Variable valve lift mechanism and its control method

A valve lift, variable technology, applied in the direction of engine control, mechanical equipment, engine components, etc., can solve the problems of increasing manufacturing costs, pressing rocker arms in advance or delay, affecting the working efficiency and fuel economy of internal combustion engines, etc. Low, linear power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

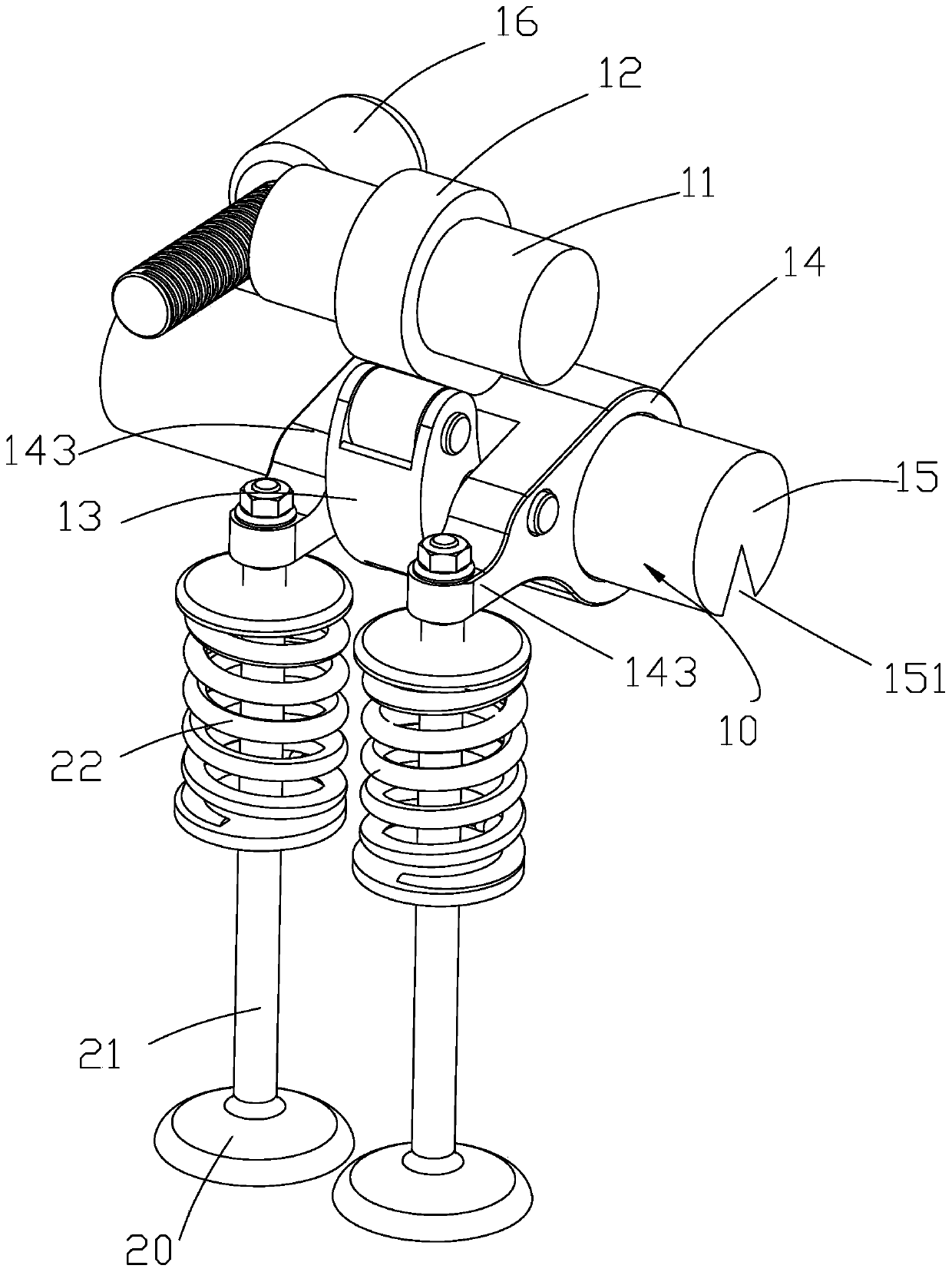

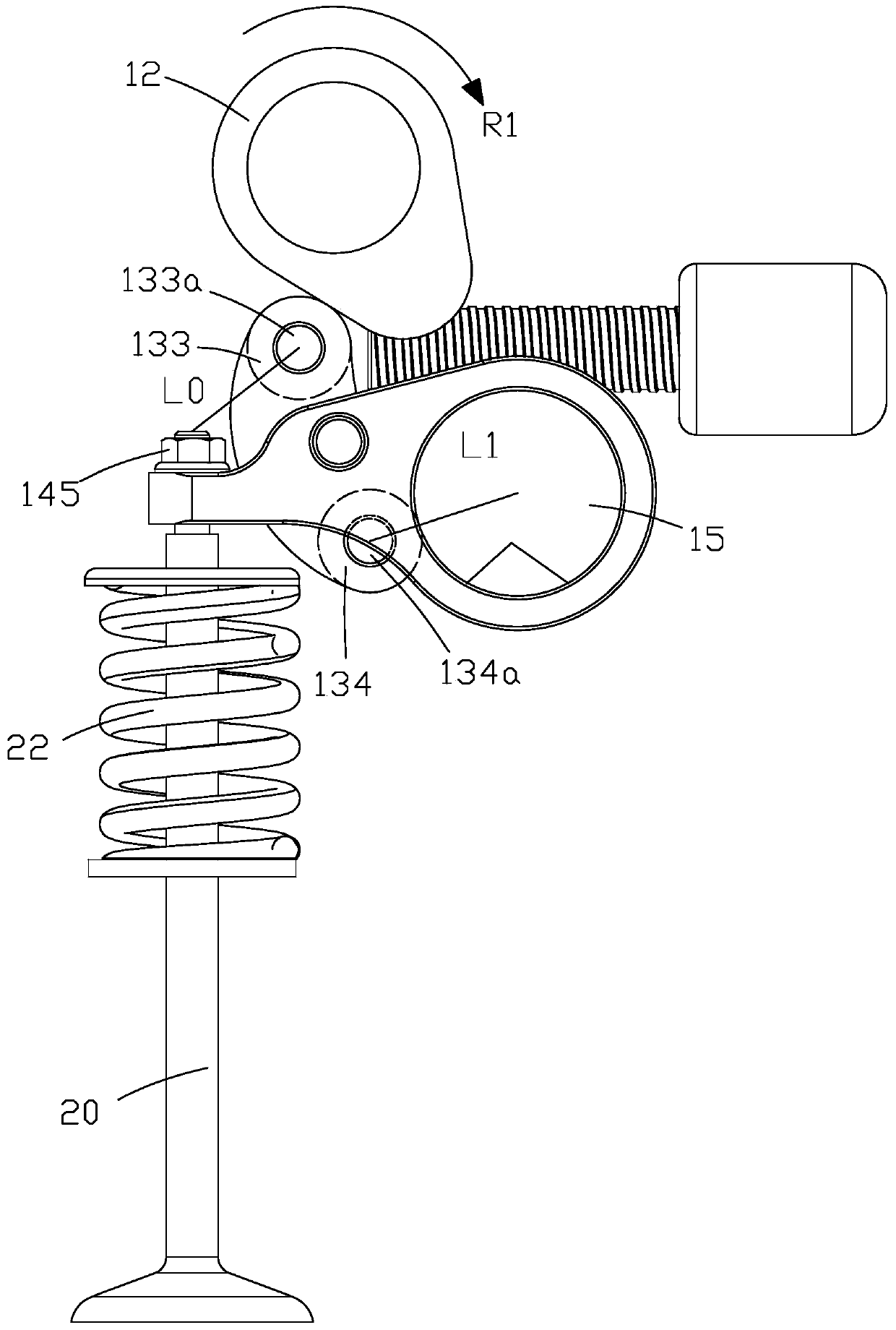

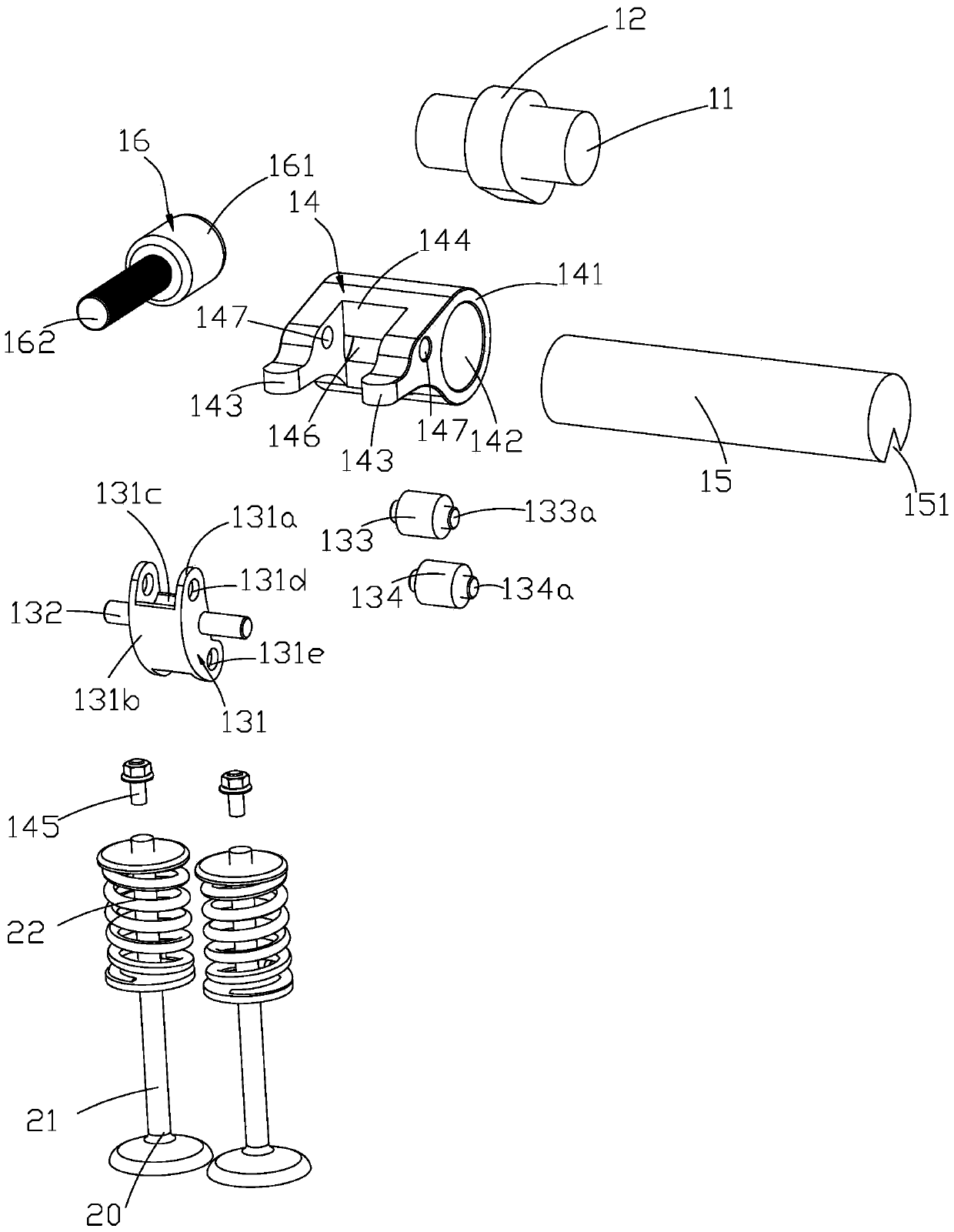

[0076] Figure 1-3 The variable valve lift mechanism 10 in the first embodiment of the present invention is shown, which is used to open and close a valve 20; wherein, the valve 20 can constitute an intake or exhaust system of an internal combustion engine, for example. The valve 20 specifically includes a valve stem 21 and a valve spring 22 sleeved on the valve stem 21.

[0077] Such as Figure 1-3 As shown, the variable valve lift mechanism 10 includes a rotatable camshaft 11, a cam 12 mounted on the camshaft 11, a rocker arm assembly 13 driven by the cam 12 to swing, and a swingable valve 20 to open and close. The swing assembly 14 and the feed shaft 15 rotatably accommodated in the swing assembly 14. In use, the rotation of the camshaft 11 will drive the cam 12 to rotate and drive the rocker arm assembly 13 to swing synchronously in opposite directions, so that the rocker arm assembly 13 drives the swing assembly 14 to swing, thereby driving the opening and closing of the val...

Embodiment 2

[0098] Figure 7-9 The specific structure of the variable valve lift mechanism in the second embodiment of the present invention is shown. Such as Figure 7-9 As shown, the variable valve lift mechanism 10 also includes a cam shaft 11, a cam 12, a rocker arm assembly 13, a swing assembly 14, a feed shaft 15 and a rotation drive assembly 16. Among them, the structures of the cam shaft 11, the cam 12, the rocker arm assembly 13, the feed shaft 15 and the rotation drive assembly 16 are the same as those of the corresponding parts in the first embodiment, and will not be repeated here. The difference between the second embodiment and the first embodiment is that, for the swing assembly 14, the end of each swing arm 143 away from the swing body 141 is further connected to a roller bracket 148, and the roller bracket 148 can also rollably accommodate. Equipped with swing arm roller 149. Wherein, the valve 20 further includes a valve top cup 23 in this embodiment. The valve cleara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com