Silage processing method

A processing method and silage technology, applied in animal feed, animal feed, applications, etc., to achieve the effects of simple silage equipment, increased appetite and feed intake, and improved shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

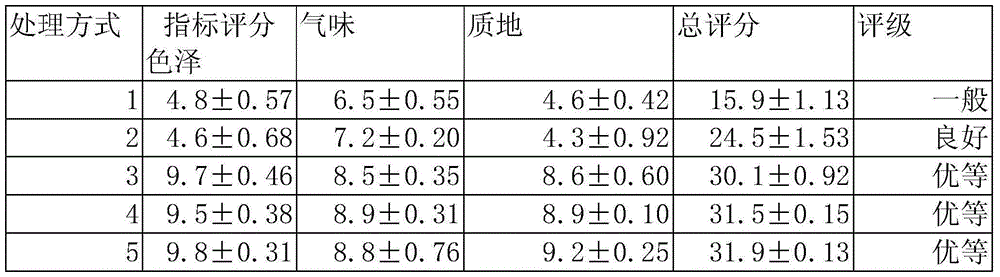

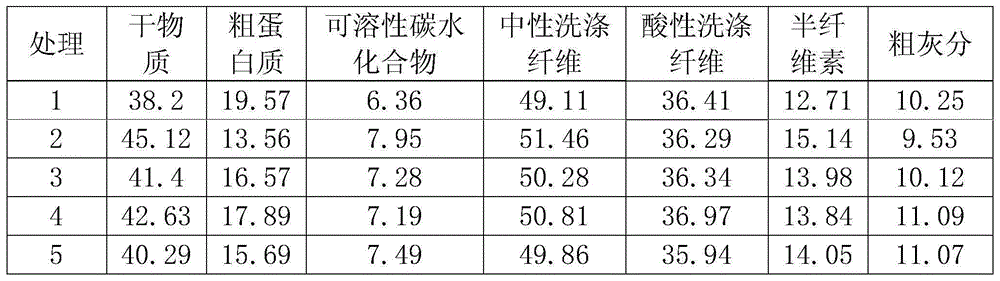

Examples

Embodiment 1

[0013] A kind of processing method of silage, concrete steps are as follows:

[0014] (1) Cutting: Cut the alfalfa and naked oats that are in the initial flowering stage and grain filling stage when they are cut, and then choose sunny days to naturally dry the harvested alfalfa and naked oats until the water content is 65%;

[0015] (2) Chopping: Cut alfalfa and naked oats into small pieces with a length of 2cm. Those with a lot of water and soft texture can be slightly longer, and those with less water and hard texture can be slightly shorter;

[0016] (3) Silage: Fully mix naked oats and alfalfa according to the mixed storage weight ratio of 2:1, put them into plastic bags, each bag weighs 900g, vacuumize and seal them, and store them for 60 days at 25°C to obtain the silage of the present invention. silage.

Embodiment 2

[0018] A kind of processing method of silage, concrete steps are as follows:

[0019] (1) Cutting: Cut the alfalfa and naked oats that are in the initial flowering stage and the filling stage when they are cut, and then choose sunny days to naturally dry the cut alfalfa and naked oats until the water content is 50%;

[0020] (2) Chopping: Cut alfalfa and naked oats into small pieces with a length of 2.5cm. Those with a lot of water and soft texture can be slightly longer, and those with less water and hard texture can be slightly shorter;

[0021] (3) Silage: Fully mix naked oats and alfalfa according to the mixed storage weight ratio of 3:3 and put them into plastic bags. silage.

Embodiment 3

[0023] A kind of processing method of silage, concrete steps are as follows:

[0024] (1) Cutting: Cut the alfalfa and naked oats that are in the initial flowering stage and the filling stage when they are cut, and then choose sunny days to naturally dry the cut alfalfa and naked oats until the moisture content is 55%;

[0025] (2) Chopping: Cut alfalfa and naked oats into small pieces with a length of 1.5cm;

[0026] (3) Silage: Fully mix naked oats and alfalfa according to the mixed storage weight ratio of 4:3, put them into plastic bags, each bag weighs 1100g, vacuumize and seal them, and store them for 65 days at 23°C to obtain the silage of the present invention. silage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com