Preparation method for black phosphorus quantum dot-graphene nanosheet three dimensional composite

A technology of graphene nanosheets and composite materials, which is applied in the preparation of three-dimensional composite materials of black phosphorene quantum dots and graphene nanosheets, and in the field of composite material preparation, can solve problems such as affecting electrical properties and reducing electron mobility, and achieve large The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

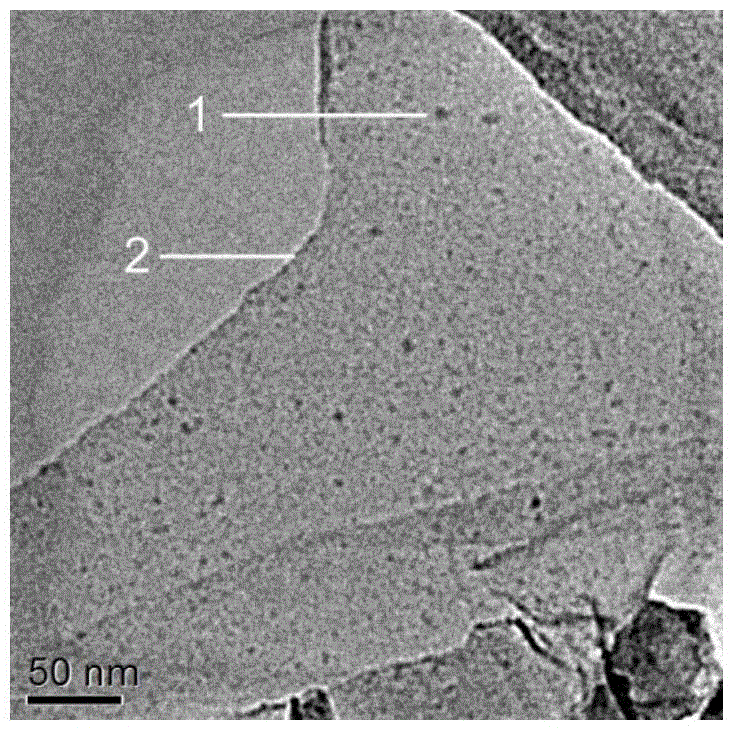

[0017] (1) First, the 0.001 mg / mL ethanol solution of black phosphorene quantum dots prepared by the shear pulverization method is added to the ethanol solution of 1 mg / mL graphene oxide, and the method of mechanical stirring is used to make the black phosphorene quantum dots adsorb on The surface of graphene oxide, stirring time is 1min.

[0018] (2) Then take 10 mL of black phosphorene quantum dots and graphene oxide ethanol solution and pour it into a polytetrafluoroethylene-lined autoclave with a volume of 25 mL, and carry out solvothermal reaction at 100 °C. After the reaction is finished, a bulk colloidal composite material filled with ethanol is obtained.

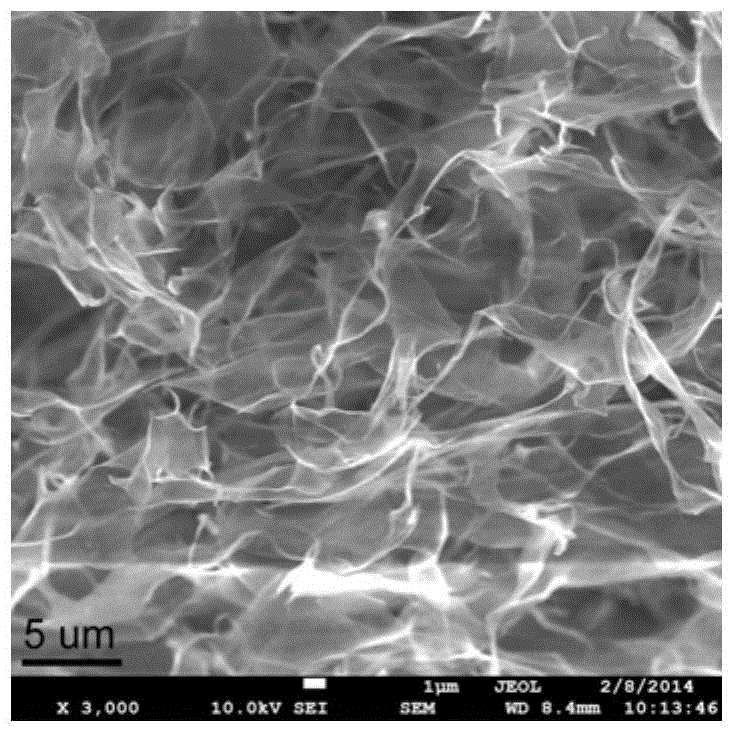

[0019] (3) After the block colloid is taken out from the reaction kettle, it is immersed in deionized water for 1 hour, so that the ethanol and water inside the block colloid material are exchanged with each other. Take out the block colloid filled with water and freeze-dry for 6 hours to obtain a porous black phosp...

Embodiment 2

[0022] (1) First, the 0.01mg / mL ethanol solution of black phosphorene quantum dots prepared by the shear pulverization method is added to the ethanol solution of 3 mg / mL graphene oxide, and the method of mechanical stirring is used to make the black phosphorene quantum dots adsorb on The surface of graphene oxide, stirring time is 30min.

[0023] (2) Then take 50 mL of black phosphorene quantum dots and graphene oxide ethanol solution and pour it into a polytetrafluoroethylene-lined autoclave with a volume of 100 mL, and carry out solvothermal reaction at 150 ° C. After the reaction is finished, a bulk colloidal composite material filled with ethanol is obtained.

[0024] (3) After the block colloid is taken out from the reaction kettle, it is immersed in deionized water for 12 hours, so that the ethanol and water inside the block colloid material are exchanged with each other. Take out the massive colloid filled with water and freeze-dry for 36 hours to obtain a porous black...

Embodiment 3

[0029] (1) First, the 0.01mg / mL ethanol solution of black phosphorene quantum dots prepared by the shear pulverization method is added to the ethanol solution of 5 mg / mL graphene oxide, and the method of mechanical stirring is used to make the black phosphorene quantum dots adsorb on The surface of graphene oxide, stirring time is 60min.

[0030] (2) Then take 80 mL of black phosphorene quantum dots and graphene oxide ethanol solution and pour it into a polytetrafluoroethylene-lined autoclave with a volume of 150 mL, and carry out solvothermal reaction at 180 ° C. After the reaction is finished, a bulk colloidal composite material filled with ethanol is obtained.

[0031] (3) After the block colloid is taken out from the reaction kettle, it is immersed in deionized water for 48 hours, so that the ethanol and water inside the block colloid material are exchanged with each other. Take out the massive colloid filled with water and freeze-dry it for 48 hours to obtain a porous bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com