Flapping-wing micro air vehicle based on fan driving

A flapping-wing aircraft and drive technology, applied in the field of flapping-wing bionic aircraft, can solve the problems of large input power, large input power, and heavy weight of the drive, and achieve the effects of simple drive control, convenient processing and manufacturing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] This embodiment is a micro-flapping-wing aircraft driven by a fan.

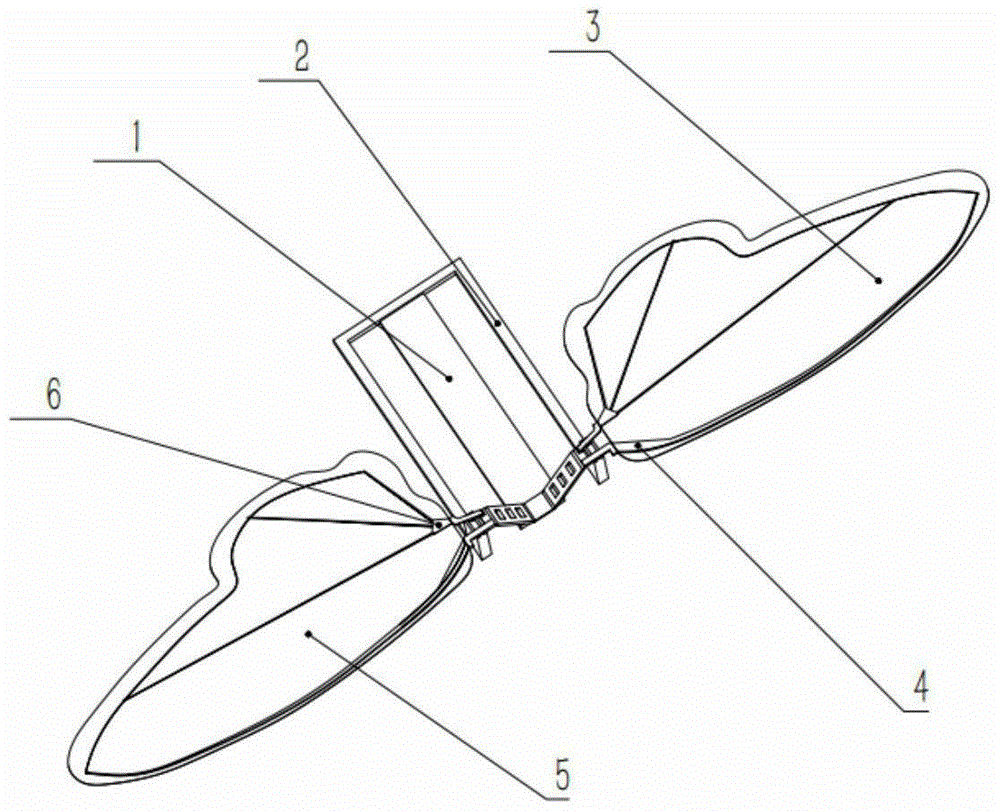

[0019] refer to Figure 1 ~ Figure 4 The micro-flapping wing aircraft combines the fan driver and the hinge linkage mechanism into one body. The hinge linkage mechanism 2 on both sides of the fan driver is symmetrically arranged, and combined with the passive torsion structure, the flapping and twisting of the wings on both sides is realized.

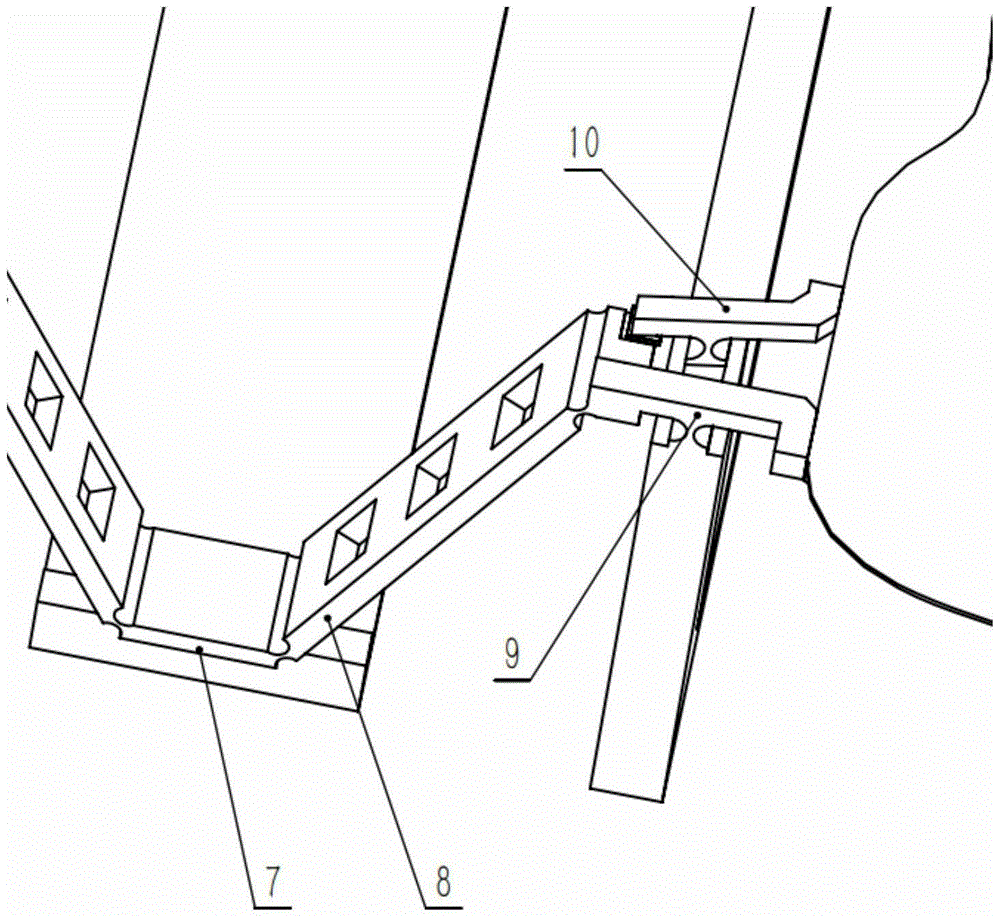

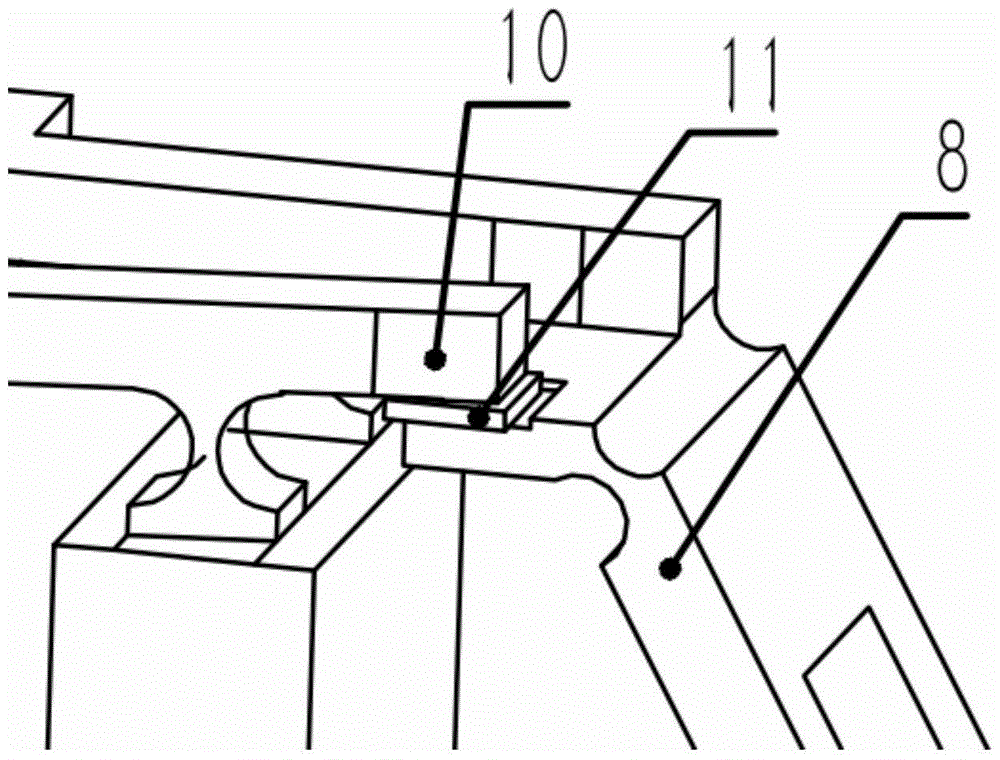

[0020] Present embodiment flapping wing aircraft is by fan driver 1, hinge link mechanism 2, right wing membrane 3, left wing membrane 5, wing leading edge 4, wing trailing edge 6, driver 12, driving fan 13, drive connecting Rod 7, two push rods 8, two control rods 9, two torsion control rods 10, and two wear-resistant pads 11; the fan driver 1 is installed in the hinge linkage mechanism 2, and one end of the fan driver 1 is connected to the hinge The inner end surface of the linkage mechanism 2 is fixedly connected, and the drive link 7 is fixedly installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com