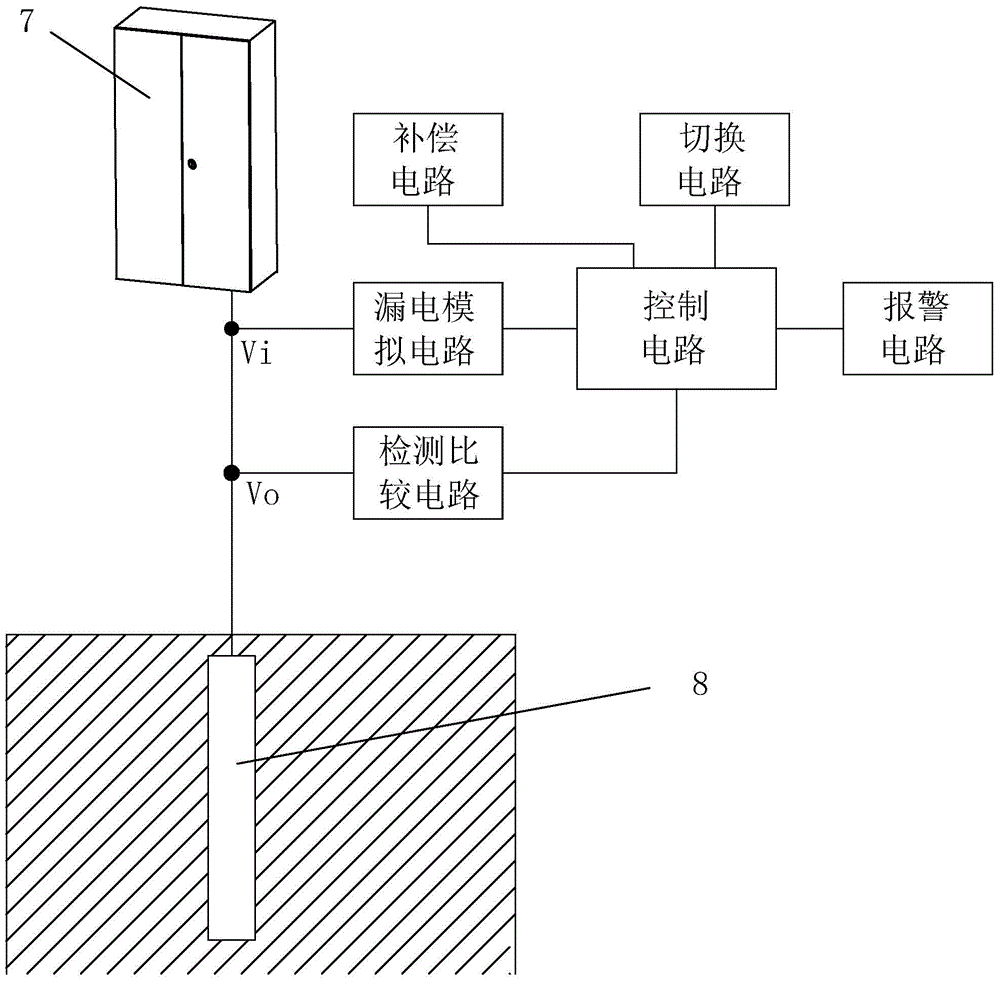

[0054] A self-inspection power distribution cabinet disclosed by the present invention includes a cabinet body 7 and an ion ground electrode 8, and the cabinet body 7 is connected to the ion ground electrode 8. When the ion ground electrode 8 is installed, the buried depth of the top surface of the ion ground electrode 8 should not If it is less than 0.6m, the angle steel and steel pipe ground electrodes should be arranged vertically. Except for the ion ground electrode 8, the lead wires of the ion ground electrode 8 should be treated with anti-corrosion treatment; when galvanized flat steel is used, the bolt connection part of the lead wire should be painted with anti-corrosion paint At the same time, in order to reduce the shielding effect of adjacent ground electrodes, the distance between vertical ground electrodes should not be less than twice its length, the distance between horizontal gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com