Asynchronous oscillation suppression method of separately controlled doubly fed electric machine and doubly fed electric machine system of asynchronous oscillation suppression method

A doubly-fed motor and controller technology, applied in the control system, motor parameter estimation/correction, slip frequency control, etc., can solve problems such as unstable characteristics and limit the industrial application of the control system, and solve the problem of easy out-of-step , improve stability, improve the effect of rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In the embodiment of the present invention, a method for suppressing out-of-step oscillation of a separately controlled doubly-fed motor and a doubly-fed motor system using the method are provided.

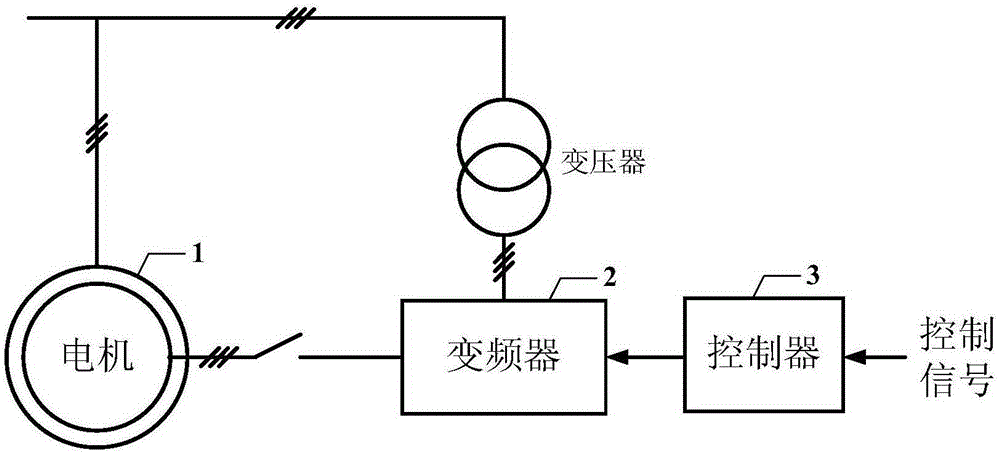

[0015] In some embodiments of the present invention, the schematic diagram of the separately controlled doubly-fed motor system can be as figure 1 Shown. In these embodiments, the doubly-fed motor system may include a doubly-fed motor 1, a frequency converter 2, and a controller 3. A frequency converter 2 (for example, a four-quadrant frequency converter) is connected to the doubly-fed motor 1. The controller 3 is connected to the inverter 2 and controls the operation of the doubly-fed motor 1 through the inverter 2 based on the received control signal.

[0016] although figure 1 It is displayed in a way that the controller 3 and the inverter 2 are separated, but it should be understood figure 1 It is only a schematic structural diagram for the convenience of description, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com