Casting method for brake booster vacuum pump shell

A technology for booster vacuum pumps and shells, which is applied in the casting field of brake booster vacuum pump shells, can solve problems such as poor corrosion resistance, unreasonable pressure control, and air entrapment, and achieve improved mechanical properties of castings, reduced microstructure looseness, strong Effect of heat feeding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

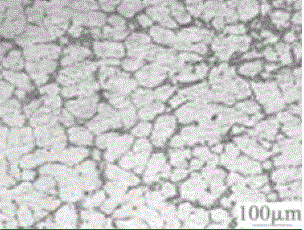

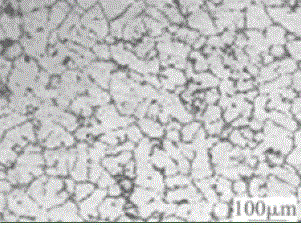

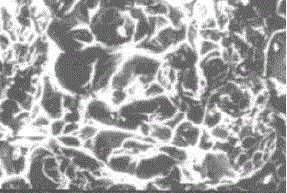

Image

Examples

Embodiment 1

[0017] A casting method for a brake booster vacuum pump casing, which is carried out according to the following steps:

[0018] Step 1: (1) Drying: First remove the residual coating and oxide layer of the melting tool, clean the melting tool first, spray a layer of protective coating evenly on the surface after preheating at 350°C, and then keep it at 400°C for more than 0.5 hours to dry until it turns yellow;

[0019] (2) Preheating and dehumidification: industrial additives need to be fully dehydrated and dried. The smelting equipment should be preheated before use to reduce moisture and other substances that increase the gas content of the melt. The preheating and dehumidification treatment is to put industrial additives in 100°C for 30 minutes;

[0020] Step 2: Smelting: According to the given weight ratio of ingredients, add 70-75% of pure aluminum and 10-20% of solid silicon into the induction melting furnace at the same time, raise the temperature to 1550-1600 degrees,...

Embodiment 2

[0024] A casting method for a brake booster vacuum pump casing, which is carried out according to the following steps:

[0025] Step 1: (1) Drying: First remove the residual coating and oxide layer of the melting tool, clean the melting tool first, spray a layer of protective coating evenly on the surface after preheating at 400°C, and then keep it at 600°C for more than 0.5 hours to dry until it turns yellow;

[0026] (2) Preheating and dehumidification: industrial additives need to be fully dehydrated and dried. The smelting equipment should be preheated before use to reduce moisture and other substances that increase the gas content of the melt. The preheating and dehumidification treatment is to put industrial additives in 150°C for 30 minutes;

[0027] Step 2: Smelting: According to the given weight ratio of ingredients, add 70-75% of pure aluminum and 10-20% of solid silicon into the induction melting furnace at the same time, raise the temperature to 1550-1600 degrees,...

Embodiment 3

[0031] A casting method for a brake booster vacuum pump casing, which is carried out according to the following steps:

[0032]Step 1: (1) Drying: First remove the residual coating and oxide layer of the melting tool, clean the melting tool first, spray a layer of protective coating evenly on the surface after preheating at 375°C, and then keep it at 500°C for more than 0.5 hours to dry until it turns yellow;

[0033] (2) Preheating and dehumidification: industrial additives need to be fully dehydrated and dried. The smelting equipment should be preheated before use to reduce moisture and other substances that increase the gas content of the melt. The preheating and dehumidification treatment is to put industrial additives in 130°C for 25 minutes;

[0034] Step 2: Smelting: According to the given weight ratio of ingredients, add 70-75% of pure aluminum and 10-20% of solid silicon into the induction melting furnace at the same time, raise the temperature to 1550-1600 degrees, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com