Weighing support system of garbage compressor

A garbage compactor and support system technology, applied to presses, manufacturing tools, etc., can solve problems such as high installation accuracy requirements, inconvenient maintenance, and large installation errors, so as to improve equipment safety performance, reduce maintenance costs, and maintain convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

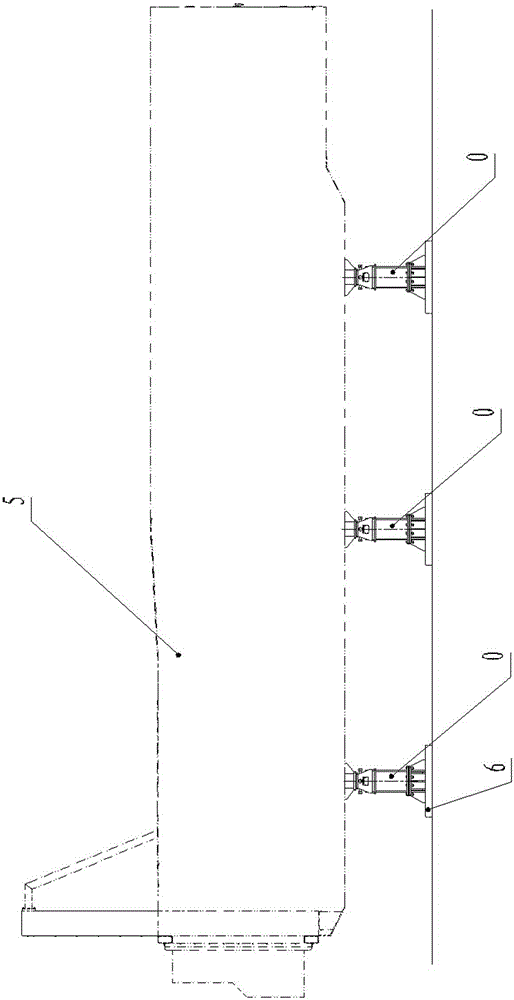

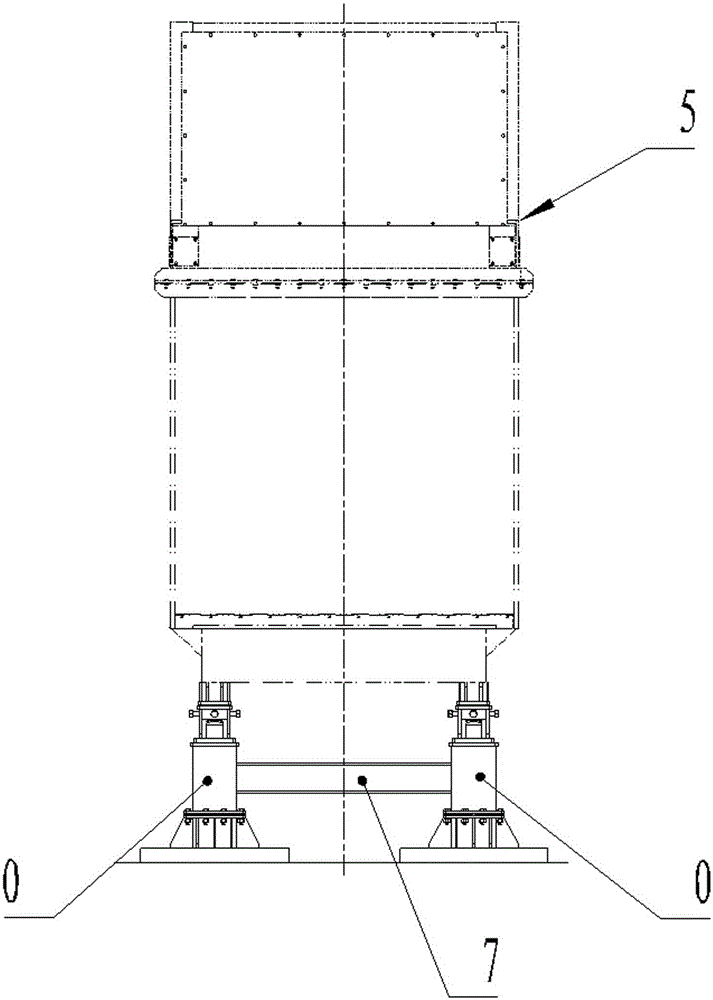

[0032] see Figure 1 to Figure 7 , is an embodiment of the floating weighing support system of the garbage compressor, which is composed of a plurality of contact support mechanisms 0 cooperating with each other, and a connecting beam 7 can also be added between the two contact support mechanisms 0, The strength and stability of the floating weighing support system of the garbage compactor are further enhanced. One end of the contact support mechanism is firmly welded to the garbage compressor 5 , and the other end is firmly welded to the foundation embedded part 6 .

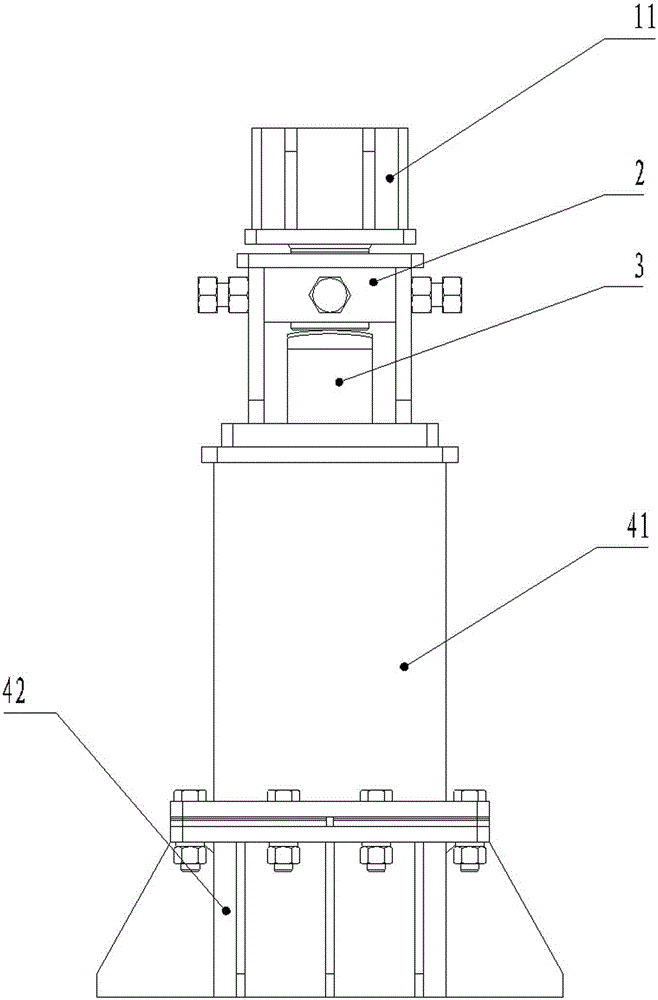

[0033] The contact support mechanism includes a combination support base 4 , a connection base 11 for connecting a garbage compressor, and a load cell 3 . The combined support base includes a base 42 and an upper support base 41, the upper support base is connected and fixed with the base by a plurality of bolts, the upper end of the upper support base 41 is fixed with a weighing mounting base 2, and the load c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com