Waterproof lightweight concrete prefabricated slab

A technology of lightweight concrete and prefabricated panels, applied in the field of building materials, can solve the problem that the technical grade cannot meet the requirements, and achieve the effects of reducing the possibility of thermal expansion and deformation, reducing the cost of foundation construction, and improving the fire resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

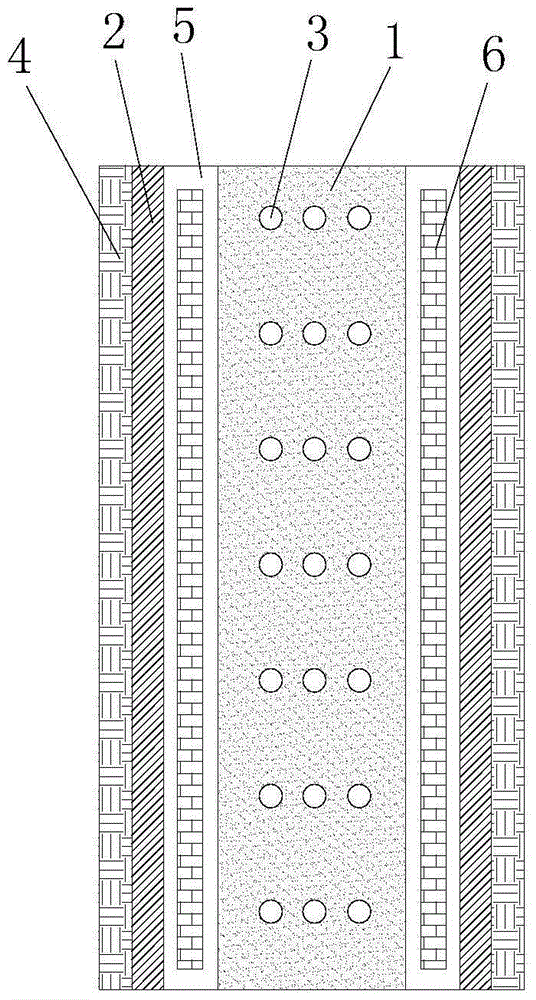

[0014] This embodiment provides a kind of refractory lightweight concrete prefabricated panel, the structure is as follows figure 1 As shown, it includes foam concrete layer 1, refractory filler layer 2, insulation layer, keel frame 3 and surface layer 4. The surface layer is arranged on the upper and lower sides of the prefabricated slab, and the upper and lower surface layers are arranged in sequence from bottom to top. Filling layer, insulation layer, concrete layer, insulation layer and refractory filler layer, the thickness of concrete accounts for 1 / 2 of the thickness of the entire concrete prefabricated slab; the keel reinforcement layer includes a grid frame made of carbon fiber guide rods and covered in a grid-like The frame is made of wire mesh, the keel frame 3 is covered in a concrete layer, the insulation layer is composed of a mortar layer 5 covered with a polyurethane foam layer 6, and the surface layer is made of glass fiber mesh and carbon fiber mesh.

[0015]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com